Silicon carbide composite wave absorbing ceramic based on metamaterial and preparation method of silicon carbide composite wave absorbing ceramic

A composite material and composite material layer technology, applied in the field of metamaterial-based silicon carbide composite material wave absorbing ceramics and their preparation, can solve the problems of limited range of periodic structure selection, unsatisfactory high temperature wave absorption performance, and high brittleness of the dielectric base layer. , to achieve the effect of convenient engineering application, controllability and load-bearing of absorbing performance, and good absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

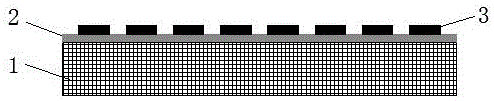

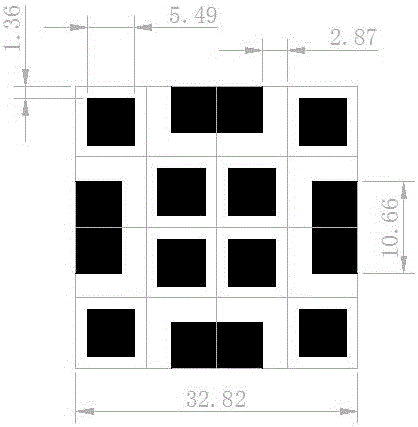

[0052] A kind of metamaterial-based silicon carbide composite wave-absorbing ceramics of the present invention, such as figure 1 As shown, it is composed of a silicon carbide composite material layer 1, an anti-oxidation adhesive layer 2 and a metamaterial layer 3 from the inside to the outside. The silicon carbide composite material layer 1 is composed of fibers with a resistivity of 10 5 ~10 6 The continuous silicon carbide fiber plain weave cloth of Ω·cm is Z-stitched into a three-dimensional braided reinforced silicon carbide composite material, the anti-oxidation adhesive layer 2 is composed of cordierite coating, and the metamaterial layer 3 is composed of capacitive periodic pattern The resistive coating is arranged periodically, and the resistive coating includes a conductive phase and an organic carrier, and the conductive phase includes glass powder and ruthenium dioxide powder. Its preparation method comprises the following steps:

[0053] (1) Select a resistivit...

Embodiment 2

[0065] A silicon carbide composite wave-absorbing ceramic based on a metamaterial of the present invention is composed of a silicon carbide composite material layer, an anti-oxidation adhesive layer and a metamaterial layer from inside to outside in sequence, and the silicon carbide composite material layer is composed of fiber resistance Rate 10 5 ~10 6 The continuous SiC fiber plain weave cloth of Ω·cm is Z-stitched into a three-dimensional braid to reinforce the SiC composite material. The coating is arranged periodically, and the resistance coating includes a conductive phase and an organic carrier, and the conductive phase includes glass powder and ruthenium dioxide powder. Its preparation method comprises the following steps:

[0066] (1) Select a resistivity of 10 5 ~10 6 The continuous silicon carbide fiber of Ω·cm is woven into a plain weave with a thickness of about 0.4 mm according to the weaving density of 5 fibers / cm in the warp and weft directions, and the pl...

Embodiment 3

[0078] A silicon carbide composite wave-absorbing ceramic based on a metamaterial of the present invention is composed of a silicon carbide composite material layer, an anti-oxidation adhesive layer and a metamaterial layer from inside to outside in sequence, and the silicon carbide composite material layer is composed of fiber resistance Rate 10 5 ~10 6 The continuous SiC fiber plain weave cloth of Ω·cm is Z-stitched into a three-dimensional braid to reinforce the SiC composite material. The coating is arranged periodically, and the resistance coating includes a conductive phase and an organic carrier, and the conductive phase includes glass powder and ruthenium dioxide powder. Its preparation method comprises the following steps:

[0079] (1) Select a resistivity of 10 5 ~10 6 The continuous silicon carbide fiber of Ω·cm is woven into a plain weave with a thickness of about 0.45mm according to the weaving density of 5 fibers / cm in the warp and weft directions, and the pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com