Waterborne polyurethane emulsion with flexural endurance and preparation method thereof

A water-based polyurethane and bending-resistant technology, which is applied in the field of water-based polyurethane emulsion and its preparation, can solve the problems of decreased adhesion of substrates, poor synthesis placement stability, and decreased flatness of composite materials, etc., and achieve good permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment polyurethane emulsion adopts the following components and the raw material of content to prepare:

[0034] a

Toluene diisocyanate

35g

b

Polyether diol (molecular weight 2000)

160g

c

Isophorone diisocyanate

290g

d

Polyester diol (molecular weight 3000)

300g

e

dimethylolbutyric acid

140g

f

110g

g

Neutralizer

70g

h

40g

i

1000g

j

Deionized water

2060g

[0035] Above-mentioned polyurethane emulsion is prepared according to the following processing steps:

[0036] Component b was stirred and dehydrated at 85° C. under vacuum, and the stirring speed was 200 rpm. After the water content in component b is less than 200ppm, stop vacuuming and return to normal pressure, lowering to 65°C. Keep stirring and add component a, keep the reaction at 65°C for 2 hours before use, the whole is c...

Embodiment 2

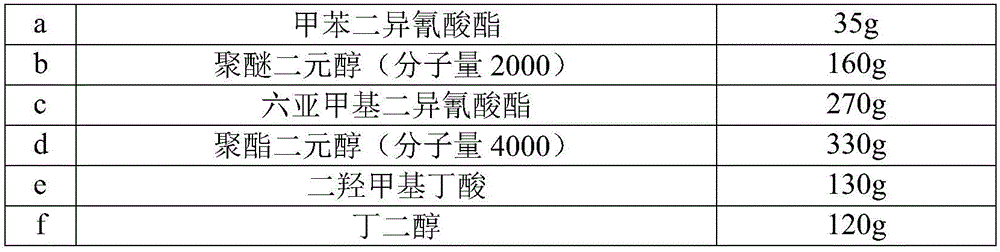

[0041] The present embodiment polyurethane emulsion adopts the following components and the raw material of content to prepare:

[0042]

[0043]

[0044] Above-mentioned polyurethane emulsion is prepared according to the following processing steps:

[0045] Component b was stirred and dehydrated at 85° C. under vacuum, and the stirring speed was 200 rpm. After the water content in component b is less than 200ppm, stop vacuuming and return to normal pressure, lowering to 65°C. Keep stirring and add component a, keep the reaction at 65°C for 2 hours before use, the whole is component A.

[0046] Component d was stirred and dehydrated at 85° C. under vacuum, and the stirring speed was 200 rpm. After the water content in component d is less than 200ppm, stop vacuuming and return to normal pressure, and keep at 85°C. Keep stirring and add component c, keep the reaction at 85°C for 2h, add component A and mix for 15min. Component e was then added, and the reaction was con...

Embodiment 3

[0050] The present embodiment polyurethane emulsion adopts the following components and the raw material of content to prepare:

[0051] a

diphenylmethane diisocyanate

60g

b

Polyether diol (molecular weight 2000)

140g

c

4,4'-Dicyclohexylmethane diisocyanate

288g

d

Polyester diol (molecular weight 3500)

350g

e

118g

f

90g

g

Neutralizer

58g

h

79g

i

1100g

j

Deionized water

2140g

[0052] Above-mentioned polyurethane emulsion is prepared according to the following processing steps:

[0053] Component b was stirred and dehydrated at 85° C. under vacuum, and the stirring speed was 200 rpm. After the water content in component b is less than 200ppm, stop vacuuming and return to normal pressure, lowering to 65°C. Keep stirring and add component a, keep the reaction at 65°C for 2 hours befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com