Movable foam metal based phase-change energy-storage temperature control system and method thereof

A foam metal, temperature control system technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problem of system heat storage capacity loss and other problems, and achieve the effects of convenient operation, high device flexibility, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

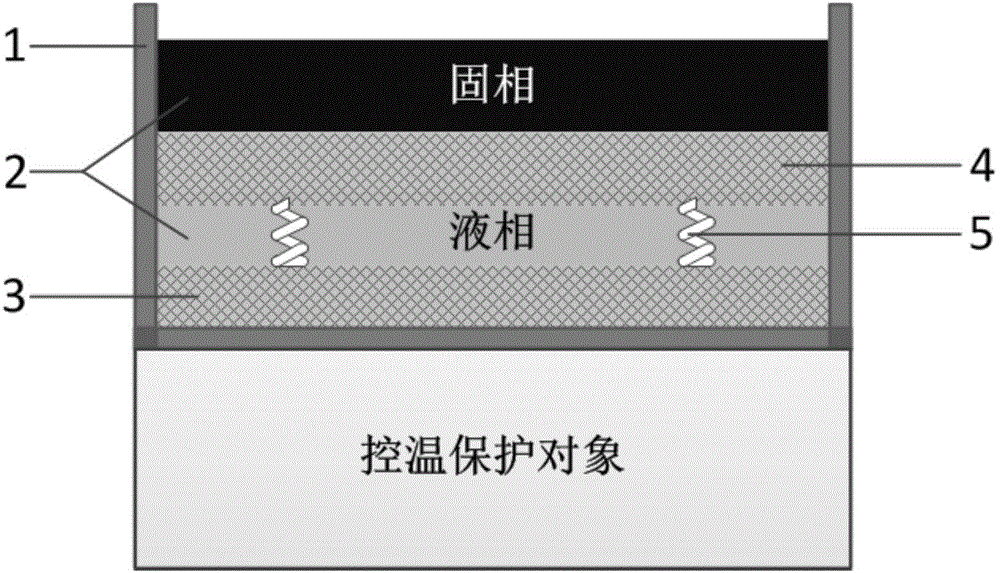

[0026] Such as figure 1 As shown, the phase change energy storage temperature control system based on mobile metal foam includes cavity 1, phase change material 2, fixed metal foam skeleton 3, mobile metal foam skeleton 4 and memory alloy 5; cavity 1 is filled with phase change material 2. The fixed metal foam skeleton 3 is fixed on the side of the cavity close to the temperature control protection object, the mobile metal foam skeleton 4 is adjacent to the fixed metal foam skeleton 3, and the mobile metal foam skeleton 4 is filled in the phase change material 2, and the metal foam is fixed The skeleton 3 is connected with the mobile metal foam skeleton 4 through the memory alloy 5, and the expansion and contraction of the memory alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com