After-treatment device and preparation method for hollow ultrafiltration membrane wires

A post-processing and ultrafiltration membrane technology, which is applied in ultrafiltration, thin material treatment, water/sewage treatment, etc., can solve the problem of affecting the health of operators, restricting the quality stability of membrane elements, and the amount of sealing glue can not be well controlled To achieve the effect of ensuring long-term normal operation of production, shortening the time of clamping and measurement, and reducing the difficulty of equipment improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

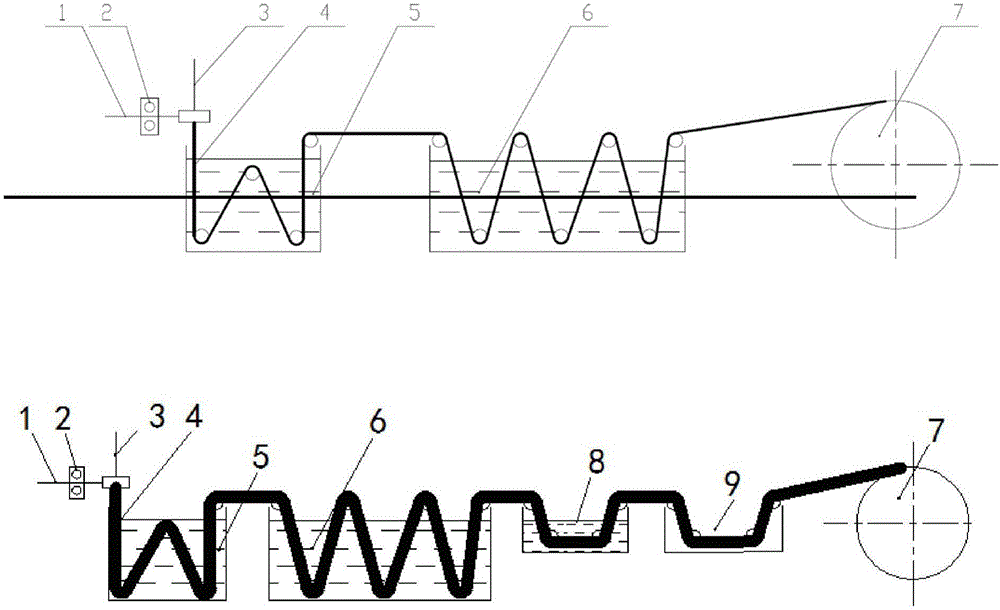

[0043] A post-processing device for hollow ultrafiltration membrane filaments, including a metering pump 2, a winding reel 7, a gel tank 5, a shaping tank 6, a positive and negative pressure cleaning tank 8 and a vacuum drying tank 9,

[0044] Such as figure 1 As shown, the spinning stock solution 1 is connected to the crochet rope 3 through the metering pump 2, and the spinning stock solution 1 becomes the RF membrane filament 4, and the RF membrane filament 4 passes through the gel tank 5, the shaping tank 6, the positive and negative pressure cleaning tank 8 and vacuum drying. Groove 9, RF film wire 4 is collected by winding reel 7,

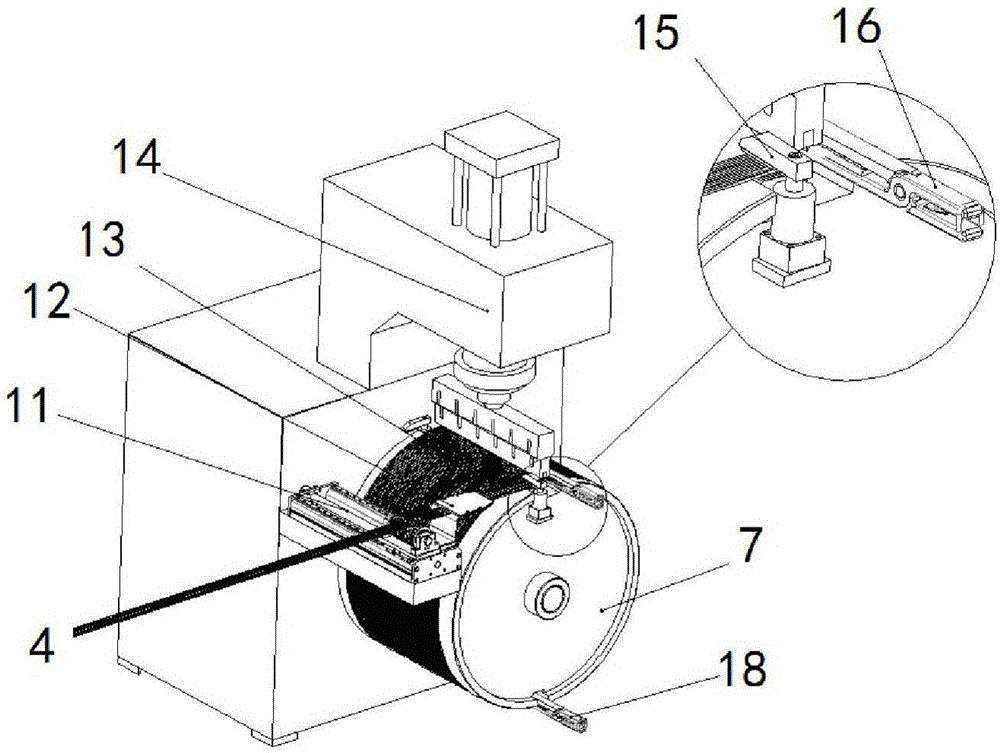

[0045] Such as figure 2 As shown, the 16 RF membrane filaments 4 are collected by the winding reel 7, the winding reel 7 is connected to the middle part to clamp the long-nosed pliers 18, the membrane filament arrangement mechanism 11 is connected to the body, and the membrane filament arrangement mechanism 11 is connected to the 16 RF membr...

Embodiment 2

[0059] Embodiment 2: The present invention relates to a post-treatment device for hollow ultrafiltration membrane filaments, which is a device that can support the preparation of membrane filaments for curtain formation in the later stage.

[0060] The invention solves the preparatory work of the hollow ultrafiltration membrane filaments in the later stage of curtain formation, improves the filtration efficiency of the membrane filaments of the water treatment equipment, improves the cleaning environment of the membrane filaments, improves the service life of the membrane filaments, and makes the appearance of the membrane filaments of the water treatment equipment beautiful. ;

[0061] A post-processing equipment for hollow ultrafiltration membrane silk: a single-axis reel type membrane silk curtain winding machine, which includes a winding drum, a screw that reciprocates synchronously with the drum, a rotary clamping cylinder, a pneumatic wire cutter, and a wire winding Mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com