Sintering method of high-titanium vanadium-titanium magnetite concentrates

A vanadium-titanium-magnetite concentrate and sintering method technology, which is applied in the field of iron ore sintering, can solve the problems of poor sintering performance of high-titanium-type vanadium-titanium magnetite concentrate, etc., and achieves the benefits of sintering performance, improving oxygen potential, and improving sintering utilization coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

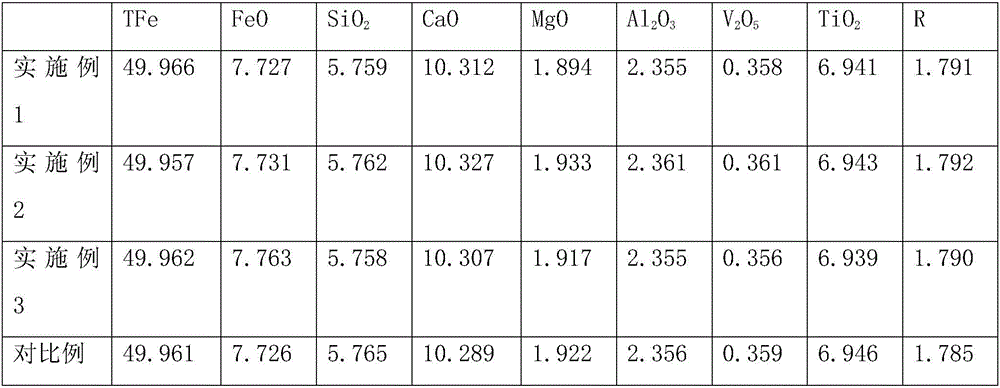

[0038] Embodiment 1 is that 70kg of sintering fresh material adds its weight 0.5wt% potassium permanganate aqueous solution, adds its weight 30wt% back to ore and carries out sintering; Embodiment 2 is sintering new material 70kg and its weight 1wt% permanganate Potassium aqueous solution, add the return ore of its weight 30wt% again and carry out sintering; Embodiment 3 adds the potassium permanganate aqueous solution of its weight 2wt% for sintering new material 70kg, adds the return ore of its weight 30wt% again and carries out sintering; Comparative example is Add 70kg of sintered fresh material plus its weight of 30wt% return ore for sintering.

[0039] Mix the raw materials in the examples and comparative examples, the first mixing time is 8 minutes, the second mixing time is 4 minutes, and the moisture content of the sintered material after control mixing is: Example 1 7.4%, Example 2 7.5%, Example 3 7.5% , 7.4% for the comparative example; see Table 1 below for the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com