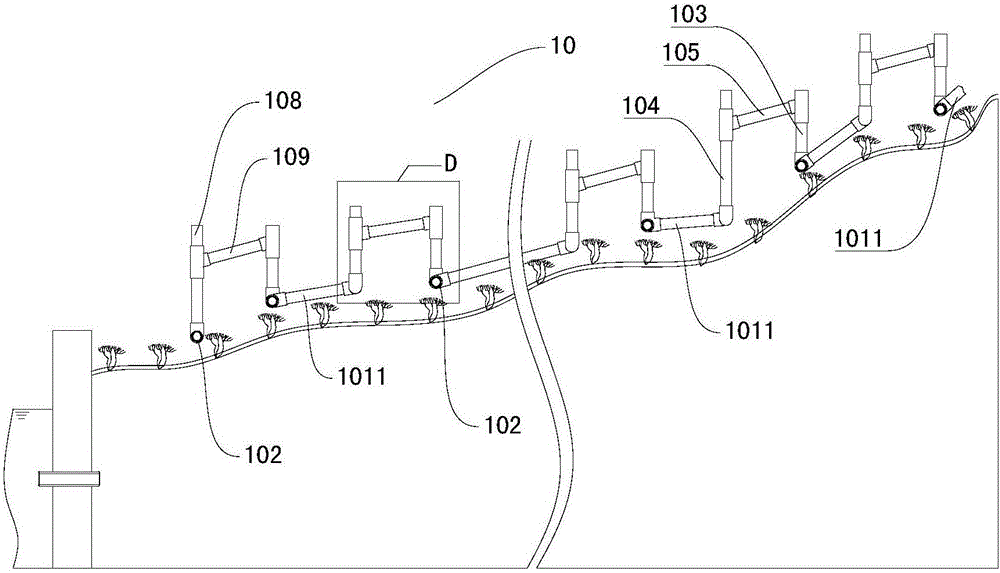

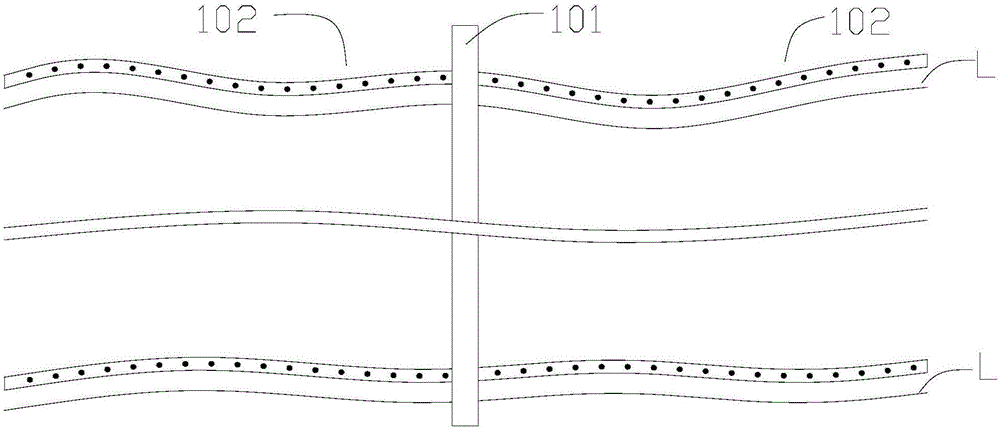

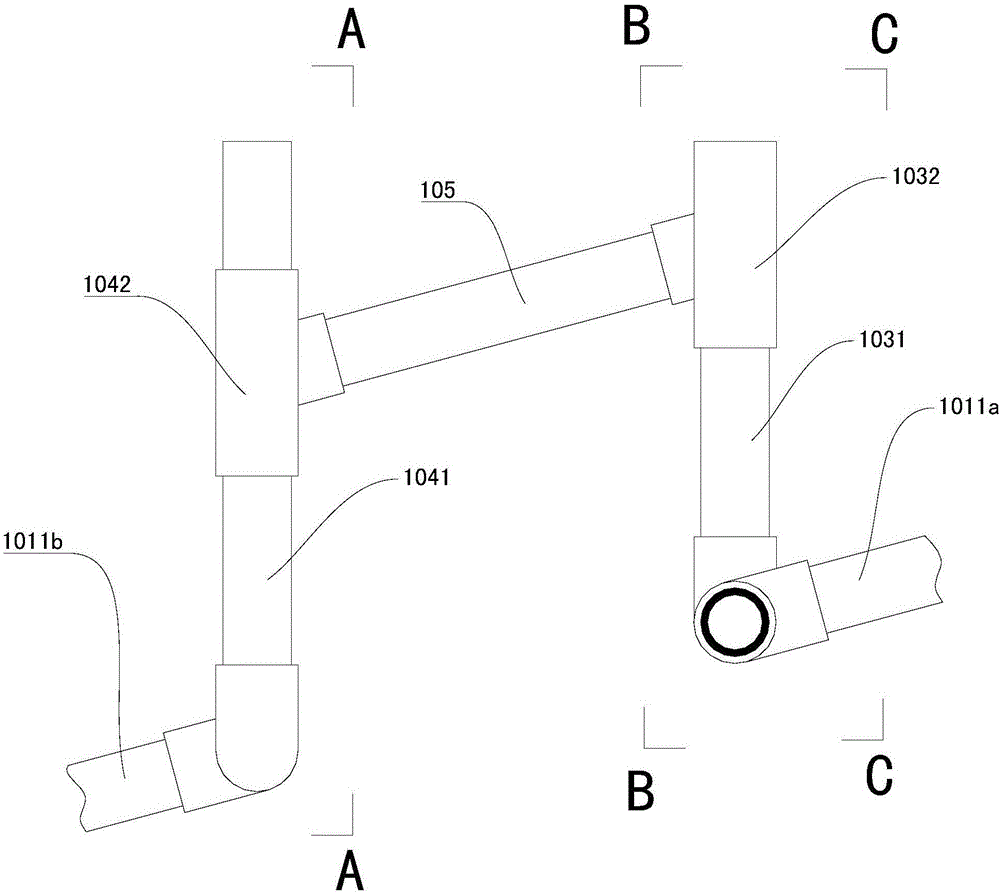

Low-pollution water quality deep purification system

A deep purification and low pollution technology, applied in the environmental field, can solve the problems of unsatisfactory removal of nitrogen and phosphorus, and achieve the effect of uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In order to achieve the effect of deep phosphorus removal, the present invention provides a phosphorus removal filler X-Phos matrix and its preparation method, X is defined as "removal", Phos represents phosphate, and CaO 2 , Attapulgite clay, adhesive and water balance are mixed and stirred in a certain proportion and pressed into cylindrical particles, which can be used as phosphorus removal fillers. Main raw material: CaO 2 Powder (CaO 2 Content 50%~60%), attapulgite clay, adhesive, water. The weight composition of the filler is: CaO2 Powder 50%~55%, natural attapulgite clay 5%~10%, modified attapulgite clay 30%~35%, adhesive 3%~6%, water 3%~6%. When the filler is finally formed, it is a cylinder with a bottom diameter of 5-50mm and a height of 5-50mm. The maximum phosphorus adsorption capacity is 200mg / g.

[0055] The adhesive is one or both of sodium silicate and polyvinyl alcohol adhesive.

[0056] In addition to the above-mentioned main raw materials, a smal...

Embodiment 1

[0069] Example 1: Laboratory static simulation experiment I

[0070] Potassium dihydrogen phosphate solution is prepared in the laboratory so that its TP is 1.2 mg / L, and a cylindrical packing with a diameter of 5 mm and a height of 10 mm is used. The preparation steps of the packing are the same as above, and the weight ratio of raw material components is: CaO 2 Powder 50%, natural attapulgite clay 8%, modified attapulgite clay 31%, sodium silicate 1%, polyvinyl alcohol adhesive 3%, water 4%, MgO 2 1%, activated carbon 1%, fly ash 1%. Take 1L of potassium dihydrogen phosphate solution, add two fillers, and take a water sample for testing after 8 hours. The results are shown in Table 1.

[0071] Table 1 Comparison of water quality

[0072] pH TP initial water quality 6.8 1.24mg / L Water quality after 8h 10.5 0.21mg / L

Embodiment 2

[0073] Embodiment 2: Laboratory static simulation experiment II

[0074] Potassium dihydrogen phosphate solution is prepared in the laboratory so that its TP is 1.2 mg / L, and a cylindrical packing with a diameter of 10 mm and a height of 20 mm is used. The preparation steps of the packing are the same as above, and the weight ratio of raw material components is: CaO 2 Powder 50%, natural attapulgite clay 6%, modified attapulgite clay 30%, activated carbon 5%, sodium silicate 1%, polyvinyl alcohol adhesive 4%, water 4%. Take 5L of potassium dihydrogen phosphate solution, add two fillers, and take a water sample for testing after 12 hours. The results are shown in Table 2.

[0075] Table 2 Water quality comparison

[0076] pH TP initial water quality 6.9 1.22mg / L Water quality after 8h 9.8 0.20mg / L

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com