Method for producing apple crisps using instantaneous pressure difference flash process

A technology for apple crisps and apple slices, which is applied in climate change adaptation, food science, etc. It can solve the problems of excessive energy intake and high oil content, and achieve the effects of less loss of nutrients, improved crispness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

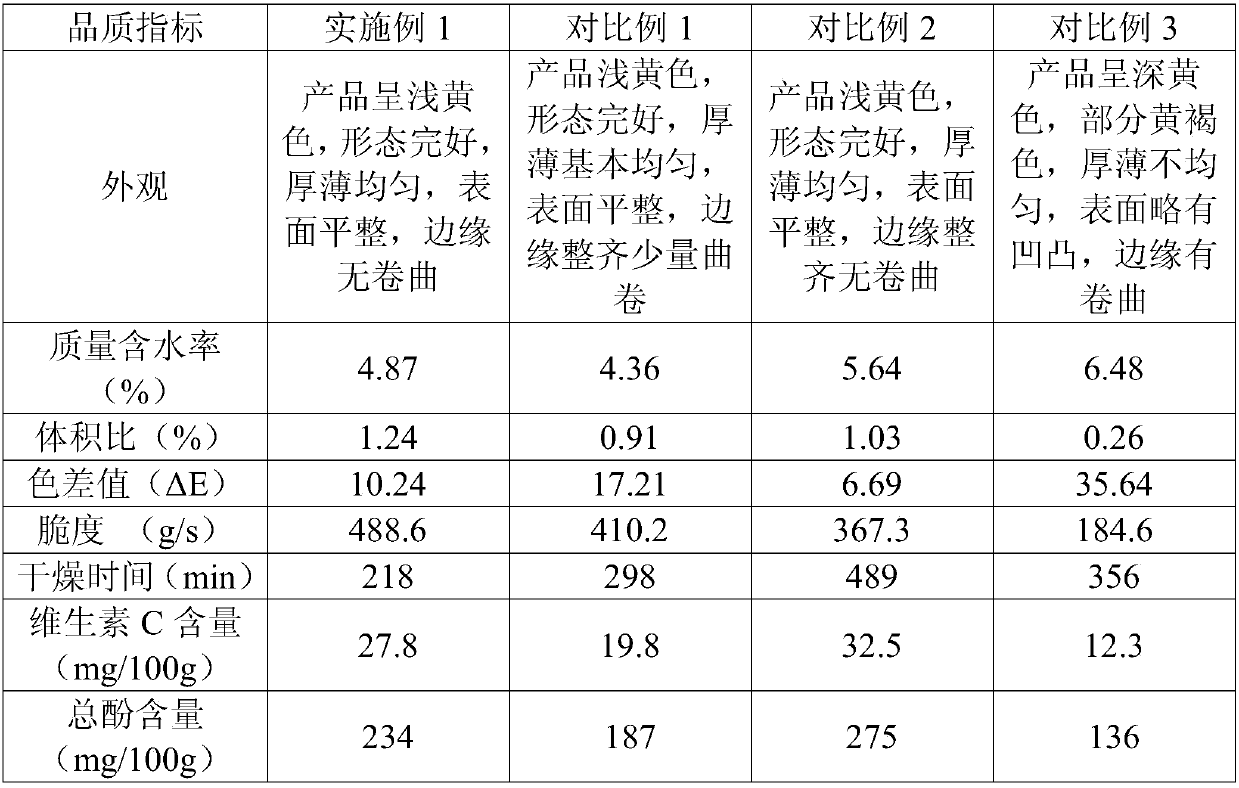

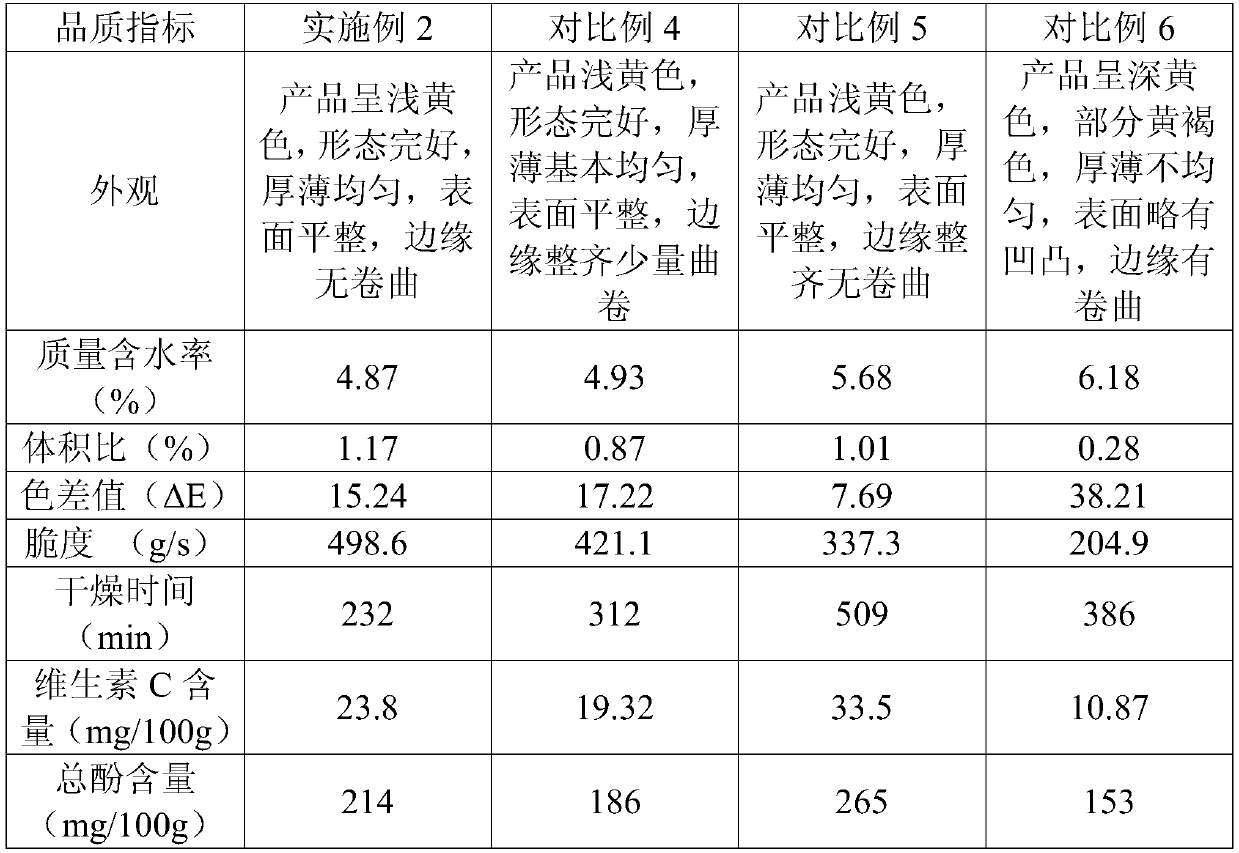

Examples

Embodiment 1

[0050] Step 1. Selection, washing, peeling, pitting and slicing:

[0051] 1a) Select eight to nine mature apples, remove corrupted, damaged, deformed and pest-infested fruits, and clean them;

[0052] 1b) Peeling and removing the core of the apple after step 1a) is cleaned manually or mechanically;

[0053] 1c) Slicing: the peeled and cored apple flesh in step 1b) is sliced by a slicer with a thickness of 8 mm.

[0054] Step 2. Instantaneous differential pressure flash pretreatment and pre-drying:

[0055] 2a) Instantaneous differential pressure flash pretreatment: put the apple slices into the pressure differential treatment chamber, and introduce hot steam to make the pressure in the pressure differential treatment chamber reach 0.3MPa, the temperature reach 133°C, and after stagnation for 40s, perform instant pressure relief treatment.

[0056] 2b) Pre-drying: use 70°C hot air to dry at a wind speed of 1.5m / s, and dry to a moisture content of about 25%.

[0057] Step 3...

Embodiment 2

[0080] Except for the following parameters, other parameters are consistent with Example 1.

[0081] Step 1, the slice thickness of the apple slices is 10mm; in step 2a) the instantaneous differential pressure flash pretreatment, the temperature is 150°C, the pressure is 0.5MPa, and the processing time is 20s; the pre-drying in step 2b) adopts vacuum drying , the drying temperature is 70°C, and the vacuum degree is 0.005MPa; in the step 3, instantaneous pressure difference flash drying, the flash temperature is 100°C, the vapor pressure in the chamber is 0.1MPa, and the pressure is released to 0.005MPa after 180s of treatment. The flash evaporation operation was repeated once; step 4, in the infrared vacuum drying, the drying temperature was 80° C., and the vacuum degree was 0.01 MPa.

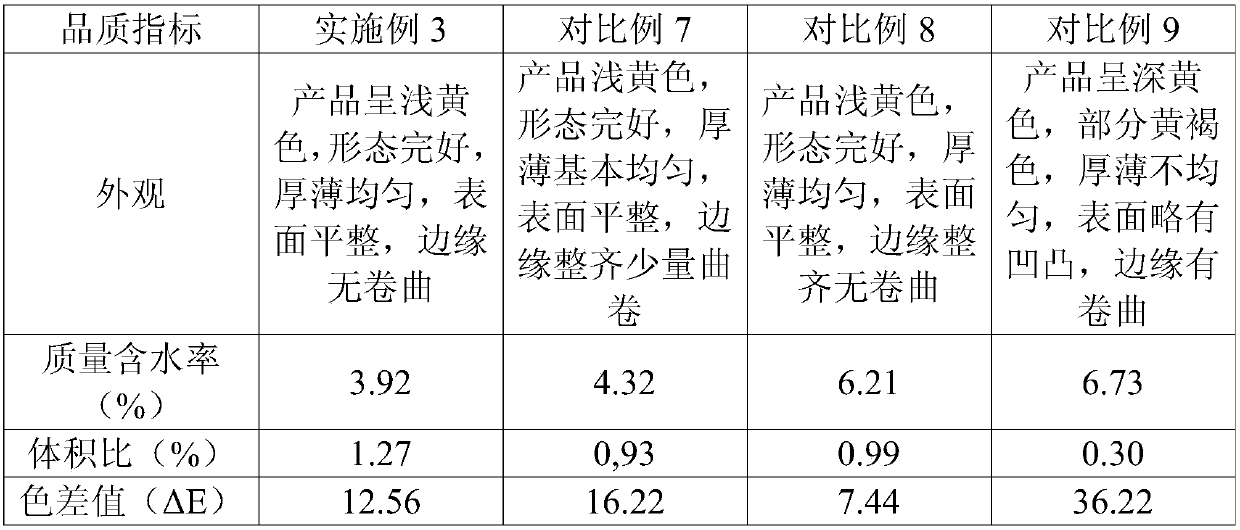

Embodiment 3

[0092] Except for the following parameters, other parameters are consistent with Example 1.

[0093] Step 1, the slice thickness of the apple slices in the middle is 6mm; the temperature of the instantaneous differential pressure flash pretreatment described in the step 2a) is 110 DEG C, the pressure is 0.15MPa, and the processing time is 40s; the predrying in the step 2b) adopts Infrared drying, the drying temperature is 75°C; in the step 3, instantaneous differential pressure flash drying, the temperature is 120°C, the pressure is 0.2MPa, the treatment is 180s, and the pressure is released to 0.01MPa. The flash evaporation operation was repeated 3 times; in step 4, infrared vacuum drying, the drying temperature was 70° C., and the vacuum degree was 0.01 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com