Method for separating and purifying o-hydroxyl compound

A technology for separation and purification of adjacent hydroxyl groups, applied in quinone separation/purification, chemical/physical processes, ion exchange, etc., can solve the problems of difficult flotation separation of water-soluble targets, destruction of biological activity, large material consumption, etc., and achieve a simple and convenient system and method of operation, high purity, and effect of large upper phase volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

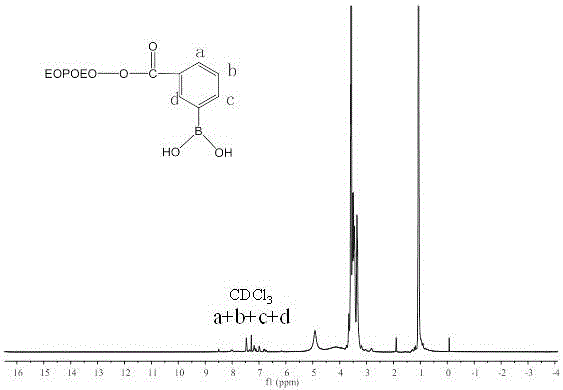

[0036] Example 1: Phenylboronic acid functionalized PEO 20 PPO 60 PEO 20 Synthesis

[0037] 0.12 g of m-carboxyphenylboronic acid was added to 17.50 mL of dichloromethane, and 124 μL of oxalyl chloride was added thereto after fully dissolving, and 4 drops of N,N-dimethylformamide were added dropwise to initiate the reaction. The obtained solution was stirred and reacted at room temperature for 12 h, and then the solvent was removed by rotary distillation under reduced pressure to obtain 0.12 g of 3-formyl chloride phenylboronic acid as a yellow liquid product. Dissolve 0.12 g of the product 3-formyl chloride phenylboronic acid in 17.50 mL of dichloromethane to obtain solution A; dissolve 0.50 g of PEO 20 PPO 60 PEO 20 Dissolved in 35.00 mL of dichloromethane, and to this was added 150 μL of triethylamine to obtain solution B. Then, all 17.50 mL of solution A was dropped into 35.00 mL of solution B under ice-water bath cooling. After the dropwise addition was complete, t...

Embodiment 2

[0042] Example 2: Separation and purification of o-hydroxy compounds by two-phase flotation system

[0043] (1) Add 0.1 mg of alizarin red and 8 g of K to a 50 mL colorimetric tube 2 HPO 4 , then add

[0044] 0.05g phenylboronic acid functionalized PEO prepared in Example 1 20 PPO 60 PEO 20 As a flotation collector and diluted with distilled water to 50 mL, the solution system was fully shaken and mixed evenly. The obtained solution was left to stand for 15 min and then poured into the flotation column, then 5 mL of n-propanol was added, the gas flow was adjusted to 5 mL / min and the flotation started. After 10 min, the system separated into two phases.

[0045] (2) After phase separation, record the volume of the upper phase as 2.9 mL, and use the following method to determine the concentration of alizarin red: take 1.00 mL of the sample to be tested and mix it with 9.00 mL of citric acid-sodium citrate buffer solution (pH=4) at 10.00 mL plastic centrifuge tube, shake t...

Embodiment 3

[0046] Example 3: Separation and purification of o-hydroxy compounds by two-phase flotation system

[0047] (1) Add 1 mg of Alizarin Red and 16 g of K to a 50 mL colorimetric tube 2 HPO 4 , then add

[0048] 0.4 g phenylboronic acid functionalized PEO prepared in Example 1 20 PPO 60 PEO 20 As a flotation collector and diluted with distilled water to 50 mL, the solution system was fully shaken and mixed evenly. The resulting solution was left standing for 15 min and then poured into the flotation column, followed by adding 5 mL of n-propanol, adjusting the gas flow to 25 mL / min and starting the flotation. After 50 min, the system separated into two phases.

[0049] (2) After phase separation, record the volume of the upper phase as 4.1 mL, and determine the concentration of alizarin red by the following method: Take 1.00 mL of the sample to be tested and mix it with 9.00 mL of citric acid-sodium citrate buffer solution (pH=4) at 10.00 mL plastic centrifuge tube, shake th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com