Supporting and collecting mechanism

A material receiving mechanism and material supporting technology, which is applied in the direction of conveyor objects, stacking, transportation and packaging of objects, can solve the problems of inability to achieve orientation, positioning, transmission, automatic stepping and stacking, etc., and achieves a high degree of automation and stable operation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

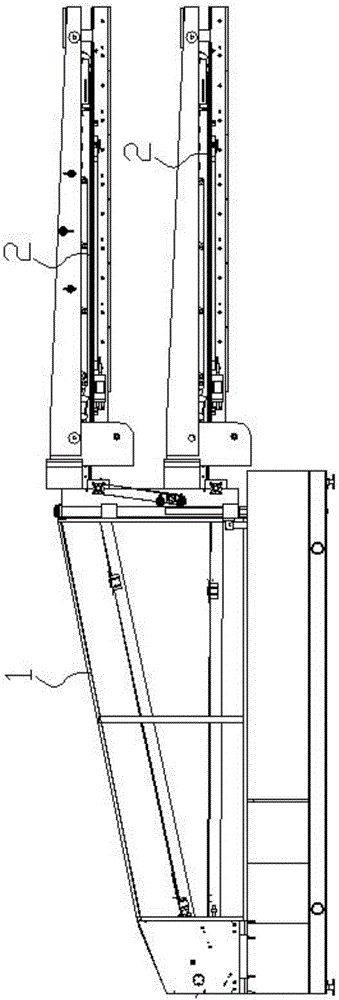

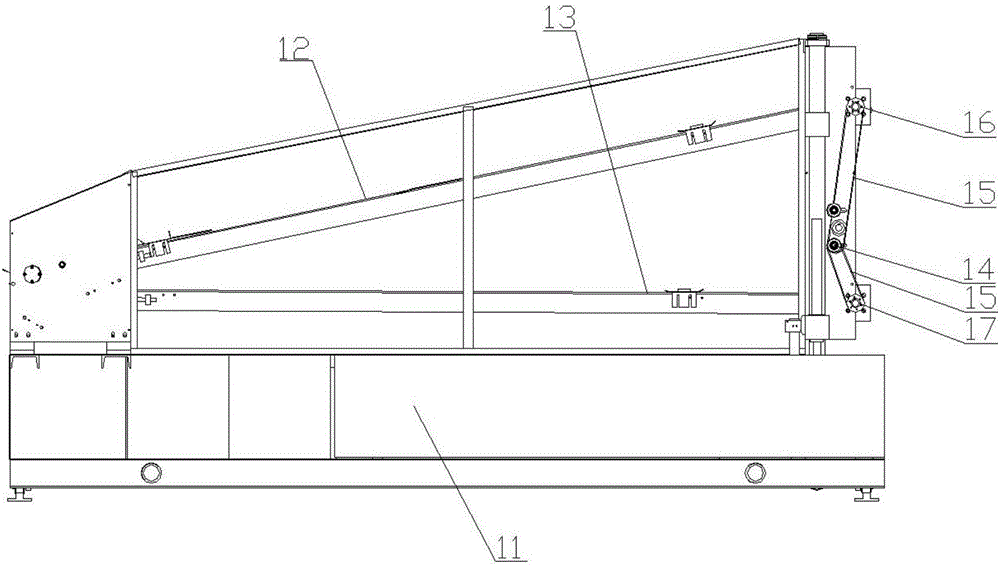

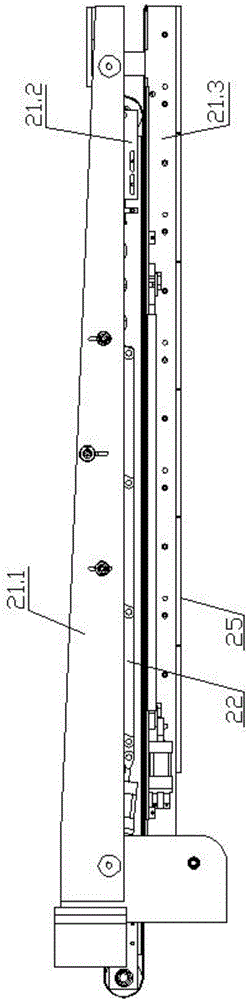

[0039] see Figure 1~Figure 17 , the present invention relates to a cross-cutting line distributing feeder, which includes a distributing device 1 connected to the discharge end of the cross-cutting line, the distributing device 1 has two discharge ends, and the two distributing devices A material sorting device 2 is respectively arranged at the discharge end;

[0040] Said material distribution device 1 comprises a material distribution device frame 11, said material distribution device frame 11 is provided with a first transverse material distribution conveyor belt 12 and a second material distribution conveyor belt 13 obliquely to the upper right, The right end of described material distribution device frame 11 is provided with material distribution power source 14, and the output end of material distribution power source 14 is respectively connected for driving the first driving wheel 16 of the first material distribution conveyor belt 12 by distribution transmission belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com