Improving the quality of non-combustible recycled tobacco leaves heated by thick slurry method and its application

A heat-not-burn and reconstituted tobacco leaf technology, which is applied in the fields of application, tobacco, and tobacco preparation, can solve the problems of reducing spicy taste and reducing irritation, and achieves the effects of difficult desorption, increased yield, and improved sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

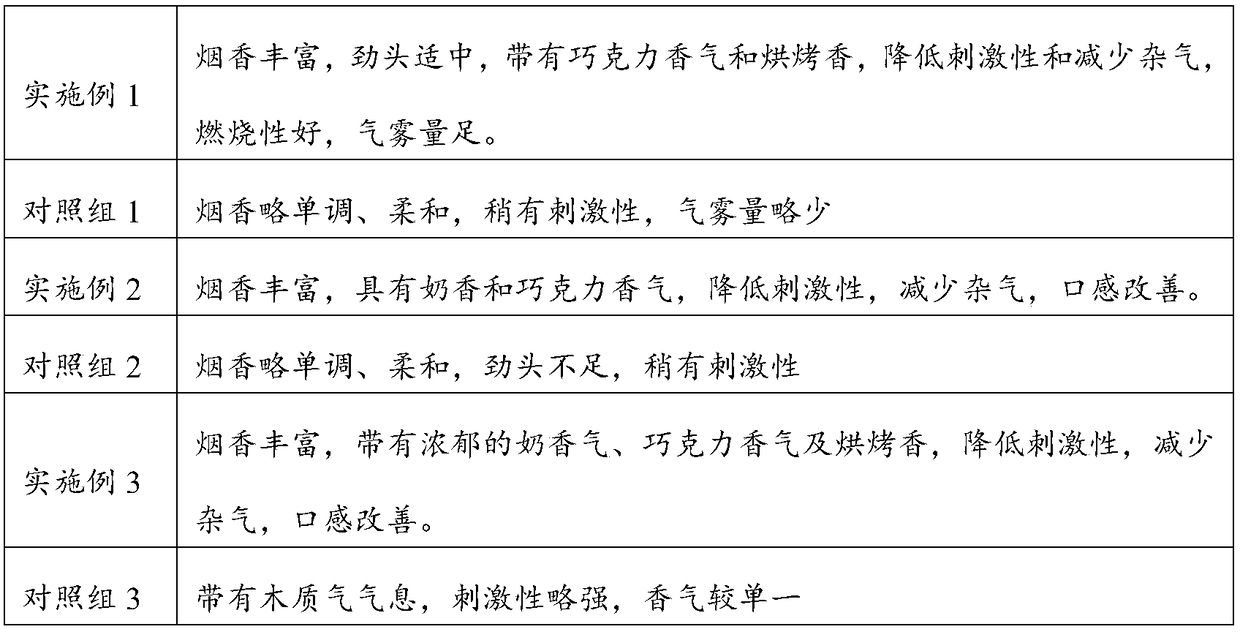

Examples

Embodiment 1

[0032] A process method for improving the quality of reconstituted tobacco leaves by heating without burning through thick slurry method includes the following steps:

[0033] (1) Crushing: crushing the tobacco raw materials to 10 mesh powder;

[0034] (2) Strain activation: Add active solid freeze-dried powder of Saccharomycopsis fibuligera and Armillariella tabescens to 5 times the mass of the sterilized corn syrup solution with a mass concentration of 5% , Placed in a 30℃ water bath to activate for 30 minutes to obtain a strain activation solution;

[0035] (3) Immobilization and adsorption of composite biological agents: the tobacco rods and shavings are washed and dried, and the tobacco rods are processed into fragments about 1 cm long, mixed with the shavings at a mass ratio of 1:0.5, and dried after autoclaving. As a strain immobilization carrier, put it into a filter bag and put it into a container, and then add the strain activation solution of step (2), and a certain amoun...

Embodiment 2

[0046] A process method for improving the quality of reconstituted tobacco leaves by heating without burning through thick slurry method includes the following steps:

[0047] (1) Crushing: crushing tobacco raw materials to 100 mesh powder;

[0048] (2) Strain activation: Add active solid freeze-dried powders of Saccharomycopsis fibuligera and Armillariella tabescens to a 13 times mass sterilized solution with a mass concentration of 16% sucrose. Place it in a 38°C water bath for activation for 45 minutes to obtain a strain activation solution;

[0049] (3) Immobilized adsorption of composite biological agents: the tobacco rods and shavings are washed and dried, and the tobacco rods are processed into fragments about 1 cm long, mixed with the shavings at a mass ratio of 1:1.1, and dried after autoclaving. As a strain immobilization carrier, put it into a filter bag and put it into a container, and then add the strain activation solution of step (2), and a certain amount of cellulase...

Embodiment 3

[0060] A process method for improving the quality of reconstituted tobacco leaves by heating without burning through thick slurry method includes the following steps:

[0061] (1) Crushing: crushing tobacco raw materials to 200 mesh powder;

[0062] (2) Strain activation: Add active solid freeze-dried powders of Saccharomycopsis fibuligera and Armillariella tabescens to a 20 times mass sterilized solution with a mass concentration of 30% glucose. Place it in a 45°C water bath to activate for 60 minutes to obtain a strain activation solution;

[0063] (3) Immobilized adsorption of composite biological agents: the tobacco rods and shavings are washed and dried, and the tobacco rods are processed into fragments about 1 cm long, mixed with the shavings at a mass ratio of 1:2, and dried after autoclaving. As a strain immobilization carrier, put it into a filter bag and put it into a container, and then add the strain activation solution of step (2), and a certain amount of cellulase and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com