Fluorine removing agent and preparing method thereof

A technology of defluorinating agent and exchange resin, which is applied in the field of materials, can solve the problems that the defluorinating agent cannot be industrialized, and achieve the effects of being unable to industrialize, high adsorption capacity, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

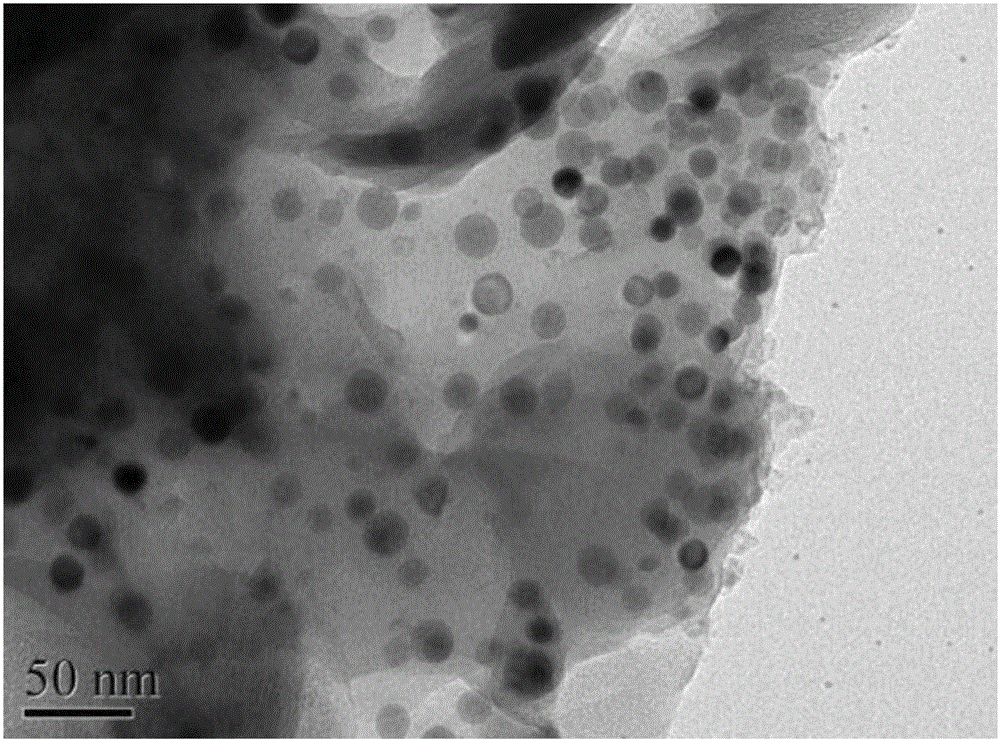

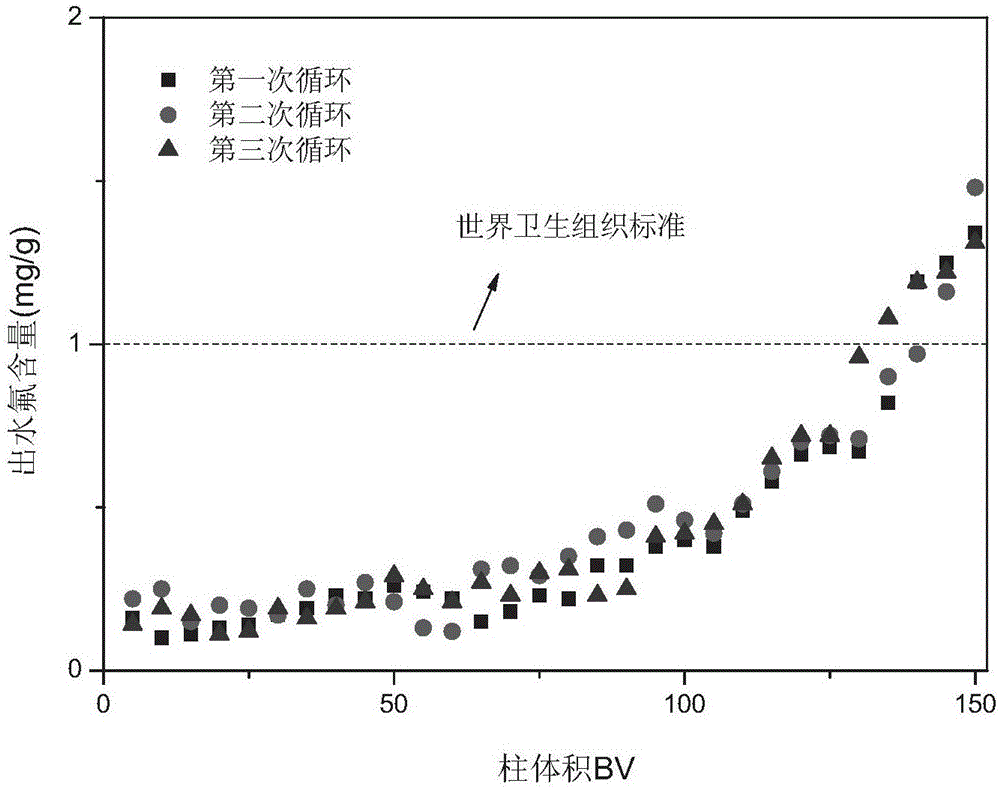

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 12g aluminum chloride, dissolve in 40ml deionized water to form a mixed solution, stir at room temperature until the solution is completely clear;

[0031] (2) Take 10g of anion exchange resin D201 and place it in an ion exchange column, rinse it with a dilute hydrochloric acid solution with a mass concentration of 5% at 0.5BV / h, rinse it with pure water until the effluent is neutral, take out D201, and put it into Soxhlet extractor, purified with ethanol, and dried in an oven at 50°C;

[0032] (3) Add the clarified solution obtained in step (1) into a reactor with a stirring and temperature control device, add 10 g of D201 pretreated in step (2), and stir for 10 h at a temperature of 45° C. in the first stage; The second stage was stirred at 60°C for 6h;

[0033] (4) Filter the solution obtained in step (3), add ammonia water, adjust the pH of the solution to 8.3, continue stirring at 60° C. for 10 h, cool, and wash with water;

[0034] (5) Add the resin obt...

Embodiment 2

[0038] (1) Take 17g aluminum chloride, dissolve in 60ml deionized water to form a mixed solution, stir at room temperature until the solution is completely clear;

[0039] (2) Take 10g of anion exchange resin D201 and place it in an ion exchange column, rinse with 5% dilute hydrochloric acid solution at a mass concentration of 0.5BV / h, rinse with pure water until the effluent is neutral, take out D201, and put it into a cable Extractor, purified with ethanol, and dried in an oven at 52°C;

[0040] (3) Add the clarified solution in step (1) to the reactor with a stirring and temperature control device, add 10 g of D201 pretreated in (2), and stir at a temperature of 45 °C for 10 h in the first stage; in the second stage Stir at 60°C for 6h;

[0041] (4) Filter the solution obtained in step (3), add ammonia water, adjust the pH of the solution to 8.5, continue to stir at 60° C. for 12 hours, cool, and wash with water;

[0042] (5) Add the resin obtained in step (4) into a lith...

Embodiment 3

[0045] (1) Take by weighing 19g aluminum chloride, dissolve in 60ml deionized water to form a mixed solution, stir at room temperature until the solution is completely clear;

[0046] (2) Take 10g of anion exchange resin D201 and place it in an ion exchange column, rinse with 5% dilute hydrochloric acid solution at a mass concentration of 0.5BV / h, rinse with pure water until the effluent is neutral, take out D201, and put it into a cable Extractor, purified with ethanol, and dried in an oven at 52°C;

[0047] (3) Add the clarified solution in step (1) to the reactor with a stirring and temperature control device, add 10 g of D201 pretreated in (2), and stir at a temperature of 50 °C for 8 hours in the first stage; in the second stage Stir at 65°C for 3h;

[0048] (4) Filter the solution in step (3), add ammonia water, adjust the pH of the solution to 8.2, continue stirring at 60° C. for 10 h, cool, and wash with water;

[0049] (5) Add the resin obtained in step (4) into a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com