Microchannel liquid cooling heat radiator and conduction cool plug for high heat flux chip

A high heat flux density, micro-channel technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of rising heating power, reduce contact thermal resistance, facilitate heat dissipation, and improve heat exchange efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as figure 1 As shown, a micro-channel liquid cooling heat sink for high heat flux density chips of this embodiment is fixedly mounted on one side of the chip 3; it includes a chip packaging board 1, a cover plate 2 and a cooling liquid circulation device. The chip packaging board 1 is packaged and fixed on one side of the chip 3, the edge of the other side of the chip packaging board 1 and the edge of the cover plate 2 are sealed and fixedly connected, the chip packaging board 1 and the cover A circulation cavity is formed between the plates 2, the chip packaging board 1 is provided with a plurality of heat dissipation teeth 11 on one side of the circulation cavity; the cover plate 2 is provided with a liquid inlet 21 and a liquid outlet 22 The liquid inlet hole 21 and the liquid outlet hole 22 are respectively communicated with the cooling liquid circulation device through a liquid cooling pipe 8. The liquid cooling pipe in this embodiment is a semi-rigid water pip...

Embodiment 2

[0040] A conductive cooling plug-in of this embodiment includes a plug-in body and the micro-channel liquid cooling heat sink as described in Embodiment 1. The chip packaging board 1, the cover plate 2 and the chip 3 are all fixed inside the plug-in body, The cooling liquid circulation device is located outside the plug body. The conductive cold insert in this embodiment is a VPX conductive cold insert.

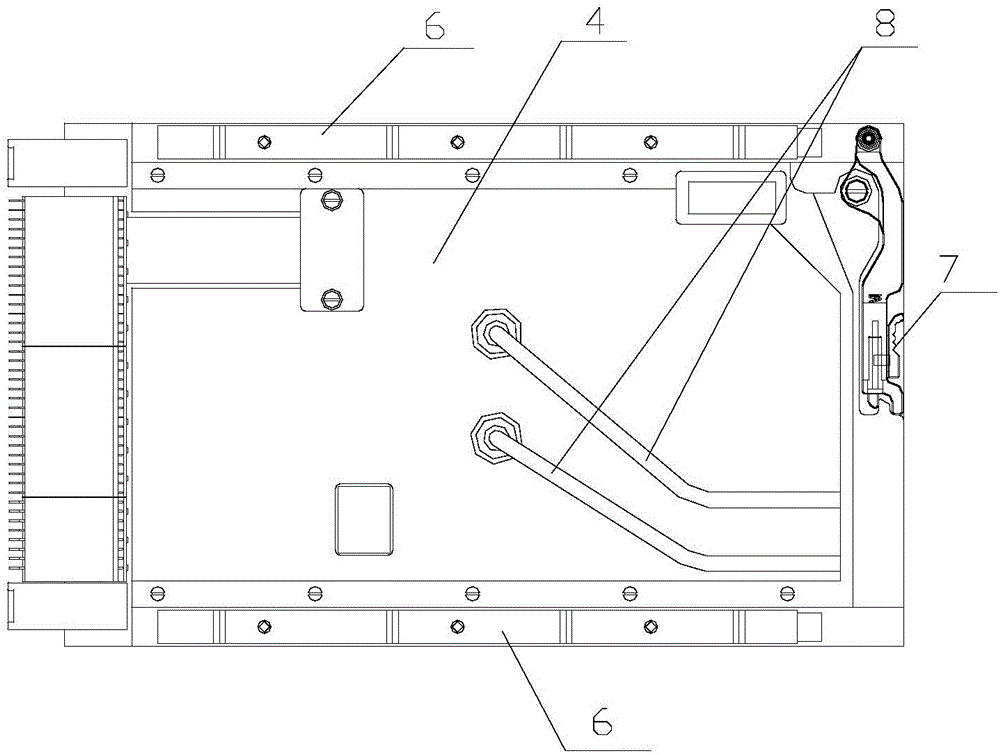

[0041] Such as figure 2 with image 3 As shown, the plug-in body of this embodiment includes a plug-in cold plate 4 and a printed board 5. The plug-in cold plate 4 is fixedly connected to the printed board 5 by screws, and the micro-channel liquid cooling radiator is fixed on Between the plug-in cold plate 4 and the printed circuit board 5. A wedge-shaped locking device 6 is provided on the outer edge of the plug-in cold plate 4, a handle 7 is provided at one end of the plug-in cold plate 4, and the plug-in cold plate 4 is locked and fixed to the chassis by the wedge-shaped l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com