Positive electrode active material for non-aqueous electrolyte secondary battery and method for producing same, and non-aqueous electrolyte secondary battery manufactured using said positive electrode active material

A positive electrode active material and secondary battery technology, applied in the direction of active material electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of not getting lithium-nickel composite oxide positive electrode active materials, etc., and achieve the improvement of lithium ion conductivity and increase Battery capacity and the effect of maintaining battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

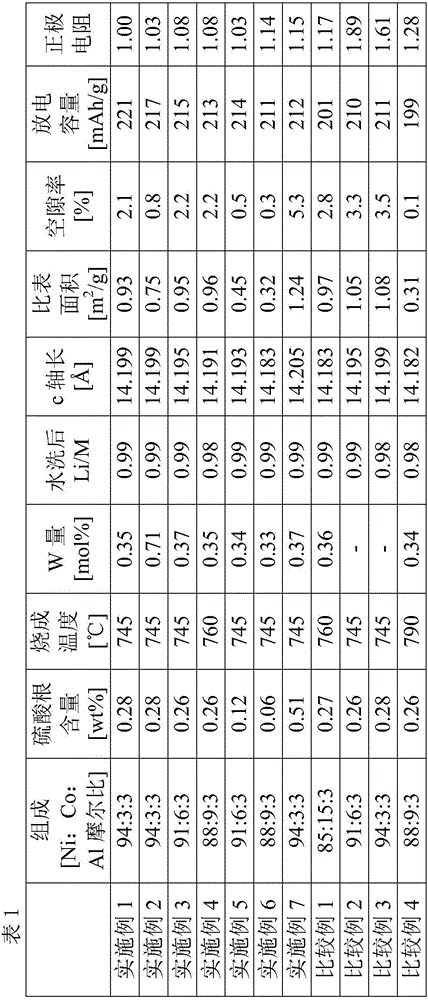

[0364] First, the temperature in the reaction tank is set to 49.5°C, and the reaction solution in the reaction tank is maintained at a pH value of 13.0 based on a liquid temperature of 25°C using 20% by mass of sodium hydroxide solution. A mixed aqueous solution of nickel sulfate and cobalt sulfate, an aqueous solution of sodium aluminate, and 25% by mass of ammonia water were added to the mixture, and recovered by overflowing. Further, after washing with a 45 g / L sodium hydroxide aqueous solution with a pH value of 12.5 based on a liquid temperature of 25° C., washing with water and drying, the nickel composite hydroxide (neutralized crystallization method).

[0365] The nickel composite hydroxide is composed of spherical secondary particles formed by agglomeration of a plurality of primary particles of 1 μm or less. According to the analysis by the ICP method, it was confirmed that the molar ratio of Ni:Co:Al was 94: 3:3 nickel composite hydroxide.

[0366] The nickel co...

Embodiment 2

[0385] A positive electrode active material was obtained and evaluated in the same manner as in Example 1, except that the alkaline solution (W) was passed through water and the water content of the dehydrated filter cake was controlled to 12.0%. The results are shown in Table 1.

Embodiment 3

[0387] Except having crystallized so that the molar ratio of Ni:Co:Al might become 91:6:3 as a nickel composite hydroxide, it carried out similarly to Example 1, and obtained the positive electrode active material, and evaluated it. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com