Dropping pill wrapping material for improving cigarette dropping pill stability and preparation method thereof

A wrapping material and stability technology, which is applied in the field of wrapping materials and preparations of dripping pills for cigarette additives, can solve the problems that dripping pills are easily affected by the environment, difficult to find dripping pills on filter rods, and affect consumers' sensory experience, etc. , to achieve the effect of improving brittleness and environmental adaptability, improving product appearance and physical performance quality, and improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

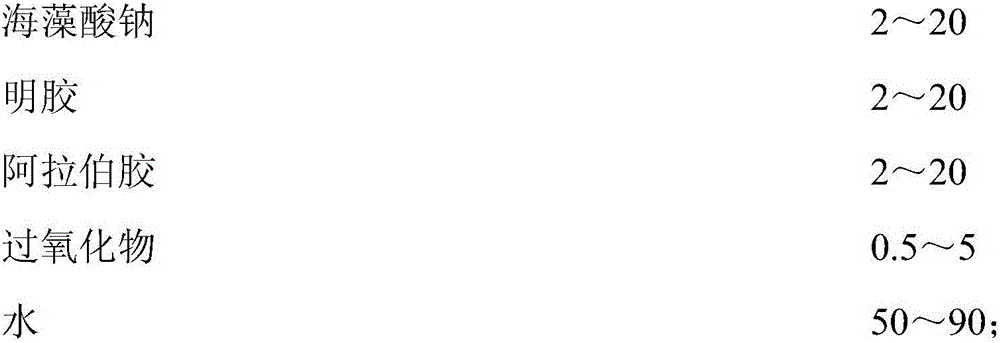

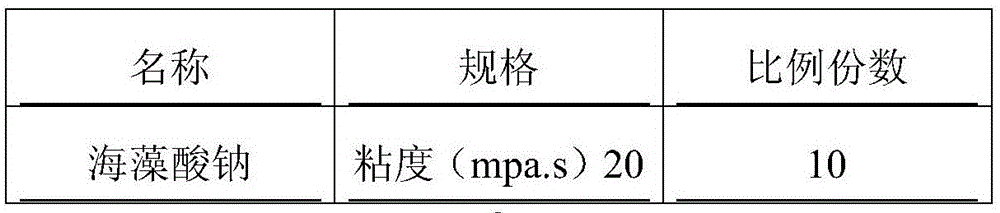

[0022] Embodiment 1: a kind of dropping pill wrapping material that improves the stability of dropping pills for cigarettes, the specific formula is as follows:

[0023]

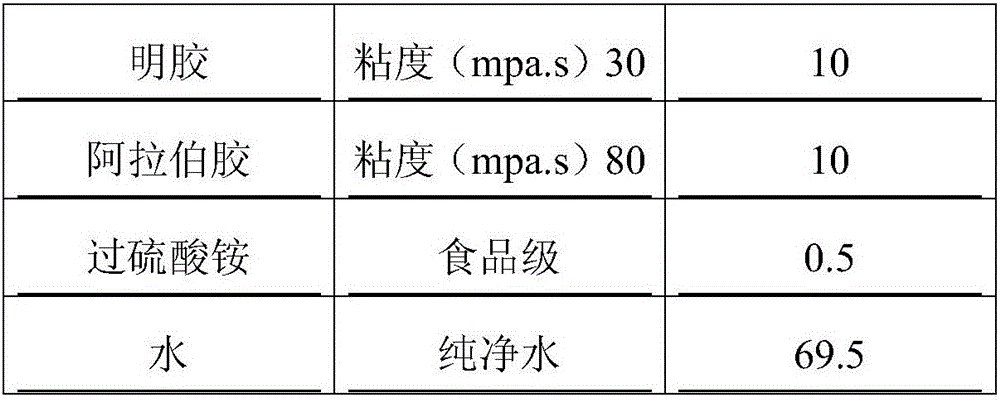

[0024]

[0025] The preparation method is as follows: first, 10 parts by weight of sodium alginate, 10 parts by weight of gelatin and 10 parts by weight of gum arabic in the above formula are dissolved with 30 parts by weight of water at 75±5°C for 0.5 hours, and then 0.5 parts by weight of Dissolve 5 parts by weight of ammonium persulfate in water at 25±5°C, stir for 0.5 hours, and finally mix all the dissolved materials with ammonium persulfate aqueous solution and add 34.5 parts by weight of water, and place in a heating interlayer Stir in the reaction tank, heat the interlayer with steam to 75±5°C, after stirring for 1 hour, the mixture is fully soluble, keep it warm for 1 hour, let it stand still, after the foam floats up, filter it at 75±5°C, and the obtained filtrate is A drop pill wrapping mate...

Embodiment 2

[0026] Embodiment 2: a kind of dripping pill wrapping material that improves the stability of cigarette dripping pills, concrete formula is as follows:

[0027] name

[0028] The preparation method is as follows: firstly, 5 parts by weight of sodium alginate, 8 parts by weight of gelatin and 9 parts by weight of gum arabic in the above formula are respectively stirred and dissolved with 10 parts by weight of water at 75±5°C for 1 hour, and then the Dissolve 1 part by weight of ammonium persulfate and 2 parts by weight of hydrogen peroxide in 10 parts by weight of water at 25±5°C, stir for 1 hour, and finally add 35 parts by weight of water to all the dissolved materials and aqueous peroxide solution Mix evenly, place in a reaction tank with a heating interlayer and stir. The interlayer is heated to 75±5°C with steam. After stirring for 1 hour, the mixture is fully soluble, and then kept for 1 hour. Filtration under the condition of ℃, the obtained filtrate is the d...

Embodiment 3

[0029] Embodiment 3: a kind of dripping pill wrapping material that improves the stability of cigarette dripping pills, concrete formula is as follows:

[0030] name

[0031] The preparation method is as follows: first, 9 parts by weight of sodium alginate, 5 parts by weight of gelatin and 9 parts by weight of gum arabic in the above formula are dissolved in 40 parts by weight of water at 75±5°C for 2 hours, and then 2 parts by weight are dissolved. Parts by weight of ammonium persulfate, 3 parts by weight of ammonium persulfate and 2 parts by weight of hydrogen peroxide are dissolved in 10 parts by weight of water at 25±5°C, stirred for 2 hours, and finally all the dissolved materials are mixed with peroxide Add 20 parts by weight of water to the aqueous solution and mix evenly, place it in a reaction tank with a heating interlayer and stir, the interlayer is heated to 75±5°C with steam, after stirring for 2 hours, the mixture is fully soluble, keep it warm for ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com