Method for visually identifying mold repair state based on double-CCD computer

A dual vision and mold technology, applied in the field of metal material processing, can solve the problems of short mold life, rising, and low manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

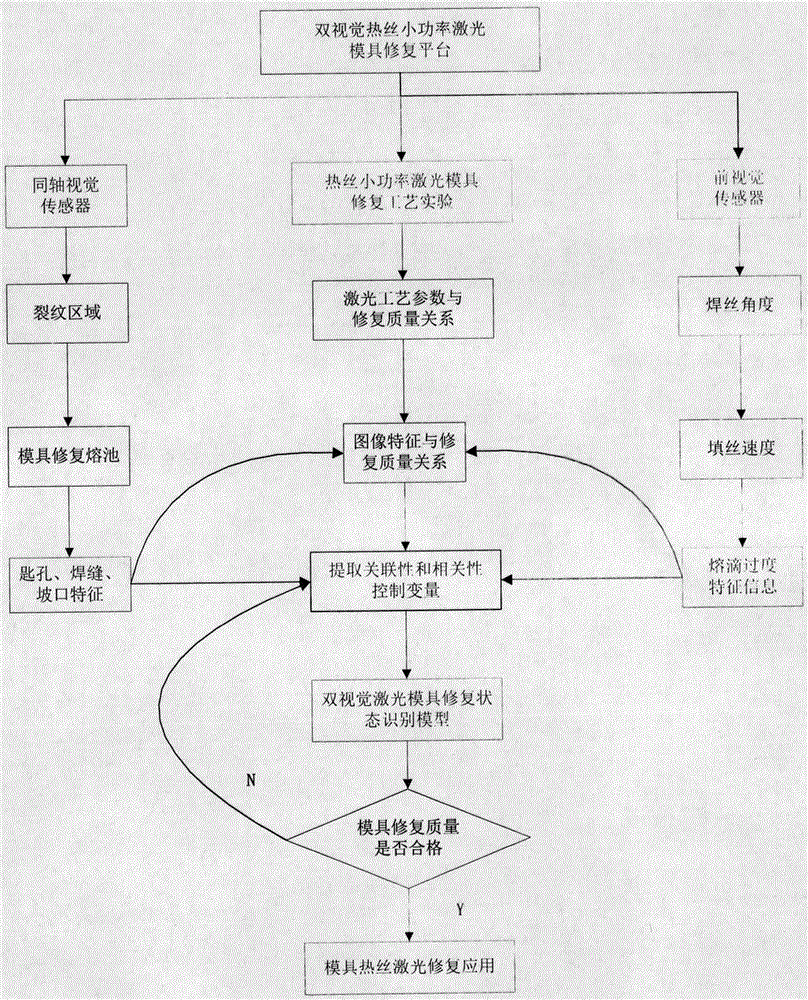

AI Technical Summary

Problems solved by technology

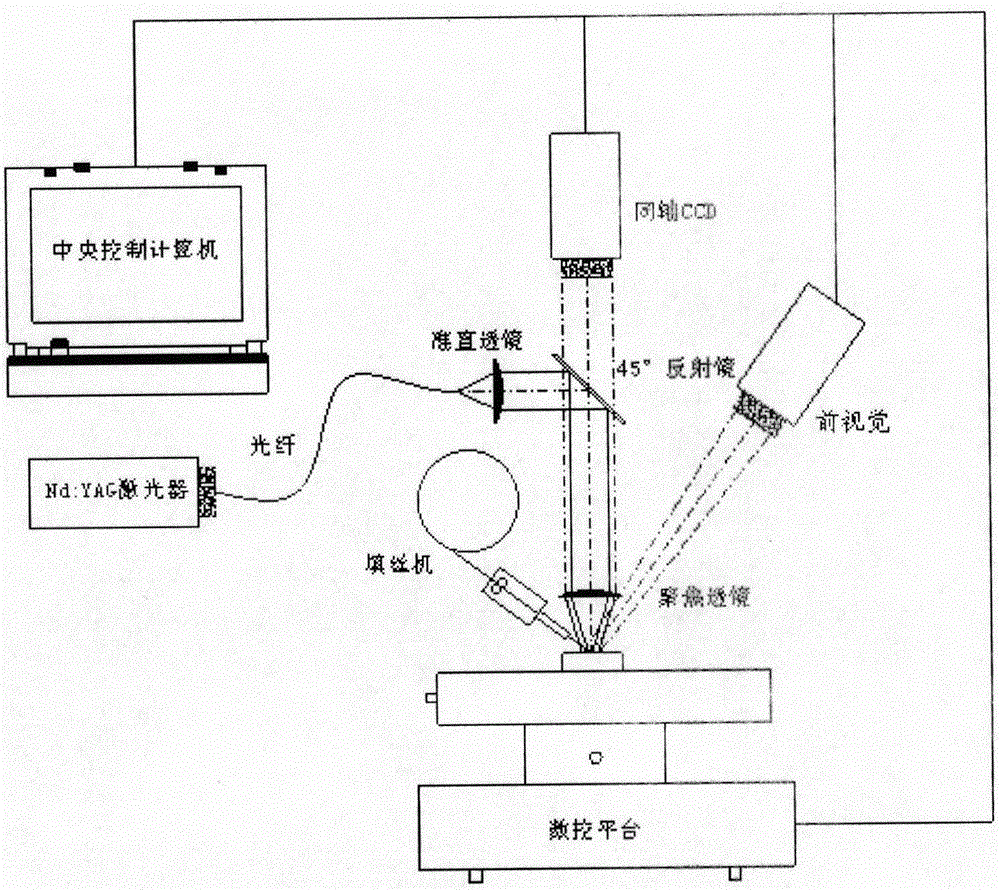

Method used

Image

Examples

example

[0018] Example: A mold repair for auto parts

[0019] Calibrate the vision system before repairing, use the developed MATLAB calibration toolbox to read the different angle images of the calibration board collected by the CCD, click "extract corner point" on the main control interface of the calibration toolbox, and determine the starting point position and X, In the direction of the Y axis, the corner points of each image are extracted. After extracting the corner points of all images in sequence, click "Calibrate" to calibrate the camera. After several iterations, the program will finally get the internal and external parameters of the camera. Import the obtained camera parameters into the computer. Use the calibrated coaxial CCD to detect the damaged mold, extract the crack image in front of the laser melting area, and perform image processing such as small window processing, filter denoising, image enhancement, morphological processing, edge extraction, and centerline ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com