Method for directly growing Prussian-blue film on FTO conductive glass

A technology of conductive glass and Prussian blue, which is applied in the field of growing Prussian blue film directly on FTO conductive glass, can solve the problems of the uniformity of the concentration film thickness, the instability of the Prussian blue film, and the low cycle stability of the film. The effect of low requirements, low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Ultrasonic dispersion of 0.66 g of potassium ferricyanide and 0.3 g of oxalic acid in 60 ml of deionized water.

[0030] 2) Add 0.5 ml of concentrated hydrochloric acid to the solution obtained in 1), then transfer it to the core of the polytetrafluoroethylene reactor, and then put a piece of FTO conductive glass with a size of 2.5 cm × 5 cm in the core of the reactor, with the conductive surface facing down , and placed in an oven at 100 °C for 24 h, then cooled to room temperature naturally.

[0031] 3) Take out the FTO conductive glass in 2) the reaction kettle, rinse it with deionized water and dry it with a hair dryer to get the Prussian blue film.

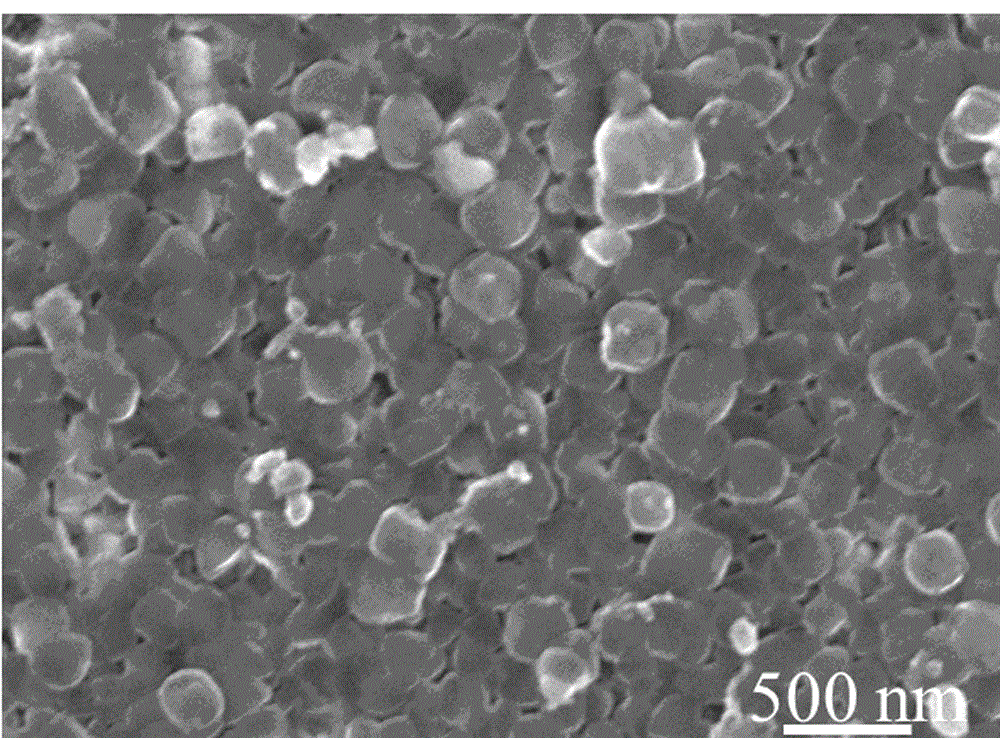

[0032] The SEM photo of the Prussian blue film prepared in the present embodiment is as follows figure 1 As shown, the particles are cubic in shape.

Embodiment 2

[0034] 1) Ultrasonic dispersion of 0.66 g of potassium ferricyanide and 0.25 g of glucose in 60 ml of deionized water.

[0035] 2) Add 1 ml of concentrated hydrochloric acid to the solution obtained in 1), then transfer it to the core of the polytetrafluoroethylene reactor, and then put a piece of FTO conductive glass with a size of 2.5 cm × 5 cm in the core of the reactor, with the conductive surface facing down , and placed in an oven at 120 °C for 3 h, then cooled to room temperature naturally.

[0036] 3) Take out the FTO conductive glass in 2) the reaction kettle, rinse it with deionized water and dry it with a hair dryer to get the Prussian blue film.

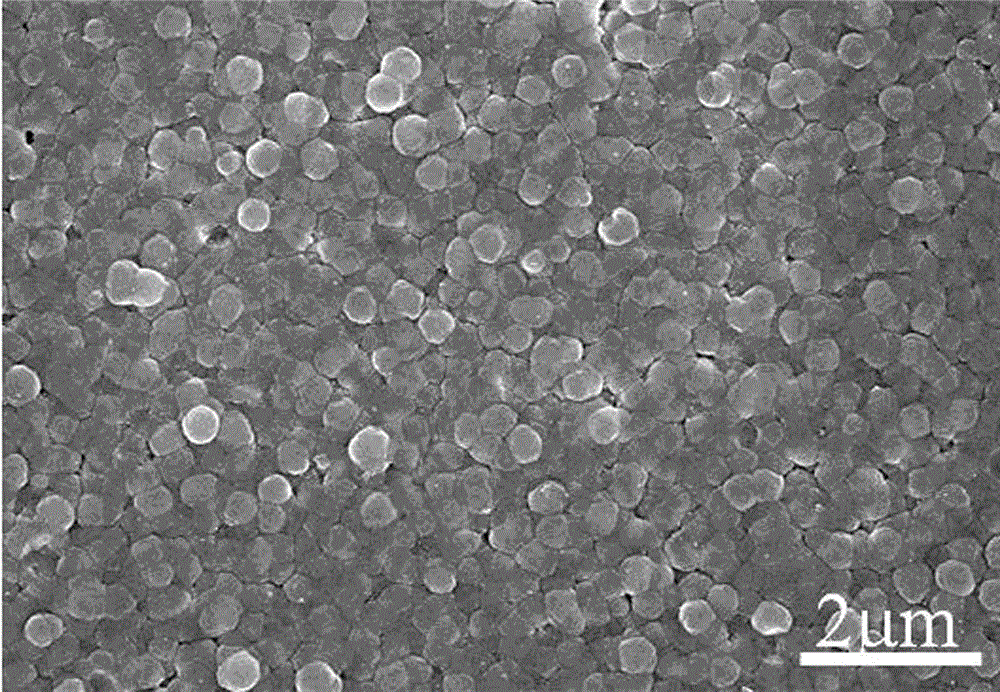

[0037] The SEM picture of the Prussian blue thin film prepared in the present embodiment is as follows figure 2 As shown, the particles are spherical; the SEM image of the cross-section is shown in the figure

[0038] 4, it is obvious that there is a layer of Prussian blue particles covering the FTO layer. Figure 5 T...

Embodiment 3

[0040] 1) 0.33 g of potassium ferricyanide and 0.5 g of polyvinylpyrrolidone were ultrasonically dispersed in 60 ml of deionized water.

[0041] 2) Add 0.5 ml of concentrated hydrochloric acid to the solution obtained in 1), then transfer it to the core of the polytetrafluoroethylene reactor, and then put a piece of FTO conductive glass with a size of 2.5 cm × 5 cm in the core of the reactor, with the conductive surface facing down , and placed in an oven at 120 °C for 12 h, then cooled to room temperature naturally.

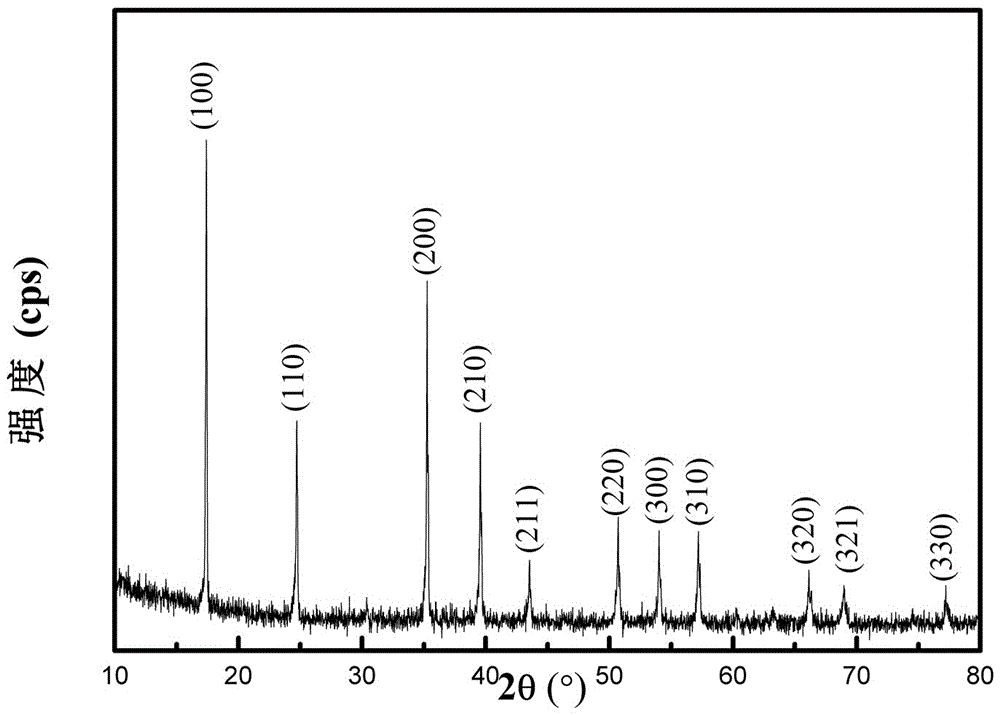

[0042] 3) Take out the FTO conductive glass in 2) the reaction kettle, rinse it with deionized water and dry it with a hair dryer to get the Prussian blue film. Its XRD spectrum is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com