Pichia pastoris fermentation medium for large scale production of recombinant human collagen

A technology of human collagen and fermentation medium, applied in the direction of microorganism-based methods, fermentation, microorganisms, etc., can solve the problems of high skill requirements for workers, difficult operation, and high work intensity, so as to reduce production costs and reduce energy consumption. Consumption, the effect of shortening the induction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

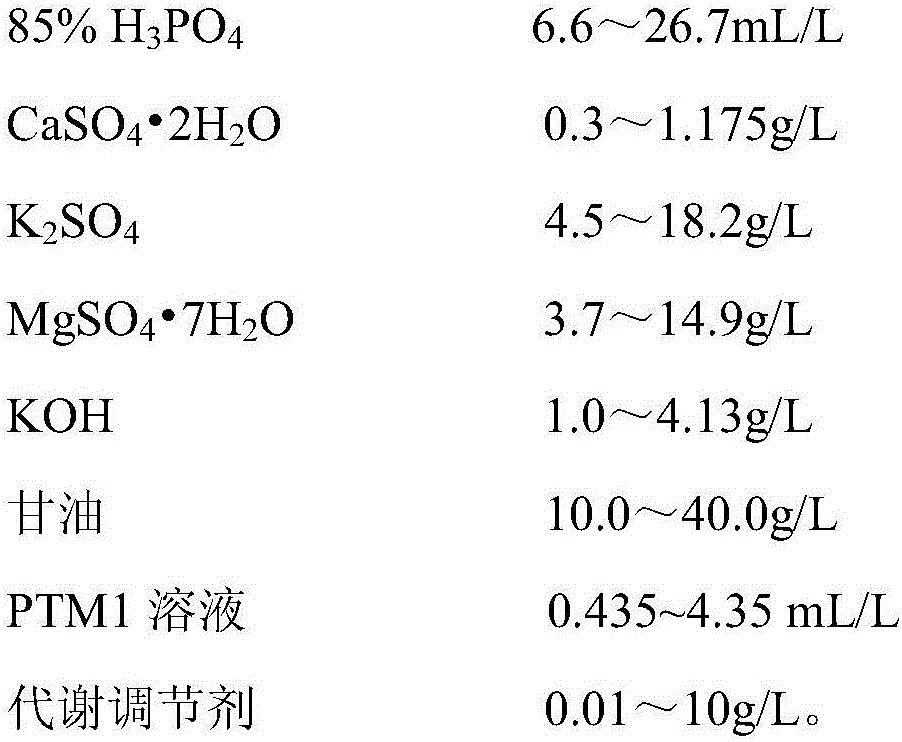

[0019] Fermentation medium: 85% H 3 PO 4 26.7mL / L; CaSO 4 2H 2 O 1.175g / L; K 2 SO 4 18.2g / L; MgSO 4 ·7H 2 O 14.9g / L; KOH 4.13g / L; glycerin 40.0g / L; PTM1 4.35mL / L; pyruvate 0.01g / L.

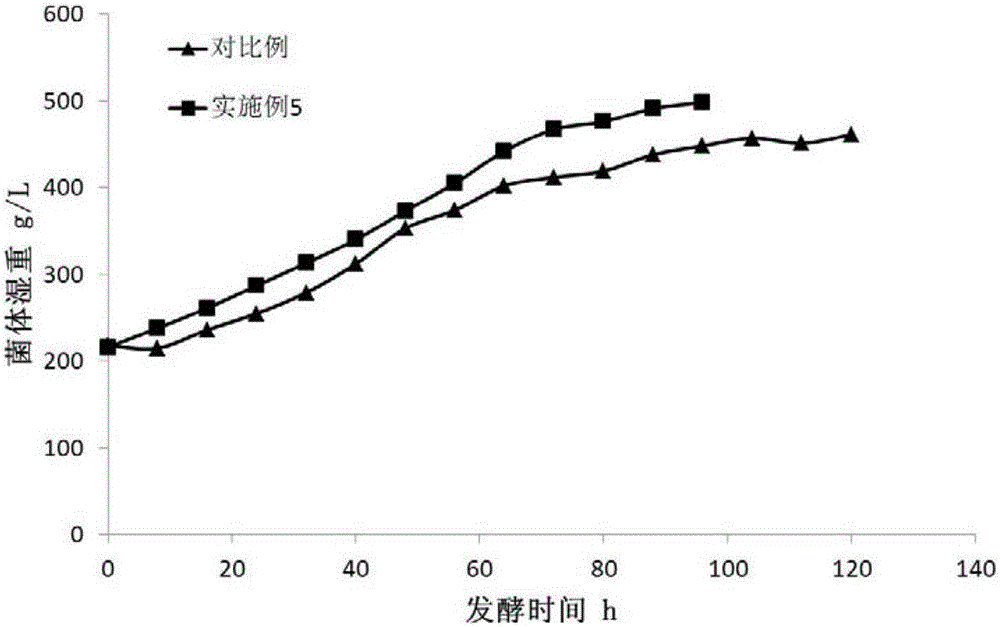

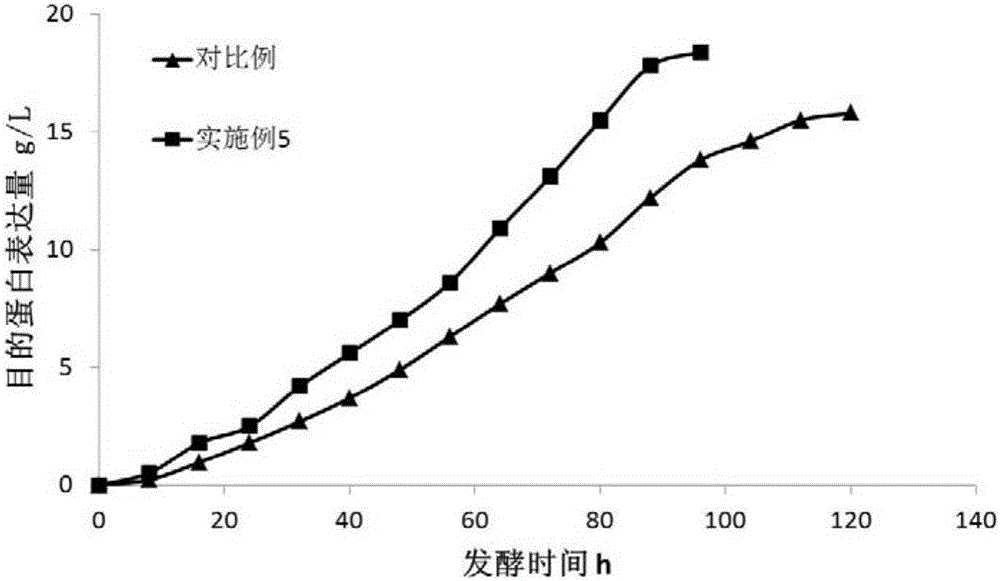

[0020] Add the seed solution to a 1000L fermenter containing 500L fermentation medium according to 10% inoculation amount, adjust the stirring speed to 200-600rpm, the tank pressure to 0.2-1.0bar, and adjust the air flow to make dissolved oxygen (DO) > 30%. When the carbon source was exhausted, the dissolved oxygen rose sharply, and 50% glycerin was added to replenish the carbon source until the wet weight of the bacteria was 215g / L, and the 50% glycerol was stopped. After the glycerol is exhausted, add methanol as a new carbon source, enter the methanol induction culture stage, and adjust the rotation speed, tank pressure, air flow, and methanol feeding speed to make the dissolved oxygen (DO) > 20%, and take samples every 8 hours , measure the wet weight of the bacteria and the expressi...

Embodiment 2

[0022] Fermentation medium: 85% H 3 PO 4 26.7mL / L; CaSO 4 2H 2 O 1.175g / L; K 2 SO 4 18.2g / L; MgSO 4 ·7H 2 O 14.9g / L; KOH 4.13g / L; glycerin 40.0g / L; PTM1 4.35mL / L; pyruvate 10g / L.

[0023] Add the seed solution to a 1000L fermenter containing 500L fermentation medium according to 10% inoculation amount, adjust the stirring speed to 200-600rpm, the tank pressure to 0.2-1.0bar, and adjust the air flow to make dissolved oxygen (DO) > 30%. When the carbon source was exhausted, the dissolved oxygen rose sharply, and 50% glycerol was added to supplement the carbon source until the wet weight of the bacteria was 216g / L, and the 50% glycerol was stopped. After the glycerol is exhausted, add methanol as a new carbon source, enter the methanol induction culture stage, and adjust the rotation speed, tank pressure, air flow, and methanol feeding speed to make the dissolved oxygen (DO) > 20%, and take samples every 8 hours , measure the wet weight of the bacteria and the expressio...

Embodiment 3

[0025] Fermentation medium: 85% H 3 PO 4 26.7mL / L; CaSO 4 2H 2 O 1.175g / L; K 2 SO 4 18.2g / L; MgSO 4 ·7H 2 O 14.9g / L; KOH 4.13g / L; glycerin 40.0g / L; PTM1 4.35mL / L; pyruvate 0.1g / L.

[0026] Add the seed solution to a 1000L fermenter containing 500L fermentation medium according to 10% inoculation amount, adjust the stirring speed to 200-600rpm, the tank pressure to 0.2-1.0bar, and adjust the air flow to make dissolved oxygen (DO) > 30%. When the carbon source was exhausted, the dissolved oxygen rose sharply, and 50% glycerol was started to supplement the carbon source until the wet weight of the bacteria was 218g / L, and the 50% glycerol was stopped. After the glycerol is exhausted, add methanol as a new carbon source, enter the methanol induction culture stage, and adjust the rotation speed, tank pressure, air flow, and methanol feeding speed to make the dissolved oxygen (DO) > 20%, and take samples every 8 hours , measure the wet weight of the bacteria and the expres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com