Application of alkaline polishing solution in inhibition of galvanic couple corrosion of copper-tantalum barrier layer

A technology of galvanic corrosion and polishing solution, applied in the application field of alkaline polishing solution and inhibiting galvanic corrosion of copper-tantalum barrier layer, can solve the problems of not achieving the ideal effect, affecting the reliability of the device, contamination by organic substances, etc. The process is convenient and reasonable, and it is beneficial to remove and reduce the effect of damage layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

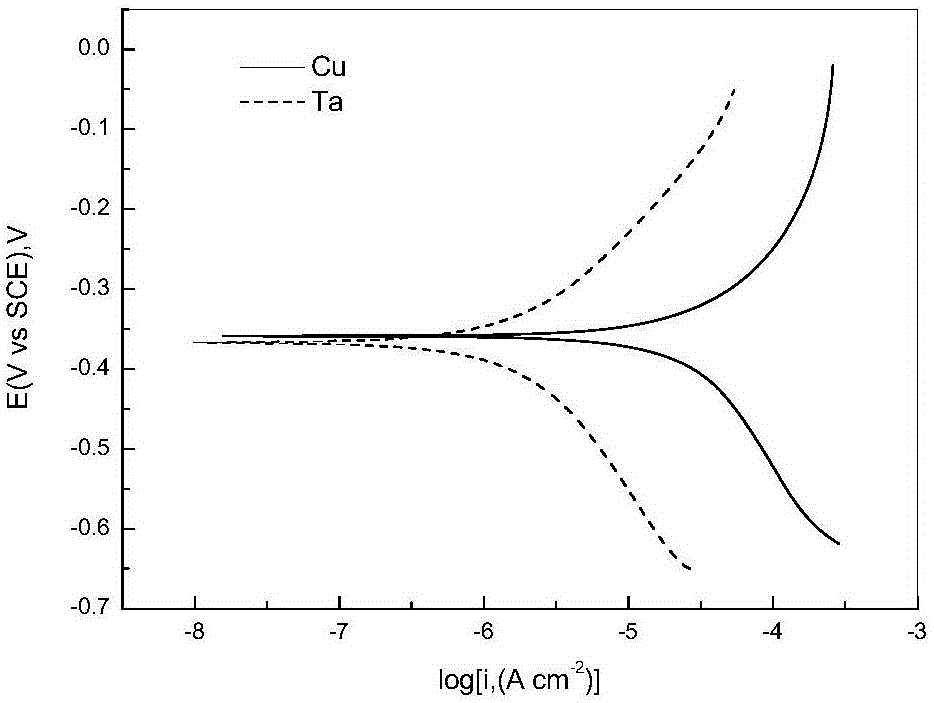

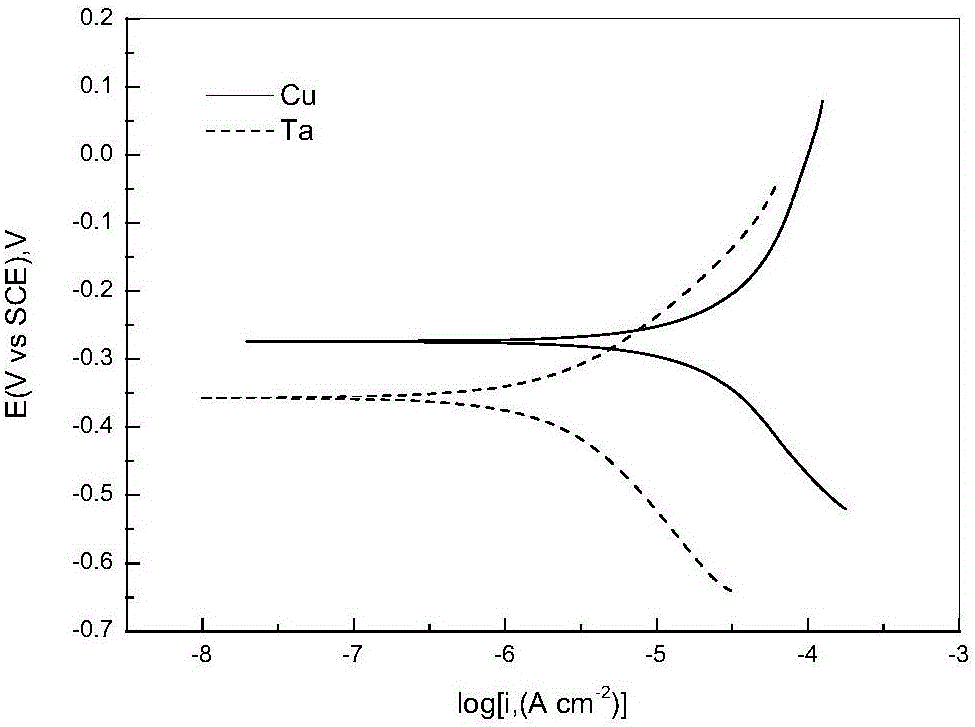

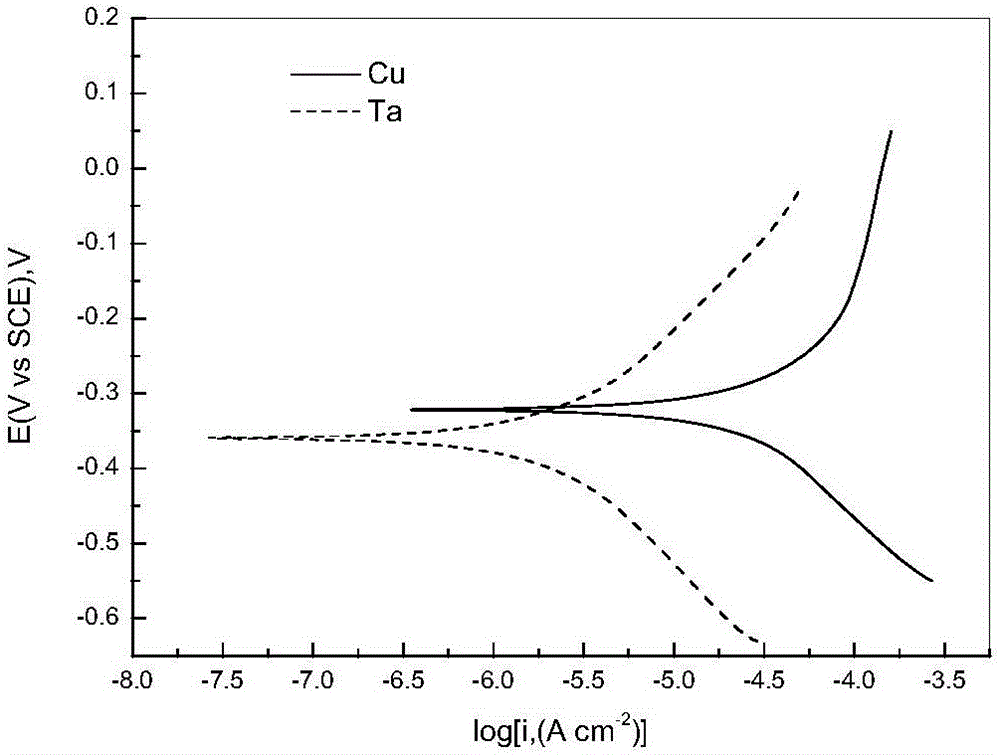

Image

Examples

Embodiment 1

[0024] Take 30gO Ⅱ -7((C 10 h 21 -C 6 h 4 -O-CH 2 CH 2 O) 7 -H) and 5g hydroxyethylethylenediamine, adding it to 200g particle diameter is 50-60nm and mass fraction is 40% SiO 2 In the hydrosol, stir at the same time, and finally make up to 1000g with deionized water to obtain a pH=9 alkaline polishing solution.

[0025] Speed test: use the prepared polishing liquid on Alpsitec-E460E polishing machine, the working pressure is 1psi, the speed of the throwing plate is 93 rpm, the speed of the throwing head is 87 rpm, and the flow rate of the polishing liquid is 300ml / min. A copper sheet (99.99% pure) with a diameter of 3 inches and a thickness of 2mm and a tantalum sheet (99.99% pure) with a diameter of 3 inches and a thickness of 2mm are polished, and the average removal rate of copper and tantalum is measured: copper is 15.3nm / min, tantalum is 22.4nm / min, the removal rate is high, and the rate selection ratio is good. Surface roughness: copper is 0.2nm, tantalum is...

Embodiment 2

[0028] Take 1g O Ⅱ -10((C 10 h 21 -C 6 h 4 -O-CH 2 CH 2 O) 10 -H) and 1g Tetrahydroxyethylethylenediamine, adding it to 300g particle diameter is 50-60nm and mass fraction is 20% SiO 2 Stir simultaneously in the hydrosol, and finally make up to 1000g with deionized water to obtain an alkaline polishing solution.

[0029] Speed test: use the prepared polishing liquid on Alpsitec-E460E polishing machine, the working pressure is 1psi, the speed of the throwing plate is 93 rpm, the speed of the throwing head is 87 rpm, and the flow rate of the polishing liquid is 300ml / min.

[0030] Polish a copper sheet with a diameter of 3 inches and a thickness of 2mm (purity is 99.99%) and a diameter of 3 inches and a thickness of tantalum sheet with a thickness of 2mm (purity is 99.99%), and the average removal rate of copper and tantalum is measured: copper is 83nm / min , Tantalum is 102nm / min, the removal rate is high, and the rate selection ratio is good. Surface roughness: coppe...

Embodiment 3

[0033] Take 10g O 20 (C12-18 h 25-37 -C 6 h 4 -O-CH 2 CH 2 O) 7 -H) and 20g triethanolamine, adding it to 500g particle diameter is 50-60nm and mass fraction is 50% SiO 2 Stir simultaneously in the hydrosol, and finally make up to 1000g with deionized water to obtain an alkaline polishing solution.

[0034] Speed test: use the prepared polishing liquid on Alpsitec-E460E polishing machine, the working pressure is 1psi, the speed of the throwing plate is 93 rpm, the speed of the throwing head is 87 rpm, and the flow rate of the polishing liquid is 300ml / min.

[0035] A copper sheet with a diameter of 3 inches and a thickness of 2mm (purity is 99.99%) and a diameter of 3 inches and a thickness of tantalum sheet with a thickness of 2mm (purity is 99.99%) are polished, and the average removal rate of copper and tantalum is measured: copper is 53nm / min , Tantalum is 62nm / min, the removal rate is high, and the rate selection ratio is good. Surface roughness: copper is 2nm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com