Method for reducing injection damage to realize enhanced hemt device and enhanced hemt device

An injection damage and enhancement technology, applied in the field of microelectronics, can solve the problems of etching, small saturation current, affecting the mobility of two-dimensional electron gas, etc., and achieve the effect of simple manufacturing process, large leakage current output, and mature process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

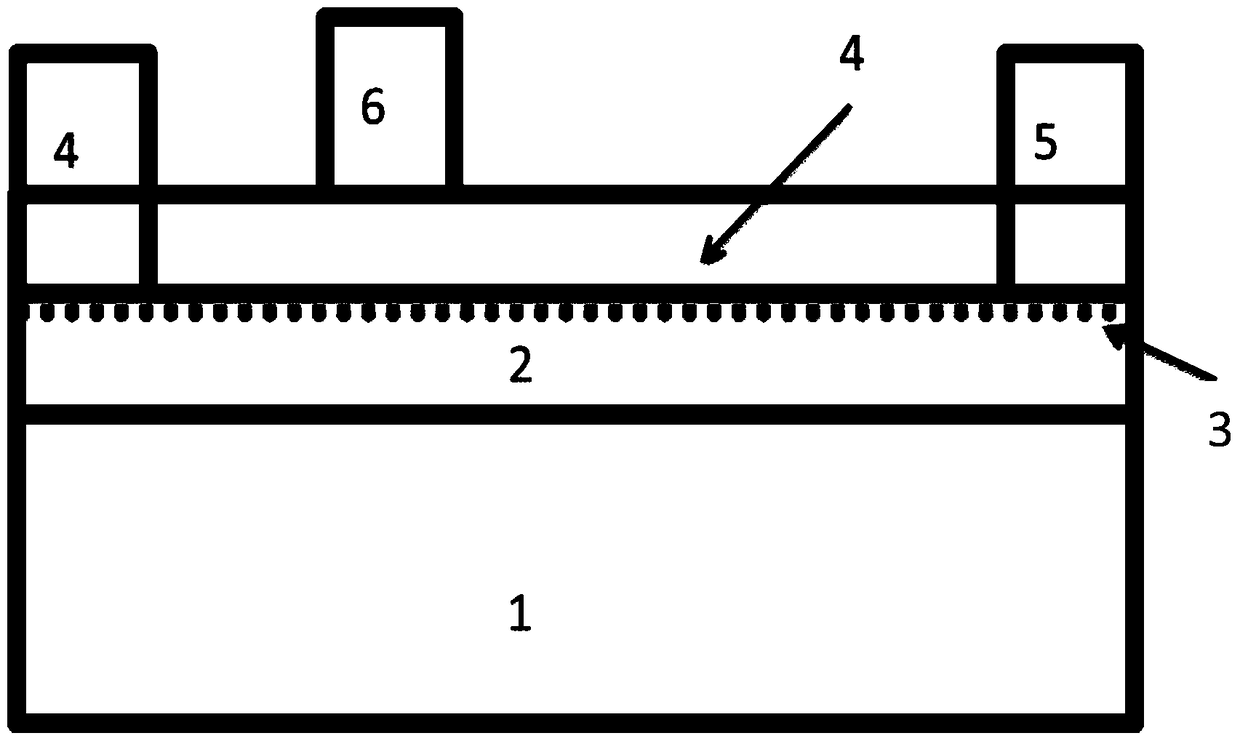

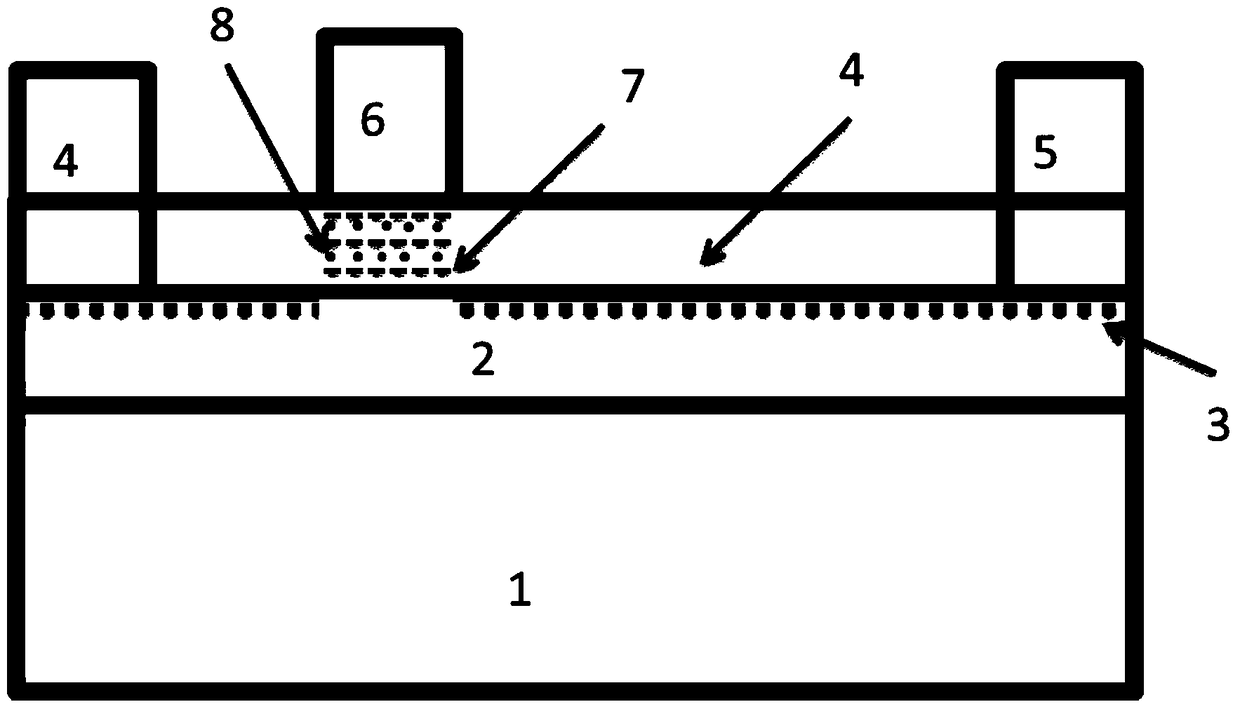

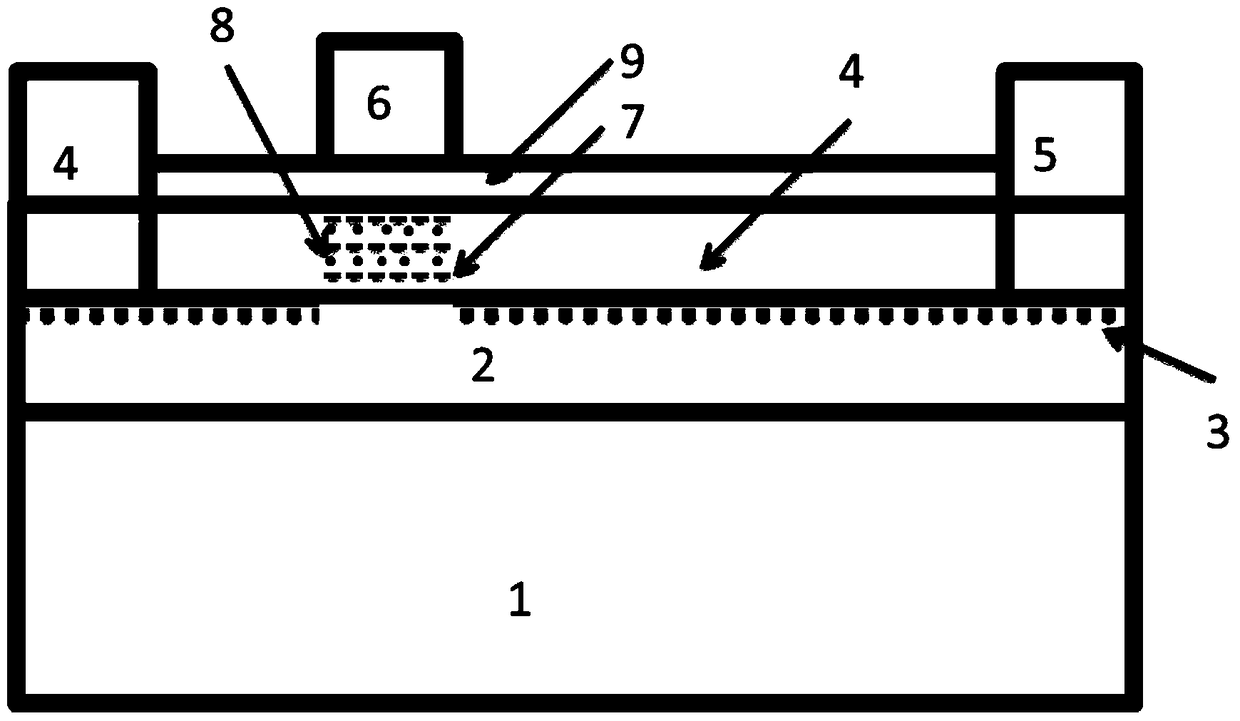

[0067] Embodiment 1 please refer again figure 2 and image 3 , the HEMT has: a first semiconductor 2 (GaN), and a second semiconductor 4 (AlGaN) formed on the first semiconductor 2 . The first semiconductor 2 is not intentionally doped. The second semiconductor 4 may be doped with n-type impurities, or may not be doped. The band gap of the second semiconductor 4 is wider than that of the first semiconductor 2 . The thickness of the second semiconductor 4 is about 15 to 30 nm. The first semiconductor 2 and the second semiconductor 4 form a heterostructure, forming a two-dimensional electron gas (2DEG) at the interface.

[0068] This HEMT has a drain electrode 6 and a source electrode 5 arranged at a distance from each other. The drain electrode 6 and the source electrode 5 extend through the second semiconductor 4 to the first semiconductor 2 and are connected to the two-dimensional electron gas in the channel. The drain electrode 6 and the source electrode 5 are ohmic c...

Embodiment 2

[0071] Embodiment 2 This MIS-HEMT has a first semiconductor 2 (GaN), and a second semiconductor 4 (AlGaN) formed on the first semiconductor 2 . The first semiconductor 2 is not intentionally doped. The second semiconductor 4 may be doped with n-type impurities, or may not be doped. The band gap of the second semiconductor 4 is wider than that of the first semiconductor 2 . The thickness of the second semiconductor 4 is about 15 to 30 nm. The first semiconductor 2 and the second semiconductor 4 form a heterostructure, forming a two-dimensional electron gas (2DEG) at the interface.

[0072]This MIS-HEMT has a drain electrode 6 and a source electrode 5 arranged at predetermined intervals. The drain electrode 6 and the source electrode 5 extend through the second semiconductor 4 to the first semiconductor 2 and are connected to the two-dimensional electron gas in the channel. The drain electrode 6 and the source electrode 5 are made of multi-layer metals (eg Ti / Al / Ti / Au or Ti / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com