Method for increasing puffing degree of apple slice and apple slice

A technology for apple chips and apple chips, which is applied to the preservation of fruits and vegetables, protection of fruits/vegetables with a protective layer, food preservation, etc. Effects of glass transition temperature, extended shelf life, increased bulking and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

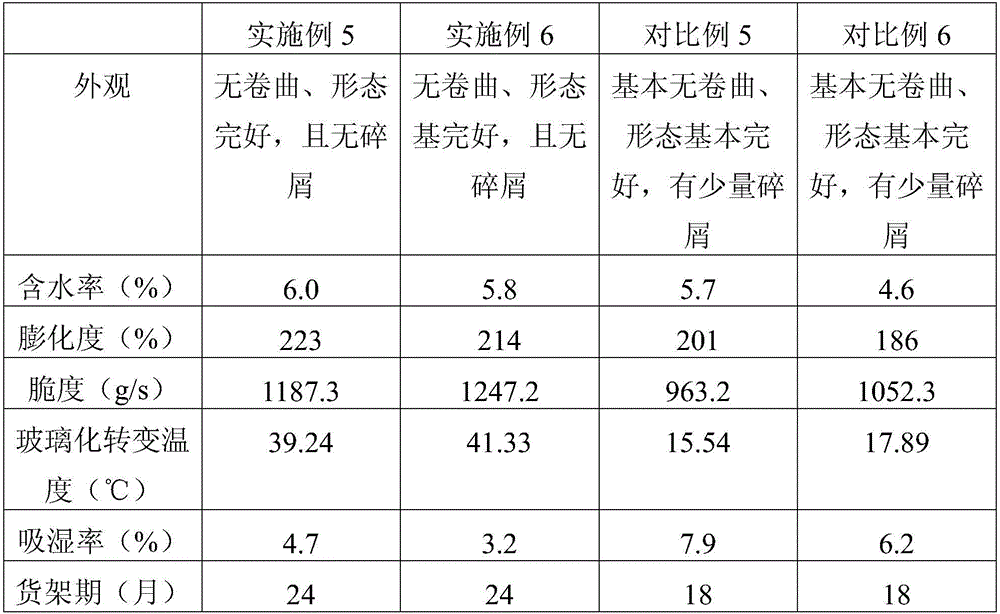

Examples

Embodiment 1

[0040] Step 1. The apples are sorted, washed, peeled and cored, and then cut into round slices with a thickness of 8mm.

[0041] Step 2, infiltration treatment: the apple slices treated in step 1 are placed in a pectin solution with a mass concentration of 4.2% for 1.5 hours under the condition of a vacuum of 6 kPa.

[0042] Step 3, pre-drying: put the pretreated apple slices in step 2 in a hot air drying oven for drying, the temperature is 70°C, the time is 250min, and the wind speed is 0.5m / s, so that the moisture content of the apple slices is 30%.

[0043] Step 4. Differential pressure puffing: put the pre-dried apple slices into the puffing tank, use steam to heat up to a puffing temperature of 110° C., the pressure reaches 0.15 MPa, and keep under this condition for 50 s. Then, open the pressure relief valve of the expansion tank, and the pressure in the expansion tank instantly drops to 0.005MPa.

[0044] Step 5. Cooling and packaging: After the puffing is over, lower ...

Embodiment 2

[0046] Except for the following parameters, other steps are the same as in Example 1.

[0047] Step 3, pre-drying: put the apple slices pretreated in step 2 in a medium and short wave infrared drying oven for drying, the wavelength is 2.7 μm, the power is 1350W, the temperature is 70°C, the time is 132min, and the wind speed is 2.1m / s .

Embodiment 3

[0049] Except for some parameters in steps 1 and 2, other steps are the same as those in Example 1.

[0050] The slice thickness of the apple slices in step 1 is 5mm. The infiltration vacuum described in step 2 was 8kPa, and the treatment was performed for 2.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com