Tunable frequency type signal processing system for aluminum electrolysis anode current measuring instrument

A technology of current measuring instrument and aluminum electrolytic anode, which is applied in the field of aluminum electrolysis, can solve problems such as inaccurate signal processing, and achieve the effects of improving accuracy and stability, signal stability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

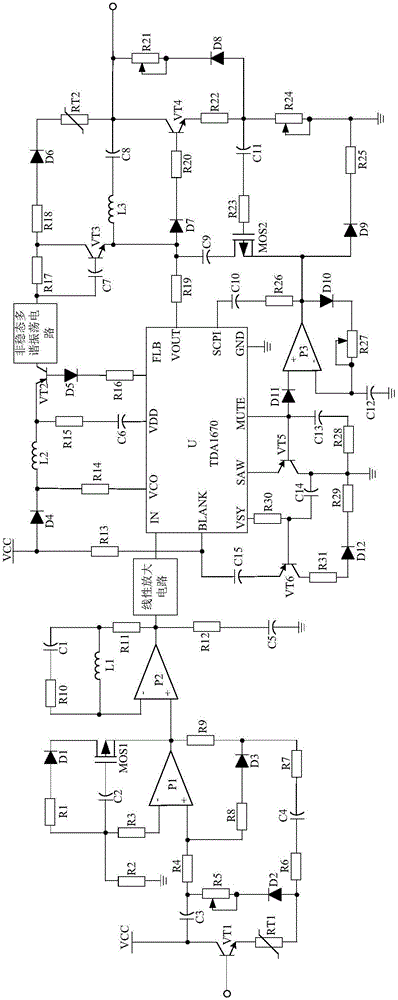

[0023] like figure 1 As shown, the present invention is mainly composed of a processing chip U, a transistor VT2, a diode D4 whose P pole is connected to the BLANK pin of the processing chip U through a resistor R13, and the N pole is connected to the VCO pin of the processing chip U through a resistor R14. , one end is connected to the N pole of the diode D4, the other end is connected to the emitter of the transistor VT2, the positive pole is connected to the emitter of the transistor VT2 through the resistor R15, and the negative pole is connected to the VDD pin of the processing chip U. The polar capacitor C6, the P pole is connected to the base of the transistor VT2, the N pole is connected to the FLB pin of the processing chip U through the resistor R16, and the diode D5 is connected to the IN pin of the processing chip U. Linear amplification circuit, a signal receiving filter circuit connected with the linear amplifier circuit, a signal frequency compensation circuit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com