Low-pH ultrafine aluminophosphates cement-based grouting material

A technology of ultrafine aluminophosphate and grouting materials, which is applied in the field of cement-based grouting materials, which can solve the problems of pollution of the surrounding environment and groundwater, difficulty in injecting grout, and low strength of stone bodies, so as to increase the effective void ratio and permeability High durability, high early strength, and excellent seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

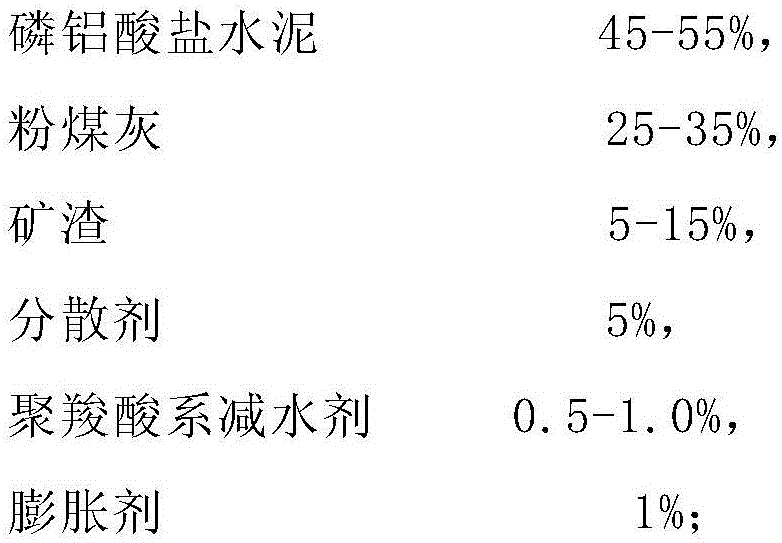

[0019] A low-pH superfine aluminophosphate cement-based grouting material, which is obtained by mixing and stirring raw materials with water at a water-to-material ratio of 1.2:1. The composition of the raw materials is as follows in terms of weight percentage: 45% aluminophosphate cement, pulverized coal Ash 35%, slag 13.5%, bentonite 5%, polycarboxylate superplasticizer (manufactured by Wuhan Huaxuan High-tech Co., Ltd.) 0.5%, magnesium oxide 1%.

[0020] The grouting material obtained in this example has a bleeding rate of 1.0% under normal pressure for 2 hours, good stability, a viscosity of 21.22mPas, good fluidity, an initial setting time of 5h35min, and a final setting time of 7h20min, indicating that it has high groutability and is free of stones. The compressive strength of body 7d is 9.8MPa, the compressive strength of 28d is 16.8MPa, the longitudinal expansion rate of 1d is 0.08%, and the pH value of 3d slurry is 10.3, which shows that the grouting material meets the...

Embodiment 2

[0022] A low-pH superfine aluminophosphate cement-based grouting material, which is obtained by mixing and stirring raw materials with water. The raw materials are composed as follows by weight percentage: 50% aluminophosphate cement, 35% fly ash, and 8.2% slag , bentonite 5%, polycarboxylate superplasticizer 0.8%, magnesium oxide 1%.

[0023] The normal pressure 2h bleeding rate of the grout obtained in this example is 1.4%, the viscosity is 26.84mPas, the initial setting time is 5h15min, the final setting time is 6h55min, the compressive strength of the stone body is 13.3MPa at 7d, and the compressive strength at 28d is 17.8MPa , 1d longitudinal expansion rate of 0.08%, 3d slurry pH value = 10.3.

Embodiment 3

[0025] A low-pH superfine aluminophosphate cement-based grouting material, which is obtained by mixing and stirring raw materials with water. The composition of the raw materials is as follows in terms of weight percentage: 55% aluminophosphate cement, 25% fly ash, and 13% slag , bentonite 5%, polycarboxylate superplasticizer 1.0%, magnesium oxide 1%.

[0026] The grouting material obtained in this example has a normal pressure 2h bleeding rate of 1.3%, a viscosity of 26.5mPas, an initial setting time of 6h50min, a final setting time of 8h35min, and a stone body with a compressive strength of 14.6MPa at 7d and a compressive strength of 16.9MPa at 28d. , 1d longitudinal expansion rate of 0.08%, 3d slurry pH value = 10.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Coagulation time | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com