Self-cooling alcohol storage tank

A self-cooling and alcohol-based technology, applied to tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of slow cooling rate and uneven local cooling, and achieve fast cooling rate, efficient and uniform cooling, and reduce risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the embodiments.

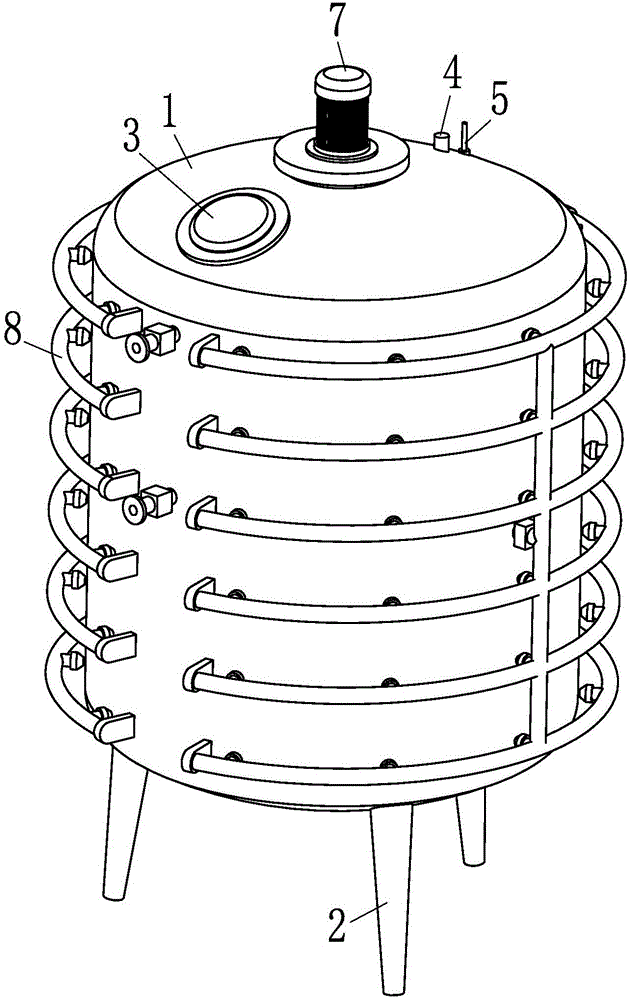

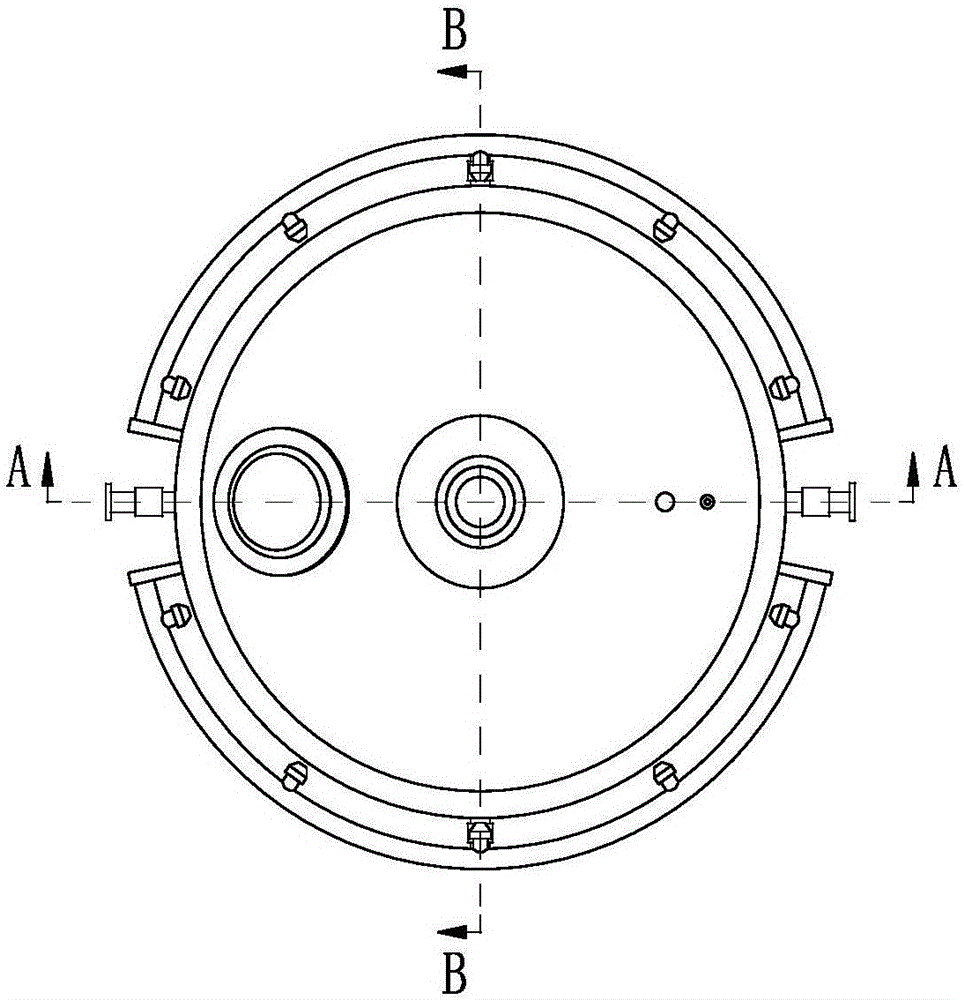

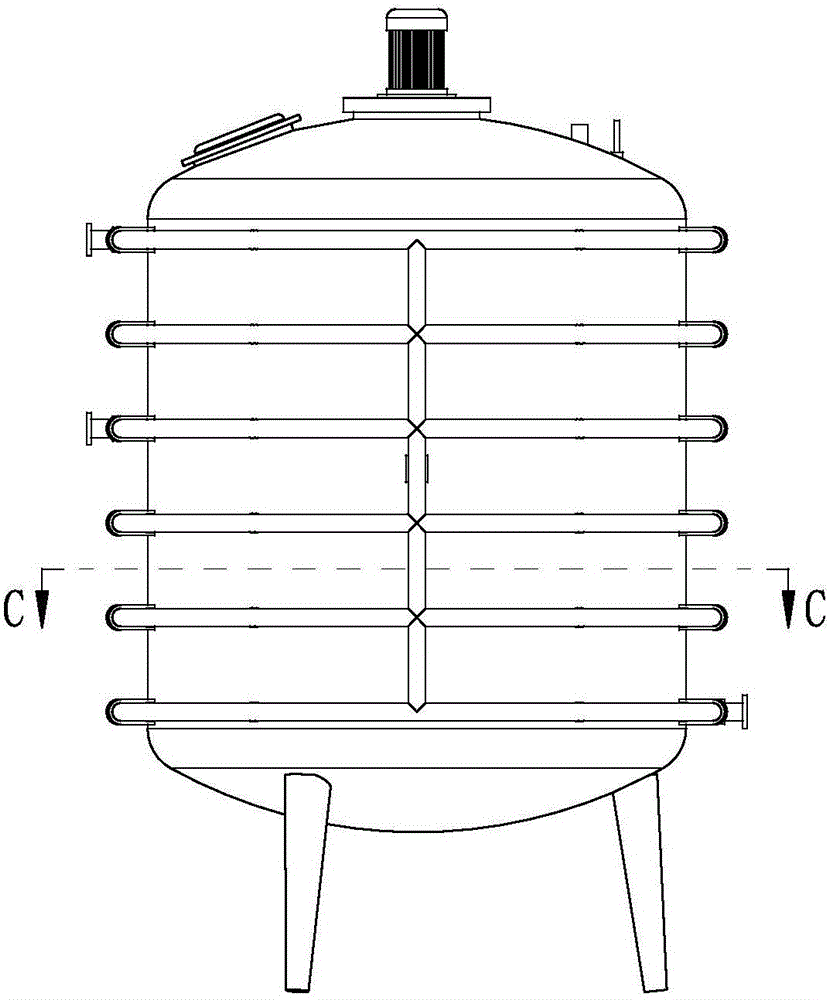

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a self-cooling alcohol storage tank according to the present invention includes a tank body 1, a leg 2, an inspection port 3 and a pressure discharge port 4, and also includes a water temperature sensor 5, an internal cooling device 6, a stirring device 7 and External cooling device 8; the stirring device 7 is located in the middle of the tank body 1, the internal cooling device 6 is wrapped around the stirring device 7, and the external cooling device 8 is wrapped around the tank body 1.

[0025] The water temperature sensor 5 is installed on the top of the tank body 1, and the water temperature sensor 5 can be used to detect the alcohol temperature in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com