Re-drying method for keeping aroma substances of tobacco leaves

A technology of aroma substances and tobacco leaves, which is applied in the field of rebaking to maintain the aroma substances of tobacco leaves, and can solve problems such as insufficient rebaking degree and excessive moisture in finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

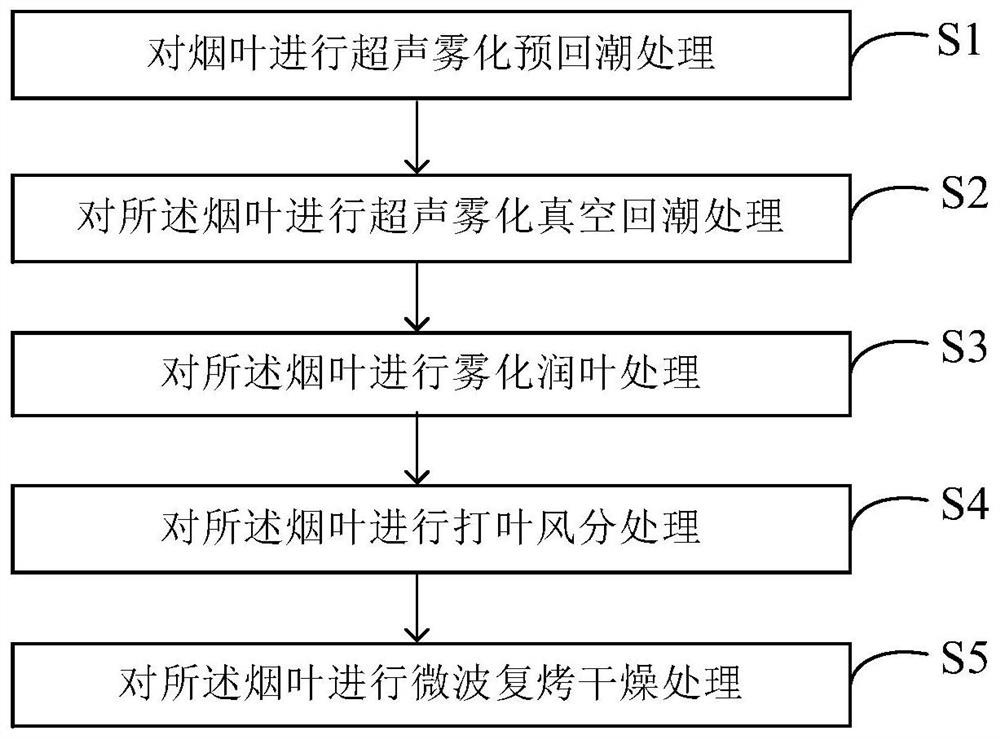

[0046] Considering that the current rebaking process is mostly a low-intensity process, by adjusting the rebaking temperature and other related parameters, although the aroma preservation effect can be achieved, it will lead to problems such as insufficient rebaking and excessive moisture in the finished product, and it is impossible to take into account the drying effect And the problem of fragrance retention effect. The invention provides a rebaking method for maintaining the aroma substances of tobacco leaves. Ultrasonic atomization pre-moisture can effectively increase the moisture content in the material preparation link, which is beneficial to reduce the subsequent moisture regain intensity and reduce the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com