Method used for synchronous production of cyclohexanone-oxime and acetone

A technology of cyclohexanone oxime and cyclohexanone is applied in the field of simultaneous production of cyclohexanone oxime and acetone, and achieves the effects of easy operation, simple process flow and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

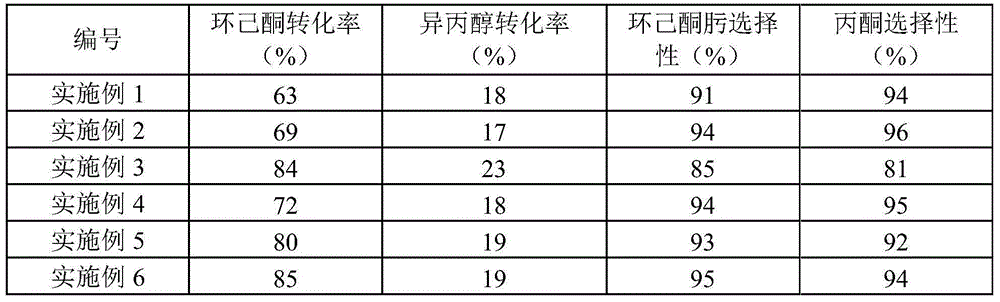

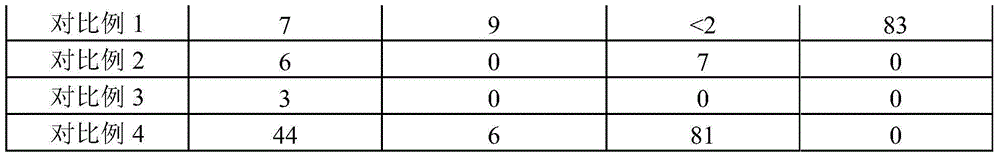

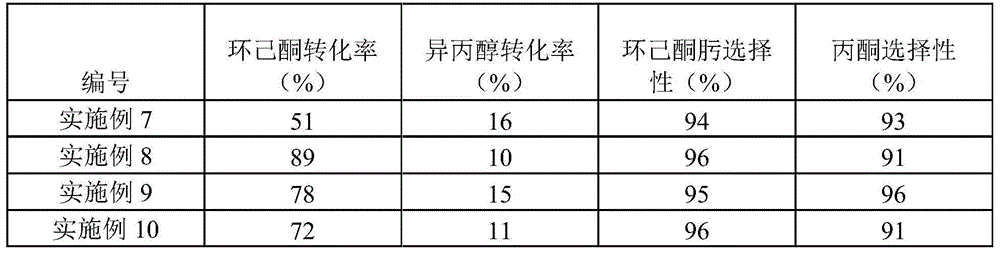

Examples

Embodiment 1

[0042] In the tank reactor, under an oxygen atmosphere (an atmosphere formed by oxygen with a purity of 99%), cyclohexanone, liquid ammonia and isopropanol are contacted with the original powder of titanium silicon molecular sieve TS-1 as a catalyst, Among them, the molar ratio of cyclohexanone to isopropanol is 1:5, the molar ratio of cyclohexanone to ammonia is 1:1.5, the weight ratio of cyclohexanone to catalyst is 20:1, the temperature is 90°C, and the pressure is 1.5MPa (gauge pressure), the oxygen partial pressure is 1.5MPa. After reacting for 2 hours, the mixture obtained was filtered, and the liquid mixture obtained was collected and analyzed by gas chromatography, thereby obtaining the conversion rate of cyclohexanone, the conversion rate of Virahol, the selectivity of cyclohexanone oxime and the selectivity of acetone, and the results were in Listed in Table 1.

Embodiment 2

[0044] Cyclohexanone was oxidized by the same method as in Example 1, except that a hollow titanium-silicon molecular sieve of equal mass was used instead of titanium-silicon molecular sieve TS-1, and the temperature was 60°C. The experimental results are listed in Table 1.

Embodiment 3

[0046] Cyclohexanone was oxidized by the same method as in Example 1, except that the reaction temperature was 120°C. The experimental results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com