Positive photosensitive resin composition, pattern forming method and application thereof

A photosensitive resin and composition technology, applied in optics, optomechanical equipment, nonlinear optics, etc., can solve the problem that the pattern contrast and peelability of positive photosensitive resin compositions cannot meet the requirements of the industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

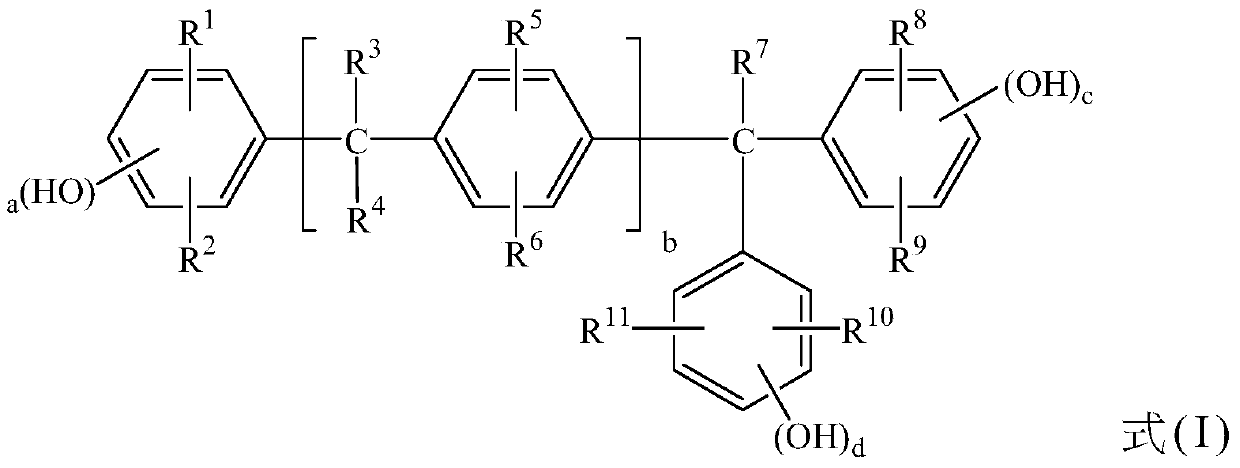

Method used

Image

Examples

Synthetic example A-1-1

[0111] A nitrogen inlet, a stirrer, a heater, a condenser tube and a thermometer are arranged on a four-necked conical flask with a volume of 1000 milliliters, and after introducing nitrogen, add 0.4 mole of m-cresol, 0.5 mole of p-cresol, 0.1 mole of 3 , 4-xylenol, 0.65 moles of formaldehyde and 0.2 moles of oxalic acid. Stir slowly to raise the temperature of the reaction solution to 100°C, and polycondense at this temperature for 6 hours. Then, the temperature of the reaction solution was raised to 180° C., and dried under reduced pressure at a pressure of 10 mmHg to obtain the xylenol-type novolac resin (A-1-1) after the solvent was devolatilized.

[0112] Synthesis Examples A-1-2 to A-1-6

[0113] Synthesis Examples A-1-2 to A-1-6 use the same preparation method as that of the xylenol-type novolak resin of Synthesis Example A-1-1, except that Synthesis Example A-1-2 To A-1-6 is to change the type and usage amount of raw materials in the novolac resin, and its formula is...

Synthetic example A-2-1

[0115] Set nitrogen inlet, stirrer, heater, condenser and thermometer on a four-necked conical flask with a volume of 1000 ml, add 0.7 mole m-cresol, 0.3 mole p-cresol, 0.7 mole formaldehyde after introducing nitrogen and 0.015 moles of oxalic acid. Stir slowly to raise the temperature of the reaction solution to 100°C, and polycondense at this temperature for 6 hours. Then, the reaction solution was heated up to 180° C., and dried under reduced pressure at a pressure of 10 mmHg, and the solvent was evaporated to obtain a hydroxyl-type novolac resin (A-2-1).

Synthetic example A-2-2

[0116] Synthesis Example A-2-2 and A-2-3

[0117] Synthesis Example A-2-2 and A-2-3 use the same preparation method as the synthetic method of the hydroxyl type novolak resin of Synthesis Example A-2-1, the difference is that Synthesis Example A-2-2 and A -2-3 is to change the type, usage amount and reaction temperature of the raw materials in the novolac resin. The formula and preparation conditions are shown in Table 1 respectively, and will not be repeated here.

[0118] Synthesis Comparative Example A-3-1

[0119] In a three-necked flask with a capacity of 500 ml, add 0.30 mole of methyltrimethoxysilane, 0.65 mole of phenyltrimethoxysilane, 0.05 mole of 3-(triethoxysilyl) propyl succinic anhydride and 200 grams of propylene glycol monoethyl ether, and added an aqueous oxalic acid solution (0.40 grams of oxalic acid / 75 grams of water) within 30 minutes while stirring at room temperature. Next, immerse the flask in an oil bath at 30°C and stir for 30 minutes, then raise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com