Fubang oxygen-enriched side-blown bath copper smelting furnace and operation method thereof

A technology for copper smelting furnaces and smelting furnaces, applied in furnaces, electric furnaces, rotary drum furnaces, etc., which can solve the problems of polluting the surrounding air environment of enterprises, adverse effects on human and biological survival, and large equipment footprint, so as to avoid unsatisfactory operation Effects of stability, saving material consumption, and copper content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

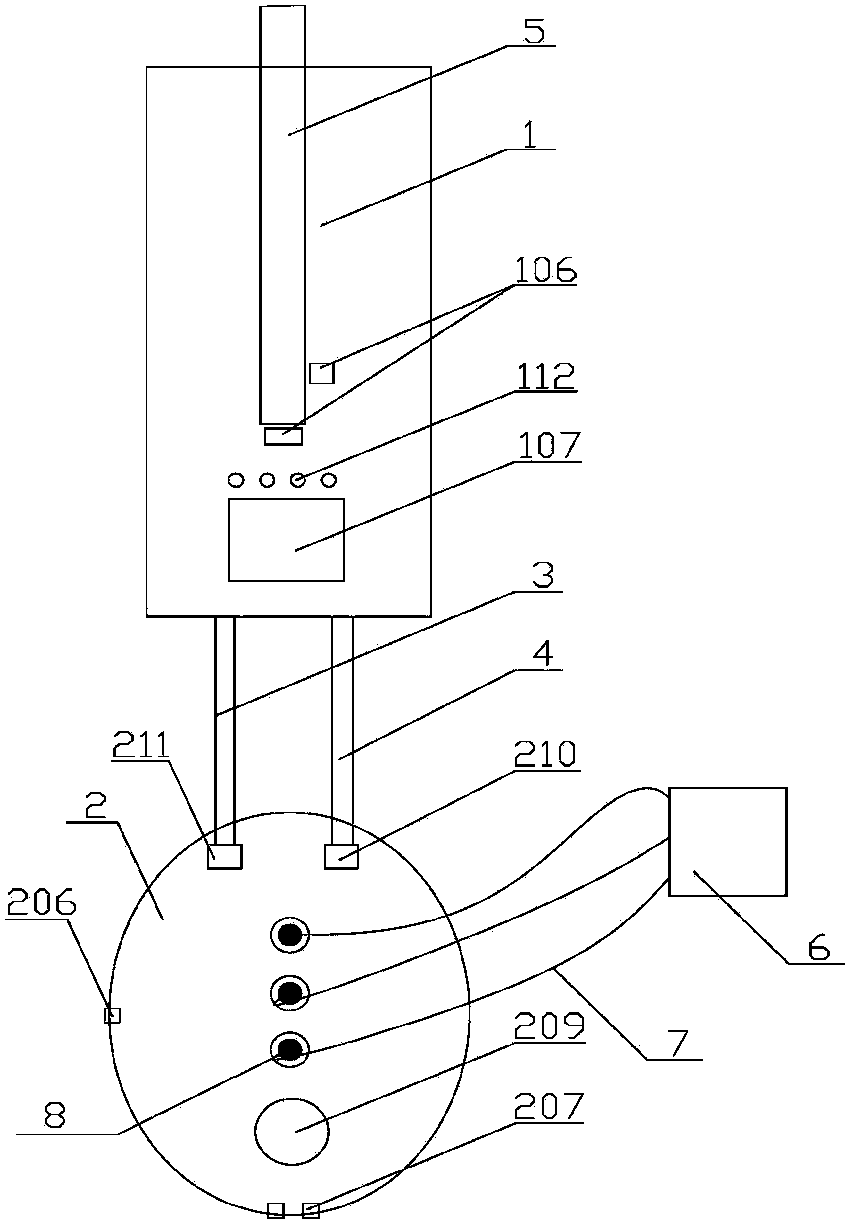

[0034] refer to figure 1 As shown, the oxygen-enriched side-blowing molten pool copper smelting device designed in this invention consists of a smelting furnace (1), a heat preservation electric furnace (2), a matte chute (3), a smelting slag chute (4), and a feeding belt (5) , transformer (6), copper busbar (7) and electrode (8), wherein the matte chute (3) and the slag chute (4) respectively connect the smelting furnace (1) and the heat preservation electric furnace (2) into a whole, The feeding belt (5) transports the charge to the feeding port (106) of the melting furnace, the input end of the transformer (6) is connected to the external power grid, and its output end is connected to the electrode (8) through the copper busbar (7), and the electrode (8) is inserted into the In the furnace of the heat preservation electric furnace (2).

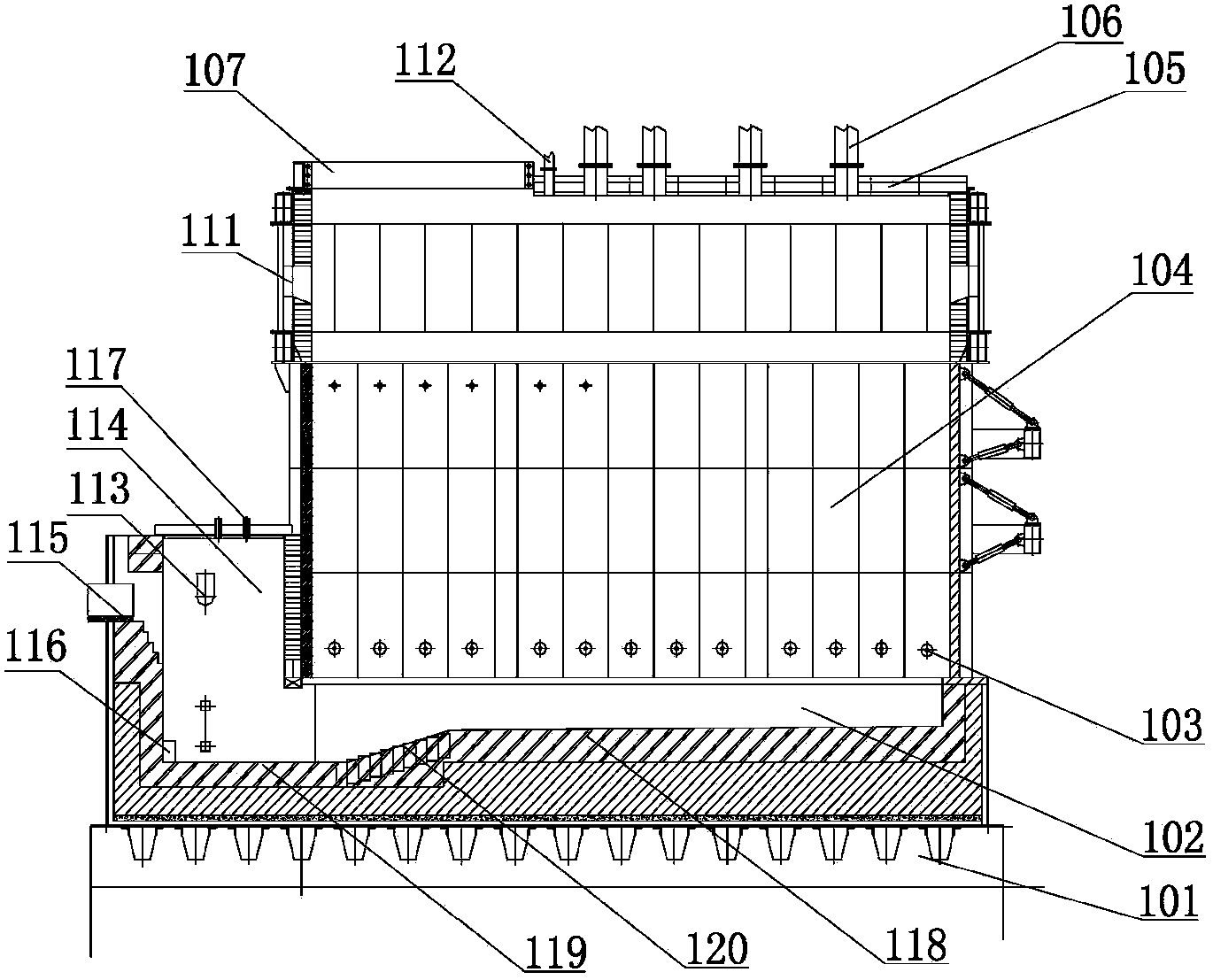

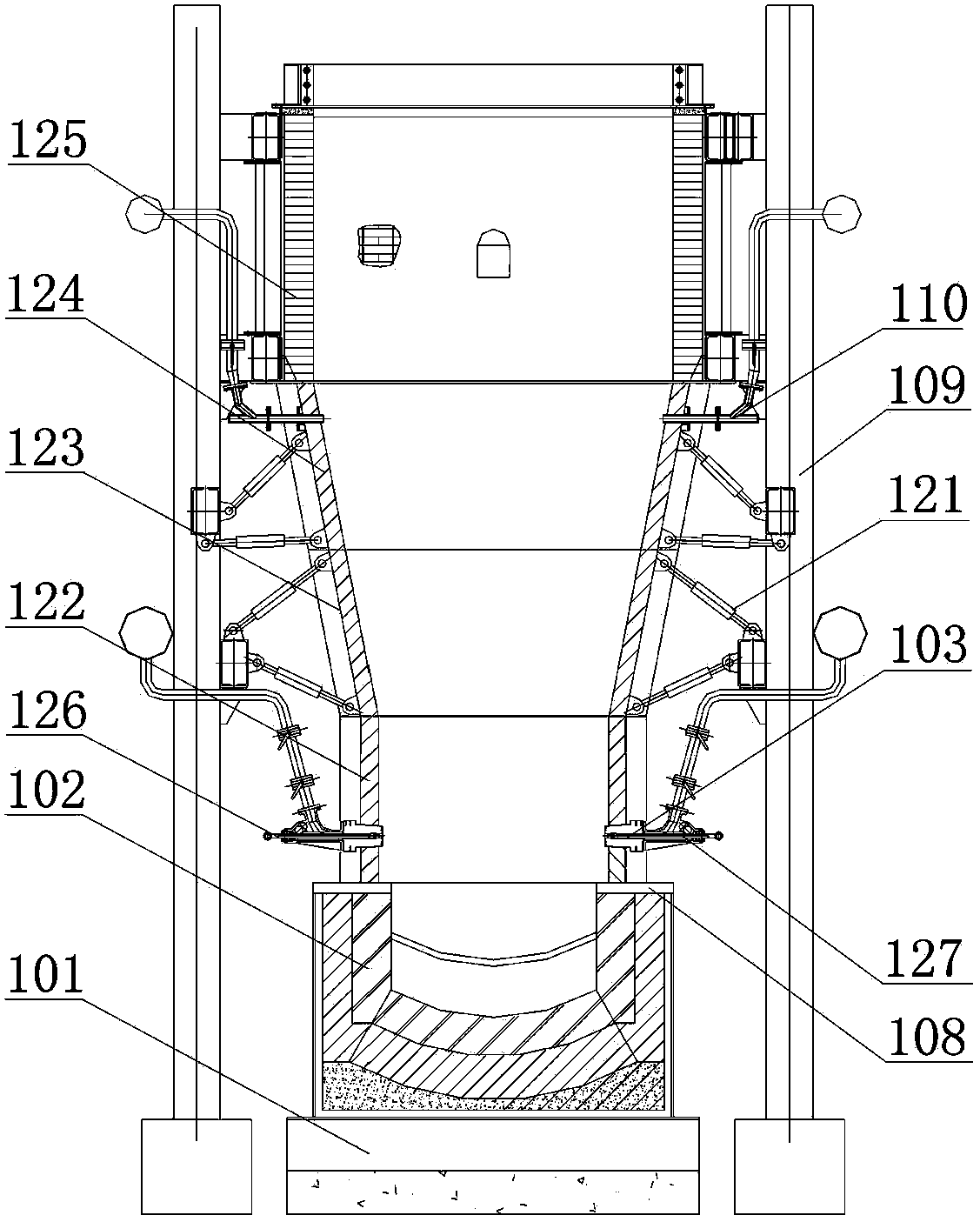

[0035] refer to figure 2 , image 3 As shown, the smelting furnace is mainly composed of a smelting furnace foundation (101), a furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com