Antibacterial aqueous paint used for wood furniture and use method of same

A technology for wooden furniture and water-based paint, applied to biocide-containing paints, anti-fouling/underwater paints, coatings, etc., can solve problems such as lack of bactericidal effect, difficult construction, and water resistance, and achieve physical and mechanical integration Improve performance, improve physical and mechanical properties, and avoid the effect of bacteria and moths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

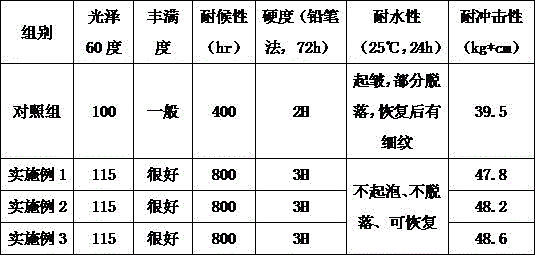

Examples

Embodiment 1

[0010] An antibacterial water-based paint for wooden furniture, prepared from the following raw materials in parts by weight: 38 parts of modified alkyd resin, 16 parts of phenylamino resin, 10 parts of 355-3 medium oil alkyd resin, superfine carbon dioxide 3 parts of zirconium, 3 parts of calcium lignosulfonate, 0.8 parts of polyvinyl alcohol, 1.2 parts of polyamide wax slurry, 3 parts of phenylmethylsulfonyl fluoride, 0.5 parts of emulsified silicone oil, 1.2 parts of heavy aromatic hydrocarbons, 0.3 parts of dipyridine latex, 23 parts of water;

[0011] Among them, the modified alkyd resin is made of the following raw materials in parts by weight: 18 parts of allyl glycidyl ether, 14 parts of titanium tetrachloride, 22 parts of mercaptosuccinic acid, 4 parts of dicumyl peroxide, Sudan red 3 parts, 8 parts of isobornyl methacrylate, 8 parts of vinyl tert-carbonate, 15 parts of phenol, 7 parts of tert-butyllithium, 1 part of tequil; the preparation method is: allyl glycidyl e...

Embodiment 2

[0014] An antibacterial water-based paint for wooden furniture, prepared from the following raw materials in parts by weight: 42 parts of modified alkyd resin, 13 parts of phenylamino resin, 8 parts of 355-3 medium oil alkyd resin, superfine carbon dioxide 3 parts of zirconium, 2 parts of calcium lignosulfonate, 0.5 parts of polyvinyl alcohol, 1.3 parts of polyamide wax slurry, 3 parts of phenylmethylsulfonyl fluoride, 0.6 parts of emulsified silicone oil, 1.4 parts of heavy aromatic hydrocarbons, 0.2 parts of dipyridine latex, 25 parts of water;

[0015] Among them, the modified alkyd resin is made of the following raw materials in parts by weight: 18 parts of allyl glycidyl ether, 14 parts of titanium tetrachloride, 20 parts of mercaptosuccinic acid, 3 parts of dicumyl peroxide, Sudan red 2 parts, 12 parts of isobornyl methacrylate, 8 parts of vinyl tert-carbonate, 15 parts of phenol, 7 parts of tert-butyllithium, 1 part of tequil; the preparation method is: allyl glycidyl e...

Embodiment 3

[0018] An antibacterial water-based paint for wooden furniture, prepared from the following raw materials in parts by weight: 35 parts of modified alkyd resin, 15 parts of phenylamino resin, 12 parts of 355-3 medium oil alkyd resin, superfine carbon dioxide 3 parts of zirconium, 2 parts of calcium lignosulfonate, 0.7 parts of polyvinyl alcohol, 1 part of polyamide wax slurry, 3 parts of phenylmethylsulfonyl fluoride, 0.6 parts of emulsified silicone oil, 1.3 parts of heavy aromatic hydrocarbons, 0.4 parts of dipyridine latex, 26 parts of water;

[0019] Among them, the modified alkyd resin is made of the following raw materials in parts by weight: 15 parts of allyl glycidyl ether, 10 parts of titanium tetrachloride, 22 parts of mercaptosuccinic acid, 3 parts of dicumyl peroxide, Sudan red 4 parts, 13 parts of isobornyl methacrylate, 10 parts of vinyl tert-carbonate, 15 parts of phenol, 6 parts of tert-butyl lithium, 2 parts of tertyl; the preparation method is: allyl glycidyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com