A method for removing stickies in waste paper pulp by using high-temperature esterase

A waste paper pulp and esterase technology, applied in biochemical equipment and methods, waste paper processing, recycling technology, etc., can solve problems such as low efficiency, high energy consumption, and easy inactivation of common biological enzymes in industrial wastewater, and achieve technological Simple, low cost, and the effect of solving the problem of product quality stickies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation process of esterase EST1: the encoding gene of EST1 esterase obtained by the whole gene synthesis method is cloned into the expression vector pET23a-CBD vector to obtain the recombinant expression vector. Using CaCl 2 In the transformation method, the expression plasmid containing the EST1 esterase coding gene is transferred into the BL21 (DE3) strain to obtain the genetically engineered strain. Inoculate the strain of esterase EST1 into the LB seed medium containing Amp (100ug / ml) to expand the culture, and when the OD value reaches 0.6-0.8, inoculate the bacterial solution into the LB seed medium containing Amp (100ug / ml) at a ratio of 1:100. ml) of LB fermentation medium, shake until the OD value is 0.6-0.8, add IPTG (20mmol / L) inducer to induce expression, and harvest bacteria after 18-24h. Centrifuge the bacterial solution at 12000r / min for 10min, collect the cells on the tube wall for ultrasonic disruption, then centrifuge at 12000r / min for 10min,...

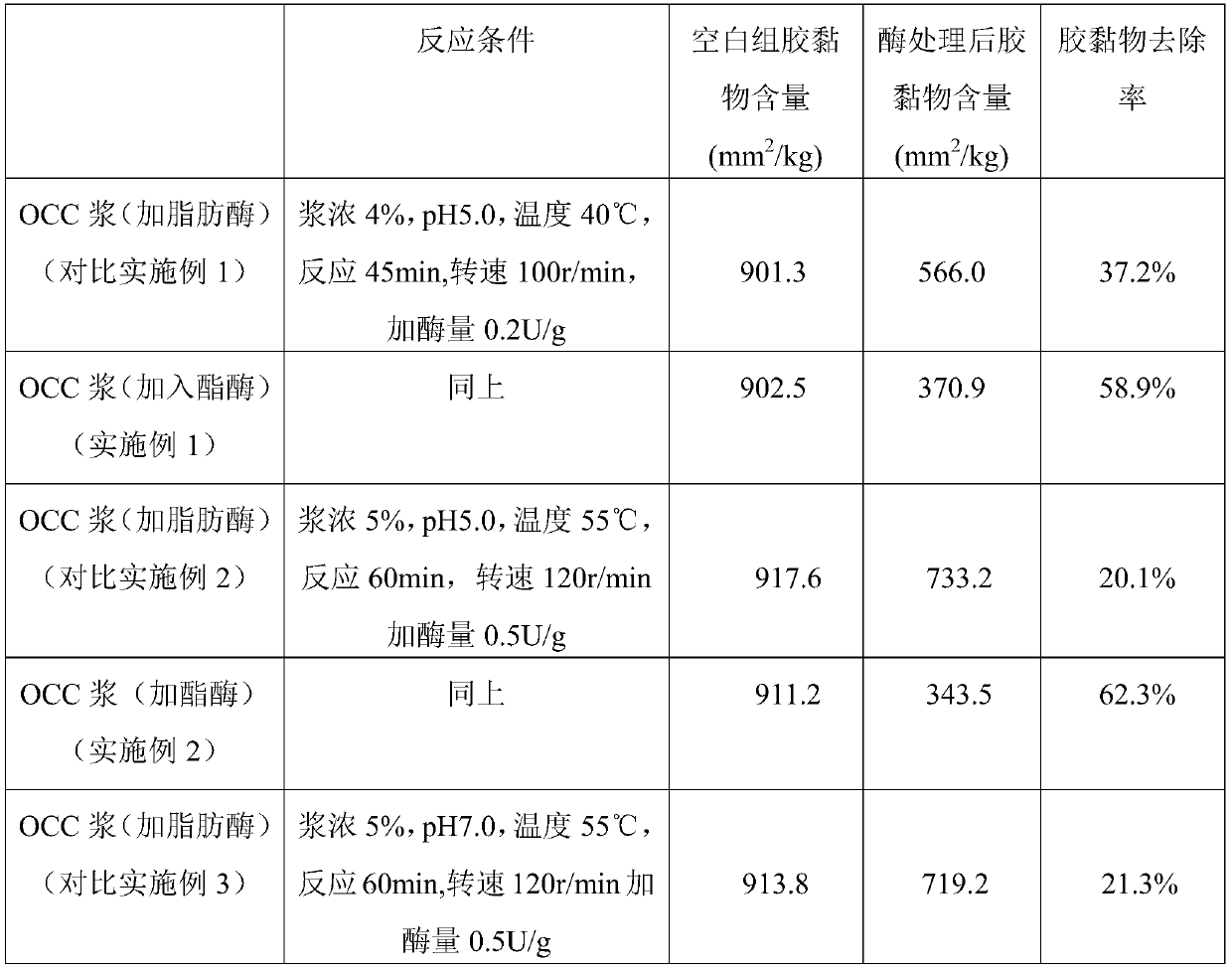

Embodiment 1

[0032] Weigh 100g OCC dry pulp, dilute the pulp to 4%, the amount of esterase EST1 added is 0.2U / g (relative to the dry pulp), the treatment temperature is 40°C, the pH is 5.0, the treatment time is 45min, and the stirring speed is 100rpm, the embodiment uses the Pulmac-MasterScreen sieving instrument to screen the slurry according to the TAPPIT-277 sticky matter assay method, then dyes and compresses the sieved sticky matter, and finally analyzes and scans it with scanning software, and then measures The content of stickies after enzyme treatment was obtained. In the case of not adding enzymes, the waste paper pulp was treated with the same conditions, and the experimental results were the stickies content of the blank group.

Embodiment 2

[0034] Weigh 100g of OCC dry pulp, dilute the pulp to 5%, the amount of esterase EST1 added is 0.5U / g (relative to the dry pulp), the treatment temperature is 55°C, the pH is 5.0, the treatment time is 60min, and the stirring speed is 120rpm, the embodiment uses the Pulmac-MasterScreen sieving instrument to screen the slurry according to the TAPPIT-277 sticky matter assay method, then dyes and compresses the sieved sticky matter, and finally analyzes and scans it with scanning software, and then measures The content of stickies after enzyme treatment was obtained. In the case of not adding enzymes, the waste paper pulp was treated with the same conditions, and the experimental results were the stickies content of the blank group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com