Engine and braking mechanism thereof

A technology of braking mechanism and engine, applied in engine control, engine components, machine/engine, etc., can solve the problems of difficult layout and the space of the cylinder head occupied by the braking control structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

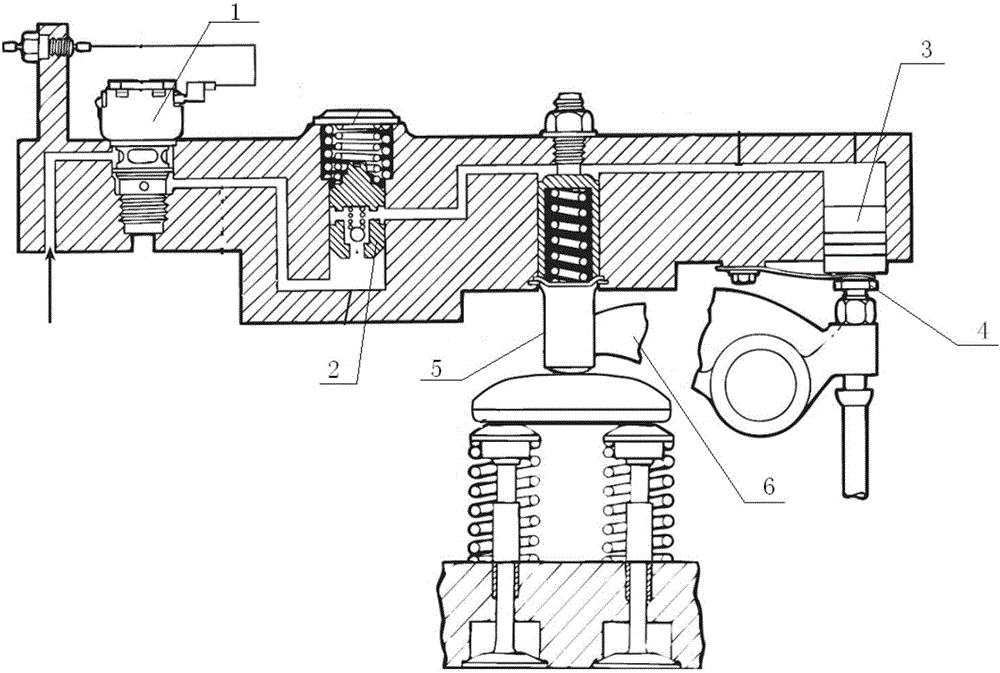

[0029] This embodiment provides a brake mechanism for an engine, which can be applied to a lower camshaft, does not occupy the space of a cylinder head, and is convenient to arrange. This specific embodiment also provides an engine including the above-mentioned braking mechanism.

[0030] Hereinafter, embodiments will be described with reference to the drawings. In addition, the embodiments shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configuration shown in the following embodiments are not limited to what is necessary as a solution to the invention described in the claims.

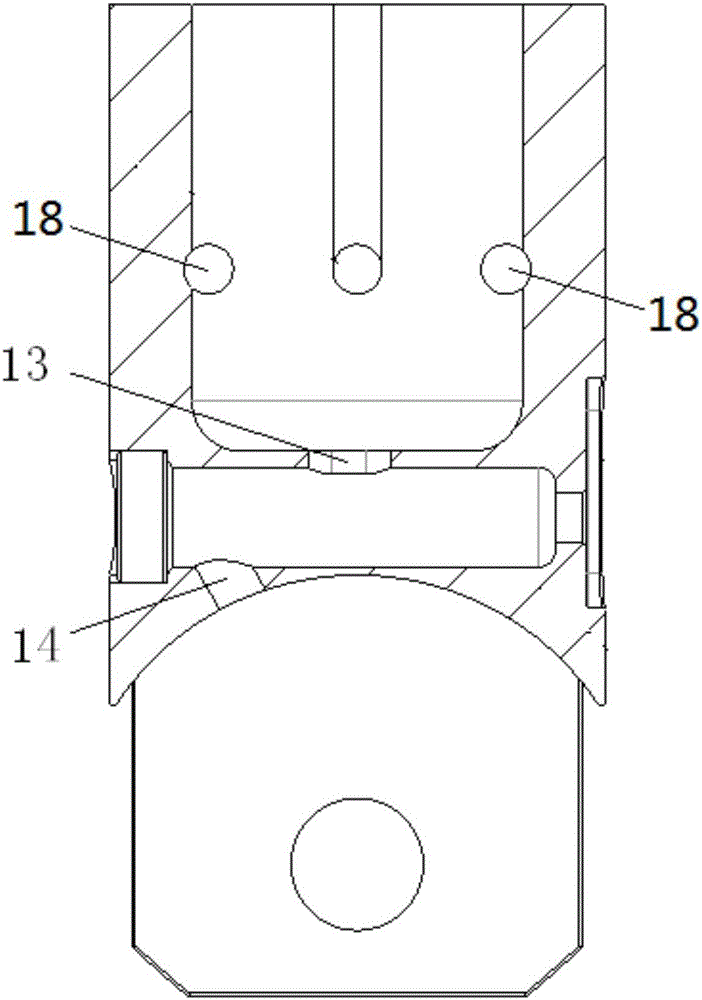

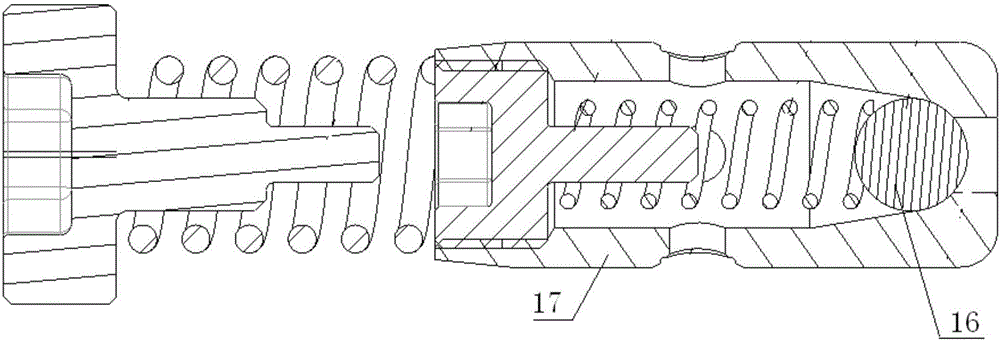

[0031] Please refer to Figure 2-Figure 6 The brake mechanism of an engine provided by this embodiment includes a camshaft, a tappet, a valve mechanism (not shown in the figure), and a first valve 16 and a second valve 17.

[0032] Among them, an exhaust cam 11 and a brake cam 12 are provided on the camshaft. When the camshaft r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com