Field runoff and sediment automatic monitoring equipment and monitoring method

An automatic monitoring and runoff technology, applied in the direction of measuring devices, material weighing, instruments, etc., can solve the problems of large measurement errors, difficult power supply, uneven distribution, etc., achieve low production and maintenance costs, simple and reliable design structure, and calculation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

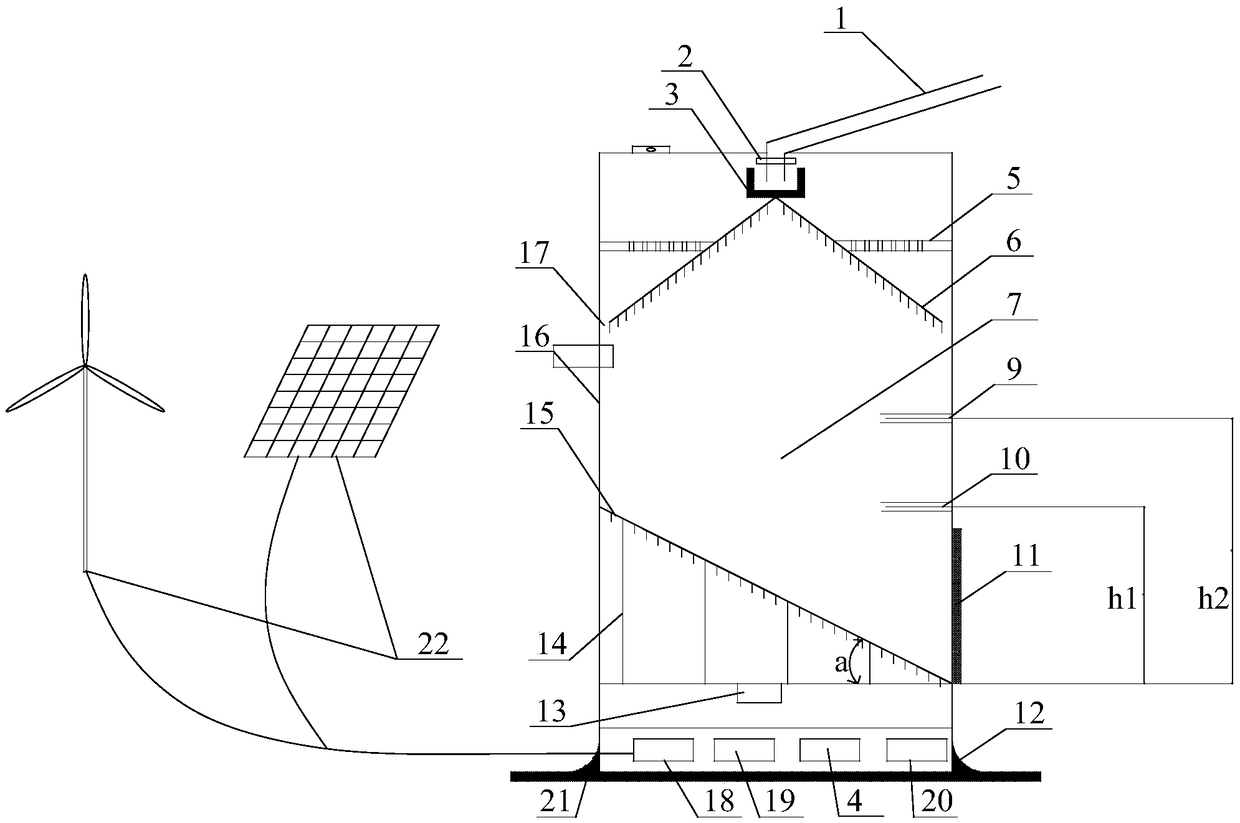

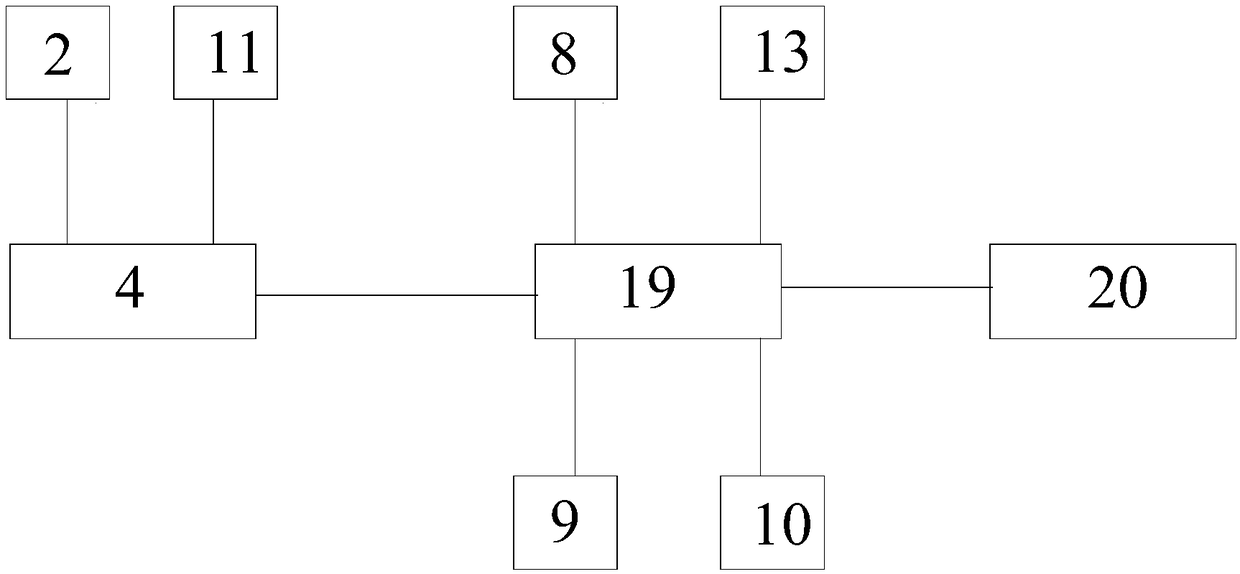

[0040] 1) When it rains, the single-chip microcomputer 19 controls the water inlet electromagnetic valve 2 to open through the electromagnetic valve controller 4, and the water outlet electromagnetic valve 11 closes, and the runoff flows into the concave overflow tank 3 through the runoff inlet pipe 1, and the concave overflow tank 3 can weaken the direct impact force of the runoff , and can disperse the sediment in the runoff. The runoff overflows with the concave overflow tank 3 and then is filtered by the support filter 5 and then flows to the upper surface of the conical water guide plate 6. After the runoff is evenly distributed by the conical water guide plate 6, it passes through the gap 17 flows into the storage chamber 7 along the side wall of the cylinder 16, so that the incoming water avoids directly impacting the liquid surface, and the elapsed time t 1 When the water level reaches the lower water level probe 10, the water level probe 10 sends a signal to the single...

Embodiment 2

[0045] Step (1) is the same as the monitoring process embodiment 1, the difference is that when the water level reaches the lower water level probe 10, the water will continue to flow in until the water level passes the time t 2 When reaching the upper water level probe 9, the load cell 13 records and sends the information into the single-chip microcomputer 19 to store it as the weight M 2 , timer 8 records time t 2 And the information is transferred to the single-chip microcomputer 19 and stored as t 2 , the single-chip microcomputer 19 and the electromagnetic valve control unit 4 control the water inlet electromagnetic valve 2 to close, and the water outlet electromagnetic valve 11 to open, so that the liquid in the flow storage chamber 7 can be quickly discharged;

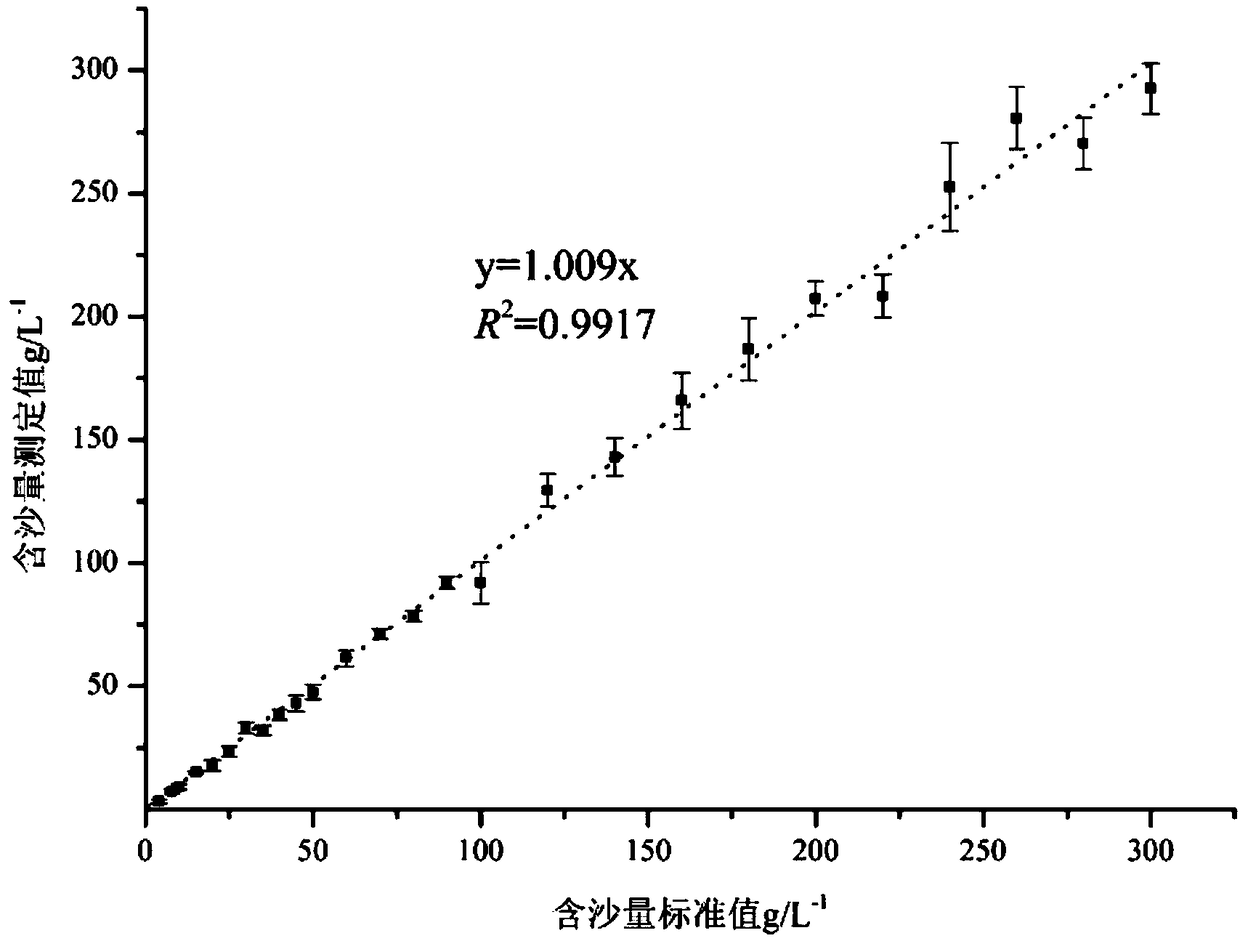

[0046] In step (2), carry out following data processing in single-chip microcomputer 19: combine the height of known lower water level probe 10 i.e. low water level h 1 , The height of the upper water level pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com