Multistage variable-pressure pulse washing system and washing method thereof

A technology of pulse cleaning and water replenishment system, which is applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using gas flow, etc., which can solve the problems of difficult cleaning quality guarantee, high labor intensity of medical staff, and difficult cleaning quality stability and other issues, to achieve the effect of cleaning quality assurance, avoiding personnel infection, and ensuring the quality of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

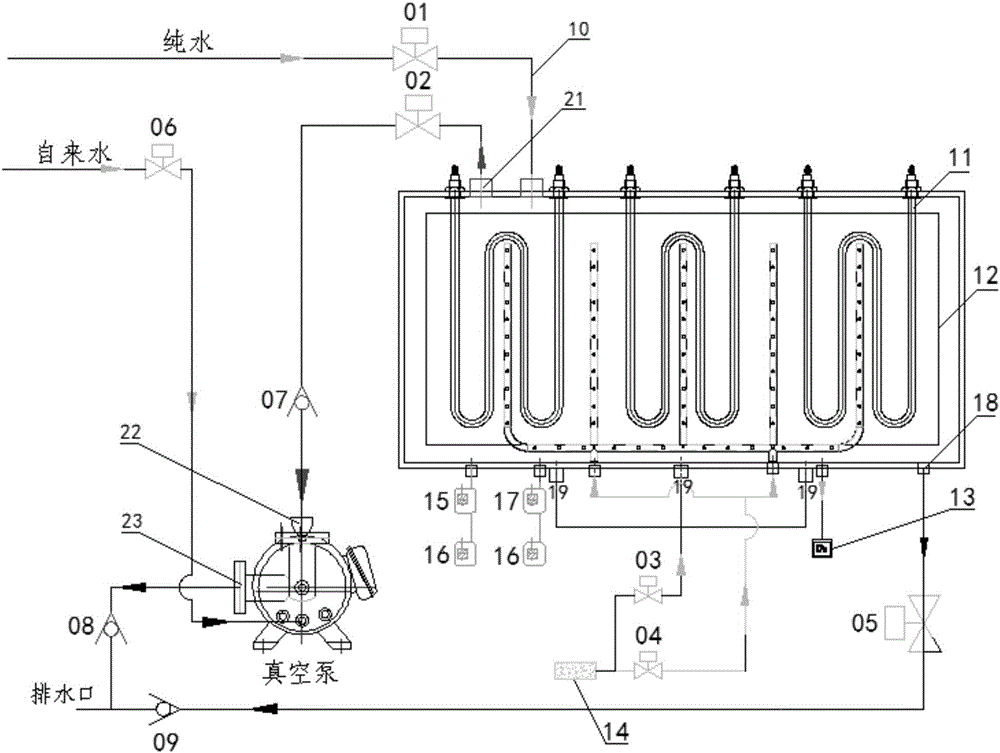

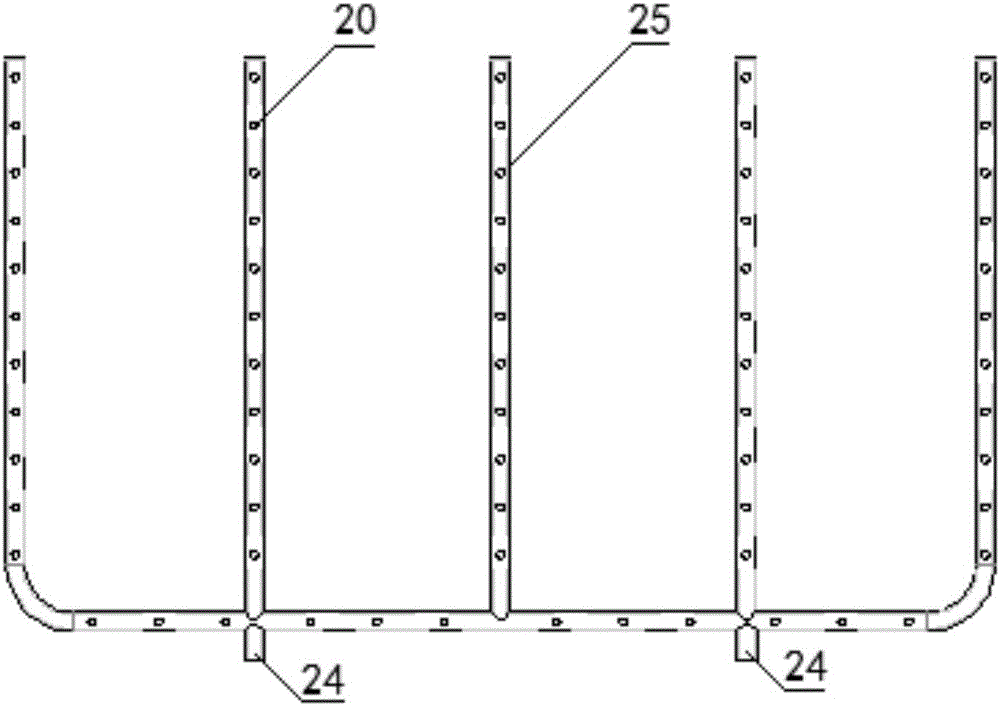

[0040] A multi-stage pressure-changing pulse cleaning system, which consists of a water supply valve 01 and connecting pipelines 10 at both ends, the inlet of the connecting pipeline is connected to an external water inlet, and the outlet is connected to a cleaning cabin; the cleaning cabin 12 consists of a cleaning tank and a tank cover Composition; M-type heating pipes 11 are evenly arranged at the bottom of the cleaning cabin 12; the detection hole of the digital display vacuum pressure gauge 13 is at the upper end of the cleaning cabin 12 and above the water level; the water inlet end of the drain pipe and the bottom of the cleaning cabin 12 The liquid outlet is connected, and the water outlet is connected with the external drain; the air-break valve 03 and the liquid-break valve 04 are connected to the filter 14 at the inlet end, and the air-break valve 03 is connected to the air-break hole 19 on the upper part of the cleaning cabin 12 , the gas outlet end of the liquid br...

Embodiment 2

[0042] A cleaning method for a multi-stage pressure-changing pulse cleaning system. For the cleaning of surgical instruments, we first put the parts to be cleaned into the cleaning cabin as required, close the cleaning cabin door, and replenish water to the cleaning cabin 12. After setting the water level, heat the cleaning liquid in the cleaning cabin, and set the temperature at 45°C to 55°C. After the temperature reaches the set temperature, turn on the vacuum valve 02 and the vacuum pump to vacuumize the cleaning cabin. During the process, the gas in the cleaning chamber is pumped out. With the gradual increase of the vacuum degree, the water in the tank gradually begins to roll and tremble. After the pressure sensor detects that the pressure reaches the set pressure and maintains it for a period of time, open the liquid The breaking valve 04X0 is closed after 0 seconds. Due to the huge pressure difference inside and outside, a large amount of air through the liquid breaking...

Embodiment 3

[0044] A cleaning method for a multi-stage pressure-changing pulse cleaning system. For the cleaning of lumen instruments, we first put the parts to be cleaned into the cleaning cabin as required, close the cleaning cabin door, and replenish water to the cleaning cabin 12. After reaching the set water level, heat the cleaning fluid in the cleaning cabin at a temperature of 45°C to 55°C. After the temperature reaches the set temperature, turn on the vacuum valve 02 and the vacuum pump to vacuumize the cleaning cabin. During the process, the air in the cleaning cabin is pumped out, and as the vacuum gradually increases, the water in the tank gradually begins to roll and tremble, and the air in the lumen device to be cleaned in the cleaning cabin is pumped out and gradually The hot steam generated in the tube cavity replaces it. After the pressure sensor detects that the pressure reaches the set pressure and maintains it for a period of time, close the vacuum valve 02, open the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com