Two-dimensional nanometer thin film negative electrode material of lithium ion battery and preparation method of negative electrode material

A nano-film and two-dimensional nano technology, applied in the field of electrochemistry, can solve the problems of reduced capacity and stability, and achieve the effect of sufficient raw materials, good flexibility, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

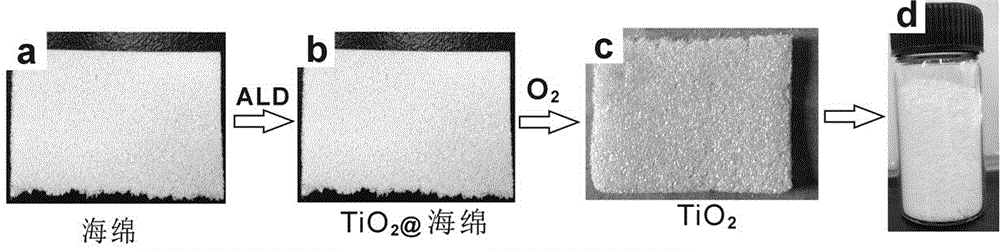

[0032] (1) Growth of TiO on the sponge by atomic layer deposition 2 nano film;

[0033] In the method of atomic layer deposition, Titanium tetrakis (dimethylamide) and deionized water are used as precursors, and the source heating temperature is controlled at 105°C and 45°C, respectively. The reaction temperature, that is, the substrate temperature is set to 150°C, and after 50 cycles of growth on a clean sponge, it is taken out to obtain a TiO-coated 2 nano film sponge;

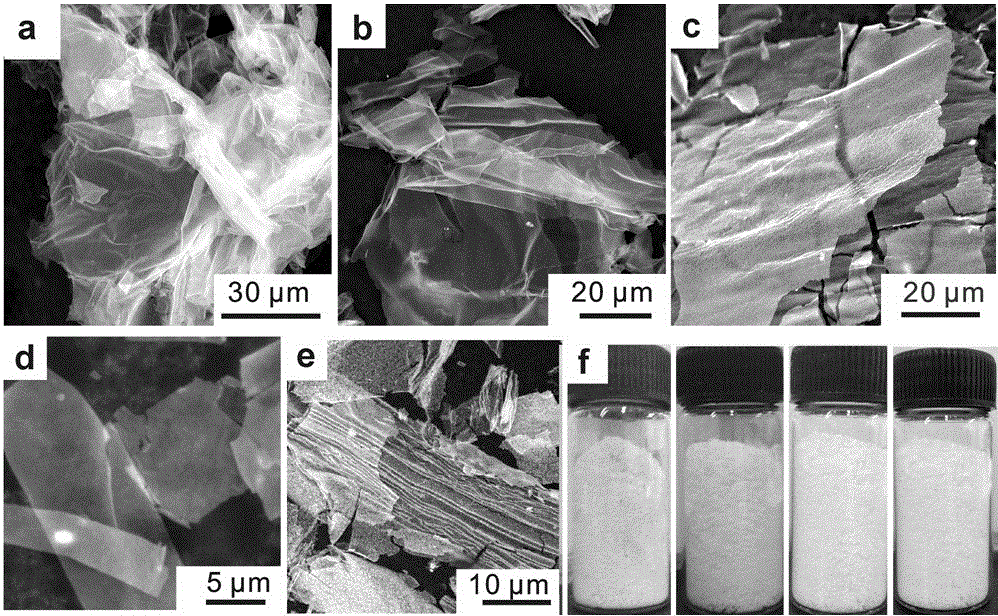

[0034] (2) will cover TiO 2 The sponge of the nanometer film is placed in an alumina crucible; the alumina crucible is placed in a tube furnace, and oxygen is introduced for heat treatment. Raise the temperature at a heating rate of 10 °C / min, the burning temperature is 500 °C, the holding time is 3 hours, and the flow rate of oxygen is 0.6 liters / min; after the sample is naturally cooled, take it out, and place the sample in acetone, alcohol and After ultrasonic cleaning in deionized water, a large numb...

Embodiment 2

[0037] (1) Growth of TiO on a clean sponge by atomic layer deposition 2 nano film;

[0038] In the atomic layer deposition method, Titanium tetrakis (dimethylamide) and deionized water are used as precursors, and the temperatures are controlled at 105°C and 45°C, respectively. The reaction temperature, that is, the substrate temperature is set to 150 °C, and after 200 cycles of growth on a clean sponge, it is taken out to obtain the coated TiO 2 nano film sponge;

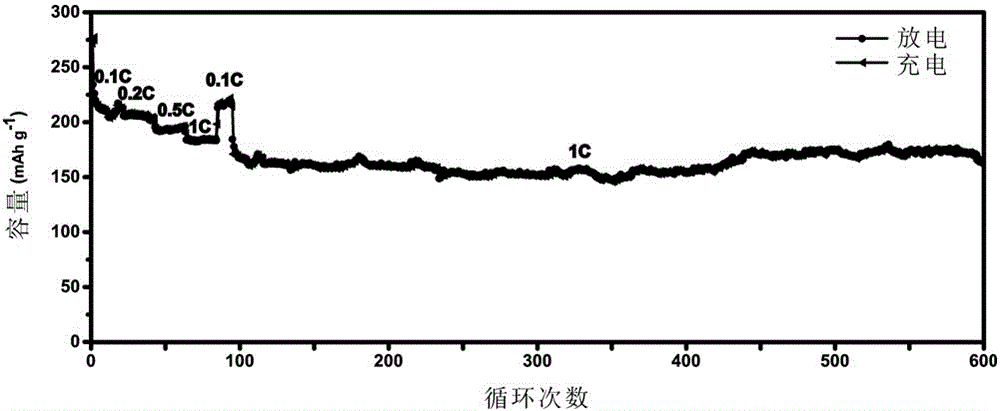

[0039] (2) will cover TiO 2 The sponge of the nanometer film is placed in an alumina crucible; the alumina crucible is placed in a tube furnace, and oxygen is introduced for heat treatment. Raise the temperature at a heating rate of 10°C / min, the burning temperature is 500°C, the holding time is 3 hours, and the oxygen flow rate is 0.6 liters / min; after the sample is naturally cooled, take it out, and place the sample in acetone, alcohol and Ultrasonic cleaning in deionized water can obtain a large number of two...

Embodiment 3

[0044] (1) Growth of TiO on a clean sponge by atomic layer deposition 2 nano film;

[0045] In the atomic layer deposition method, Titanium tetrakis (dimethylamide) and water are used as precursors, and the temperatures are controlled at 105°C and 45°C, respectively. The reaction temperature, that is, the substrate temperature is set to 150 °C, and after 400 cycles of growth on a clean sponge, it is taken out to obtain the coated TiO 2 nano film sponge;

[0046] (2) will cover TiO 2 The sponge of the nanometer film is placed in an alumina crucible; the alumina crucible is placed in a tube furnace, and oxygen is introduced for heat treatment. Raise the temperature at a heating rate of 10°C / min, the burning temperature is 500°C, the holding time is 3 hours, and the oxygen flow rate is 0.4 liters / min; after the sample is naturally cooled, take it out, and place the sample in acetone, alcohol and After ultrasonic cleaning in deionized water, a large number of two-dimensional n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com