Bullet-proof glass

A technology of bulletproof glass and glass, which is applied in the direction of glass/slag layered products, film/flaky adhesives, coatings, etc., which can solve the problem of low impact strength per unit of bulletproof glass, and achieve strong bulletproof ability and easy The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

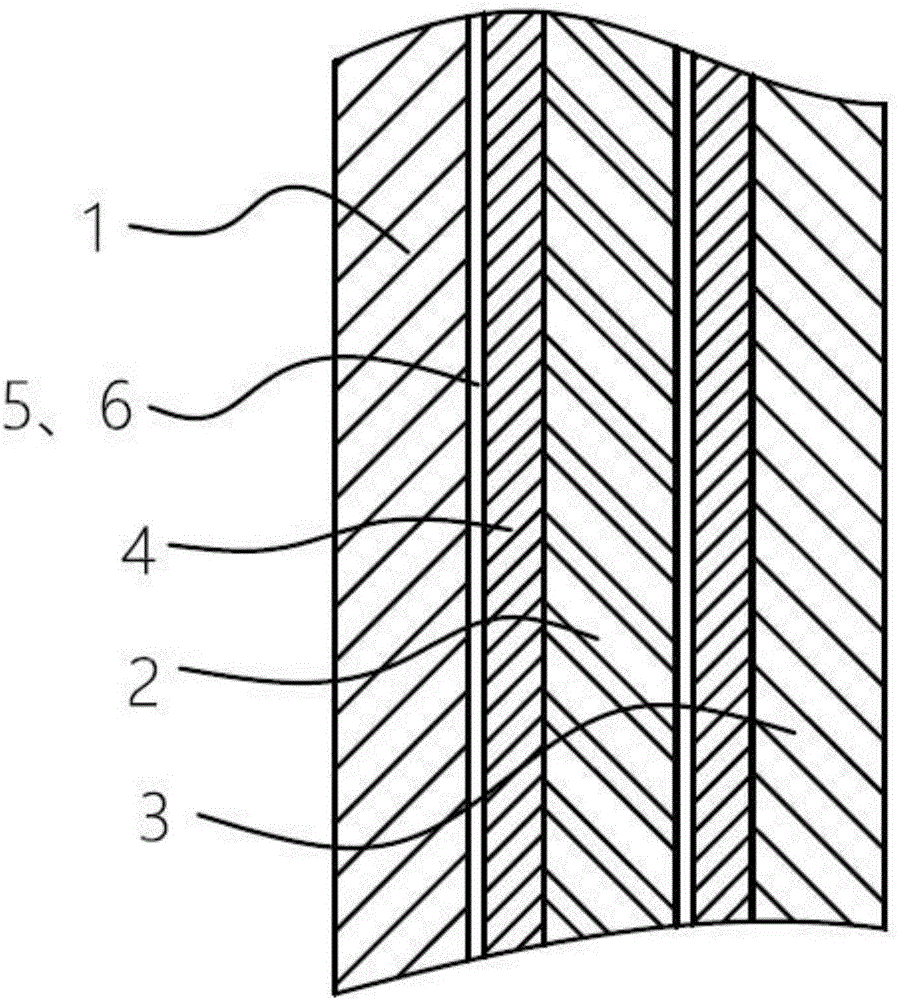

[0021] A bulletproof glass such as figure 1 As shown, it includes an inner layer of glass 1, an intermediate layer of glass 2 and an outer layer of glass 3, and a polycarbonate plate 4 is partially or completely arranged between each layer of glass, that is, at least one layer of polycarbonate plate 4 is included, each Layer glass and polycarbonate plate 4 are bonded by PVB film layer 5 or polyurethane glue layer 6, and each layer of glass is part or all of wired glass, and all of them are float glass.

[0022] The thickness of inner glass 1 is 5mm, the thickness of middle glass 2 is 4mm, the thickness of outer glass 3 is 6mm, the thickness of polycarbonate plate 4 is 2mm, the thickness of PVB film layer 5 or polyurethane adhesive layer 6 is 1mm , the thickness of the polycarbonate plate 4 is 3mm.

Embodiment 2

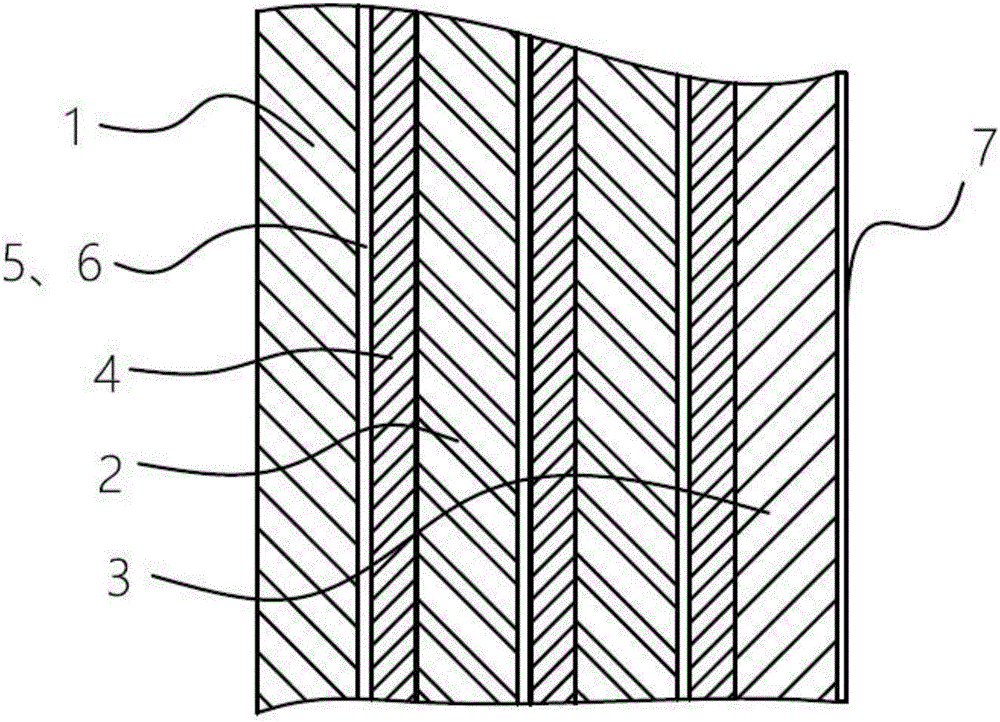

[0024] A bulletproof glass such as figure 2 As shown, it includes inner layer glass 1, two layers of intermediate layer glass 2 and outer layer glass 3, and a polycarbonate plate 4 is partially or completely arranged between each layer of glass, that is, at least one layer of polycarbonate plate 4 is included, each Layer glass and polycarbonate plate 4 are bonded by PVB film layer 5 or polyurethane glue layer 6, and each layer of glass is part or all of wired glass, and all of them are float glass.

[0025] The thickness of inner glass 1 is 6mm, the thickness of middle glass 2 is 5mm, the thickness of outer glass 3 is 4mm, the thickness of polycarbonate plate 4 is 3mm, the thickness of PVB film layer 5 or polyurethane adhesive layer 6 is 2mm , the thickness of the polycarbonate plate 4 is 2mm. A titanium dioxide film 7 is coated on the outer glass 3, and the thickness of the titanium dioxide film 7 is 0.15 μm.

Embodiment 3

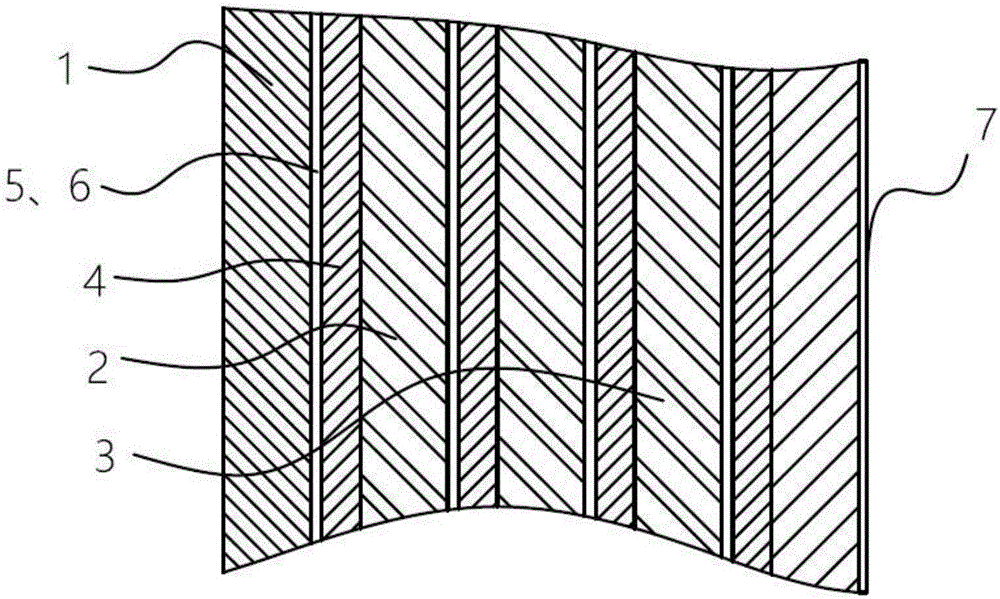

[0027] A bulletproof glass such as image 3 As shown, it includes an inner layer of glass 1, three layers of intermediate layer of glass 2 and outer layer of glass 3, and a polycarbonate plate 4 is partially or completely arranged between each layer of glass, that is, at least one layer of polycarbonate plate 4 is included, each Layer glass and polycarbonate plate 4 are bonded by PVB film layer 5 or polyurethane glue layer 6, and each layer of glass is part or all of wired glass, and all of them are float glass.

[0028] The thickness of inner glass 1 is 7mm, the thickness of middle glass 2 is 3mm, the thickness of outer glass 3 is 5mm, the thickness of polycarbonate plate 4 is 5mm, the thickness of PVB film layer 5 or polyurethane adhesive layer 6 is 0.5 mm, the thickness of the polycarbonate plate 4 is 2.3mm. The outer glass 3 is coated with a titanium dioxide film 7, and the thickness of the titanium dioxide film 7 is 0.06 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com