Feed for metal injection molding and preparation method of feed

An injection molding and feeding technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve problems such as constraints, and achieve the effects of guaranteed use effect, high degreasing rate and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

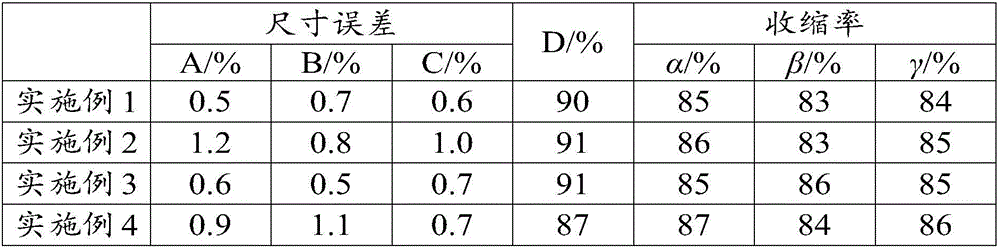

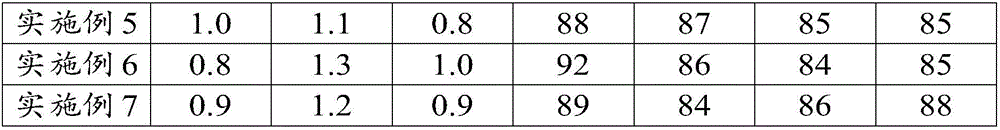

Examples

preparation example Construction

[0019] A method for preparing the feed material for metal injection molding, comprising: uniformly mixing polyoxymethylene, high molecular polymer, compatibilizer, plasticizer, surfactant and lubricant at 150-200°C to obtain a viscous Binder; then mix the binder and metal powder to make feed.

[0020] Further, in other preferred embodiments of the present invention, polyoxymethylene, high molecular polymer, and compatibilizer are uniformly mixed in a vacuum environment of 195-200°C to obtain a mixture, and the temperature is lowered to 150-160°C, and the mixture is Add plasticizer, surface active agent and lubricant to the mixture and mix uniformly to obtain binder. First mix at 195-200°C to ensure that the mixing temperature is above the melting point of each polymer component, so that the polymer components can be fully melted and mixed evenly, and then lowered to 150-160°C to add small molecule components, which can Try to avoid the destruction of small molecular component...

Embodiment 1

[0025] This embodiment provides a feedstock for metal injection molding, which is prepared by the following steps:

[0026] Add 75kg of homopolyoxymethylene, 8kg of polyethylene, and 3kg of ethylene acrylic acid copolymer into a vacuum mixer, mix evenly in a vacuum environment of 200°C to obtain a mixture, cool down to 160°C, and add 5kg of phthalic acid di Octyl esters, 0.5kg zinc stearate, and 4kg paraffin wax were mixed uniformly to obtain the binding agent.

[0027] Put 943kg of metal powder into the kneader and preheat to 160°C, add the above binder to the preheated metal powder, keep kneading at 160°C for 2 hours, extrude into strips with an extruder, and break into granules, get fed.

Embodiment 2

[0029] This embodiment provides a feedstock for metal injection molding, which is prepared by the following steps:

[0030] Add 78kg of homopolyoxymethylene, 10kg of polyethylene, and 2kg of ethylene-vinyl acetate copolymer into a vacuum mixer, mix evenly in a vacuum environment of 200°C to obtain a mixture, cool down to 160°C, and add 6kg of phthalate to the mixture Dioctyl formate, 1 kg of zinc stearate, and 1 kg of paraffin were mixed uniformly to obtain the binder.

[0031] Put 934kg of metal powder into the kneader and preheat to 160°C, add the above binder to the preheated metal powder, keep kneading at 160°C for 2 hours, extrude into strips with an extruder, and break into granules, get fed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com