Assembling plate for metal guide pin connector

A technology of guide pin connector and tooling board, which is applied in the manufacture of contact boxes/bases, etc., can solve the problems of low product qualification rate, low assembly accuracy, and debris left, and achieve high product qualification rate and assembly accuracy. High, less debris leftover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

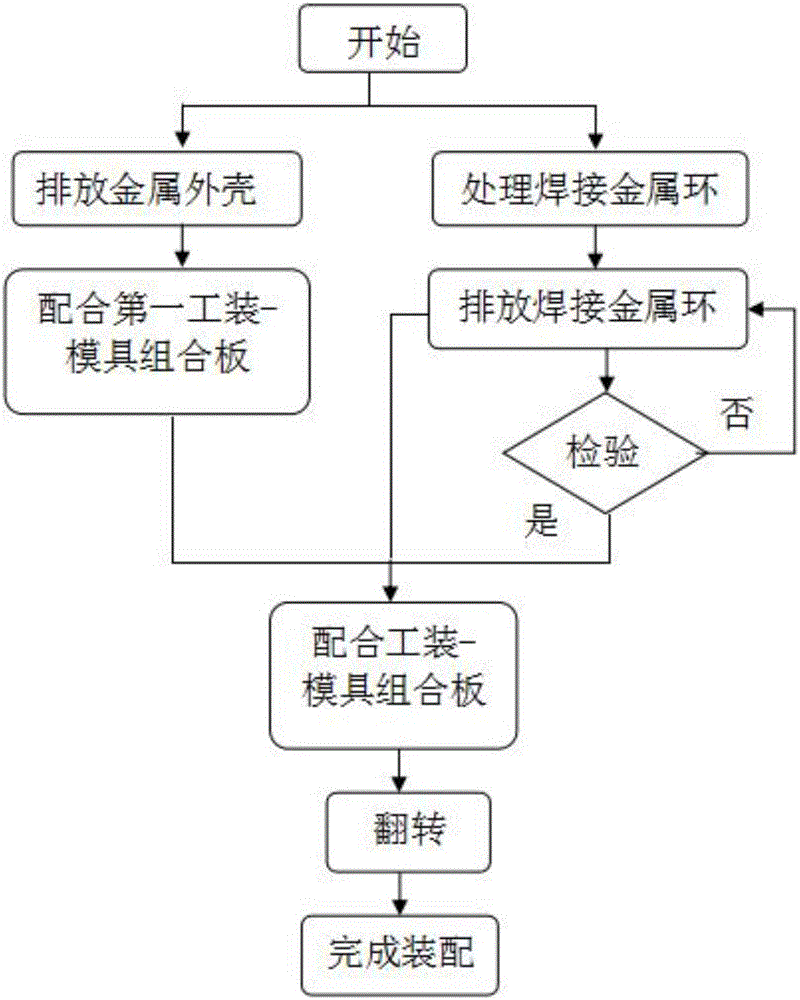

Image

Examples

Embodiment 1

[0022] The metal guide pin connector tooling plate involved in this embodiment includes a first tooling plate 5 and a second tooling plate 9; the first tooling plate 5 and the second tooling plate 9 are equal in length and width to the bottom mold 1 of the graphite mold, and the first The lower surface of the tooling plate 5 is provided with protrusions 6 arranged in an array. The height of the protrusions 6 is not lower than the difference between the depth of the sintering sinker 2 on the bottom mold 1 of the actual graphite mold and the thickness of the metal shell 4. If the height of the protrusions 6 If it is too low, the metal shell 4 is likely to shake during the flipping process of assembly, the position of the solder hole 3 is shifted, a through hole 7 is provided on each protrusion 6, and 4 cylinders are provided on the upper surface of the first tooling plate 5 Shape limit bolt 8, the limit bolt 8 and the through hole 7 are distributed in a staggered manner, and the ...

Embodiment 2

[0031] The metal guide pin connector tooling board involved in this embodiment is equipped with an automatic weighing sensor at the bottom of the cylindrical counterbore 10 on the second tooling board, and the automatic weighing sensor is connected to the central control terminal, and the central control terminal is connected to the mechanical arm and the embodiment 1. Except for the metal guide pin connector tooling board, the other structures are the same.

[0032] The assembly method of the metal guide pin connector involved in this embodiment, its specific process includes the following steps:

[0033] (1), discharge the metal shell: put the bottom mold 1 of the graphite mold into the shock sorter, and then disperse and put the metal shell 4 of the metal guide pin connector with a quantity greater than the number of the sintering sinker 2 on the bottom mold 1 of the graphite mold, The depth of the sintering sink 2 on the bottom mold 1 of the graphite mold can only discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com