Graphene radiating material and preparation method thereof

A technology of heat-dissipating coatings and graphene, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as difficulty in industrialization implementation, complex heat-dissipating coating process, and poor mixing of heat-conducting materials to achieve broad application Field and scope of application, improvement of longitudinal thermal conductivity, effect of super-adhesion to substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

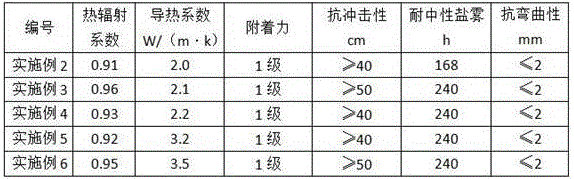

Examples

Embodiment 1

[0033] A kind of graphene heat-dissipating coating, comprises A agent and B agent, and the mass ratio of A agent and B agent is 1:1, and wherein, described A agent comprises the following components by mass percentage:

[0034] Fluorocarbon resin 40-60%, mixed solvent 30-50%, graphene 5-15%, leveling agent 0.5-1.5%, dispersant 0.5-1.5%;

[0035] The agent B includes a mixed solvent and a curing agent, and the mass ratio of the mixed solvent to the curing agent is 10:1.

[0036] Wherein, the graphene is composite graphene including ceramic filler and graphene, and the ceramic filler is such as aluminum nitride (AlN), boron nitride (BN), aluminum oxide (Al 2 o 3 ), magnesium oxide (MgO), etc., and the mass ratio of ceramic filler to graphene is 0.1-1:4. The fluorocarbon resin is one or a combination of polytetrafluoroethylene, polytrifluoroethylene, polyvinylidene fluoride, ethylene-tetrafluoroethylene copolymer, and polyvinyl fluoride. The mixed solvent is a mixture of xylen...

Embodiment 2

[0048] A kind of graphene heat-dissipating coating, comprises A agent and B agent, and the mass ratio of A agent and B agent is 1:1, and wherein, described A agent comprises the following components by mass percentage:

[0049] 40 parts of a mixture of polytetrafluoroethylene and polytrifluoroethylene resins in a mass ratio of 1:3, and a mixed solvent of xylene, n-butanol and butyl acetate in a mass ratio of 5:3:2 43 parts part, 15 parts of graphene, 0.5 part of leveling agent, and 1.5 parts of dispersant;

[0050] The agent B includes a mixed solvent and a curing agent, and the mass ratio of the mixed solvent to the curing agent is 10:1.

[0051] Present embodiment also provides a kind of preparation method of graphene heat dissipation coating, comprises the steps:

[0052] (1) Preparation of Agent A

[0053] After preparing the materials according to the above ratio, first place the fluorocarbon resin, mixed solvent, graphene, leveling agent and dispersant in the ball mill j...

Embodiment 3

[0059] A kind of graphene heat-dissipating coating, comprises A agent and B agent, and the mass ratio of A agent and B agent is 1:1, and wherein, described A agent comprises the following components by mass percentage:

[0060] 40 parts of a mixture of polytrifluoroethylene and polyvinylidene fluoride in a mass ratio of 1:3, and 50 parts of a mixed solvent of xylene, isobutanol and butyl acetate in a mass ratio of 5:3:2 part, 9 parts of graphene, 0.5 part of leveling agent, 0.5 part of dispersant;

[0061] The agent B includes a mixed solvent and a curing agent, and the mass ratio of the mixed solvent to the curing agent is 10:1.

[0062] Present embodiment also provides a kind of preparation method of graphene heat dissipation coating, comprises the steps:

[0063] (1) Preparation of Agent A

[0064] After preparing the materials according to the above ratio, put the fluorocarbon resin, mixed solvent, graphene, leveling agent and dispersant in the ball mill tank, mix the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com