Modified nanometer composite polysulfide sealing glue for fireproof glass

A technology of polysulfide sealant and fireproof glass, applied in the field of sealant, can solve the problems of reduced adhesion and air tightness of fireproof glass, fire prevention of fireproof glass, failure of heat insulation, and bubbles of fireproof material of fireproof glass layer, etc. Reduction of airtightness and mechanical strength, protection of thermal insulation, effect of increasing airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

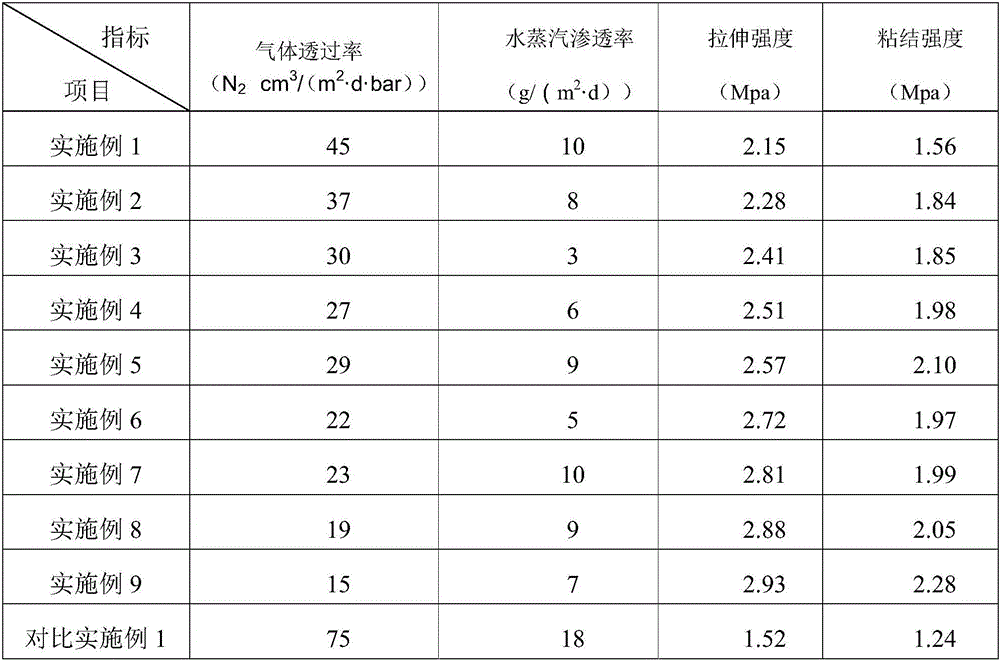

Examples

Embodiment 1

[0033] Step 1) Modification of nano-powder: select white graphene with 1-10 layers, soak for 24 hours with 0.1% oleylamine aqueous solution, obtain white graphene modified powder after centrifugation and vacuum drying;

[0034] Step 2) Preparation of base rubber components: Weigh 100 parts of liquid polysulfide rubber and 1 part of silane coupling agent in turn according to parts by weight, add them to the mixer, mix and stir for 5 minutes, and then add 0.1 parts of step 1) preparation in sequence The modified white graphene powder and 30 parts of nano-silicon dioxide were mixed for 45 minutes at a mixing temperature of 40°C. After the components were mixed and stirred evenly, they were repeatedly ground by a three-roller mill three times to obtain the base rubber component. .

[0035] Step 3) Preparation of vulcanization components: Weigh 10 parts of epoxy resin, 5 parts of manganese dioxide and 1 part of diphenylguanidine successively according to parts by weight and add the...

Embodiment 2

[0038] Step 1) Modification of nano-powder: select 1-10 layers of white graphene to soak in 0.1% oleylamine aqueous solution for 24 hours, centrifuge and vacuum-dry to obtain white graphene-modified powder;

[0039] Step 2) Preparation of base rubber components: Weigh 100 parts of liquid polysulfide rubber and 5 parts of silane coupling agent sequentially according to parts by weight, add them to the mixer, mix and stir for 5 minutes, and then add 1 part in order to prepare in step 1) The modified white graphene powder and 10 parts of nano-silicon dioxide were mixed for 45 minutes at a mixing temperature of 80°C. After the components were mixed and stirred evenly, they were repeatedly ground by a three-roller mill three times to obtain the base rubber component. .

[0040] Step 3) Preparation of vulcanization components: Weigh 20 parts of epoxy resin, 15 parts of manganese dioxide and 5 parts of diphenylguanidine respectively in parts by weight and add them to the mixer at roo...

Embodiment 3

[0043] Step 1) Modification of nano-powder: select 1-10 layers of white graphene to soak in 0.1% oleylamine aqueous solution for 24 hours, centrifuge and vacuum dry to obtain white graphene-modified powder;

[0044] Step 2) Preparation of base rubber components: Weigh 100 parts of liquid polysulfide rubber and 1 part of silane coupling agent in turn according to parts by weight, add them to the mixer, mix and stir for 5 minutes, and then add 0.3 parts of step 1) preparation in sequence The modified white graphene powder and 25 parts of nano-silicon dioxide were mixed for 45 minutes at a temperature of 60°C. After the components were mixed and stirred evenly, they were repeatedly ground by a three-roller mill three times to obtain the base rubber component. .

[0045]Step 3) Preparation of the vulcanization component: Weigh 15 parts of epoxy resin, 5 parts of manganese dioxide and 1 part of diphenylguanidine successively by weight and add them to the mixer at room temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com