Micro-pipe hydroforming device capable of axial feeding

A hydroforming and filling technology, which is applied in the field of hydroforming, can solve problems such as unreliable sealing, damage to the shape of micro-tubes, and large volume of molding equipment, and achieve the effects of precise PLC control, improved sealing performance, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

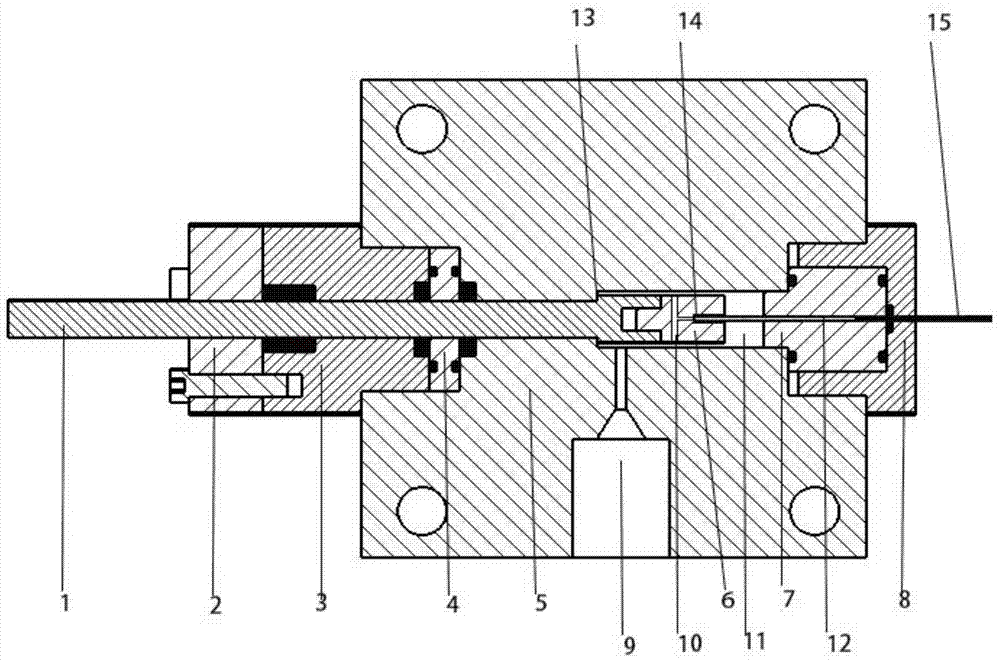

[0032] Take the processing of micro pipe fittings with an outer diameter of 2mm as an example. The material of the micro-pipe fittings used is 304 stainless steel, the outer diameter of the pipe fittings is 2mm, and the wall thickness is 0.3mm.

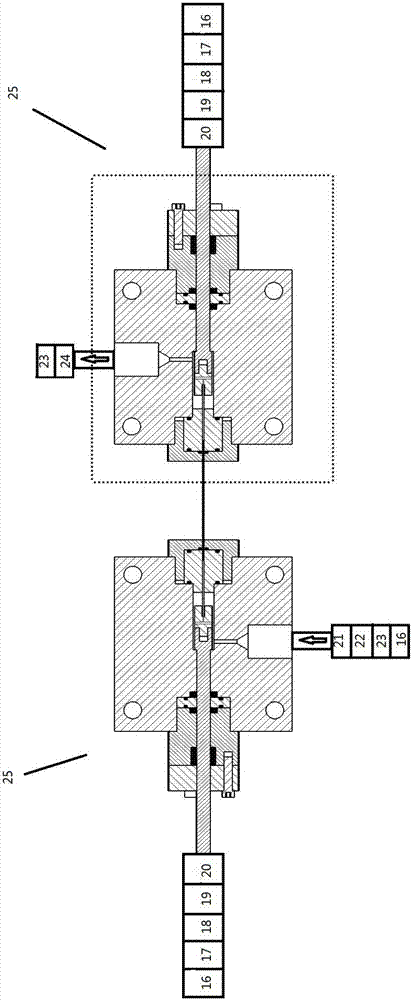

[0033] A micro-pipe hydroforming device capable of axial feeding includes two identical hydro-forming sub-devices 25, and the two hydro-forming sub-devices 25 are respectively located at both ends of the micro-pipe.

[0034] The hydroforming sub-device 25 includes a mould, an axial feeding system and an oil supply system, the oil supply system and the axial feeding system are respectively connected to the mold, and the oil supply system is connected to the axial feeding system.

[0035] As far as the mold is concerned, the volume of the connecting block 5 is 100*100*50mm, and the length direction of the entire mold is 140mm, which meets the miniaturization requirements of the microforming mold.

[0036] The mold includes a push rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com