Automatic flowing pipe ore pulp switch valve

A valve and pulp technology, applied in the field of artesian tube pulp switching valve, can solve the problems of sludge accumulation, low pressure, blockage of pipelines, etc., and achieve the effects of convenient pulp switching, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

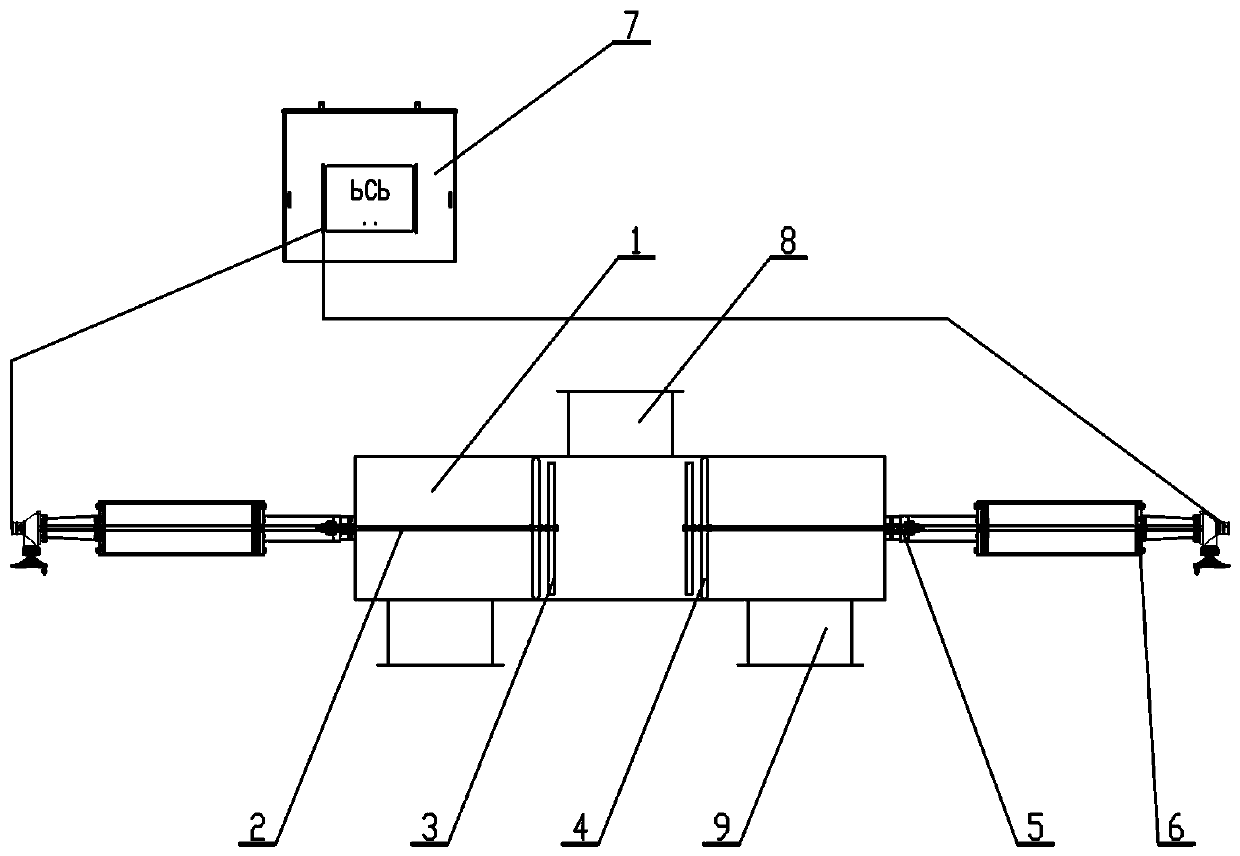

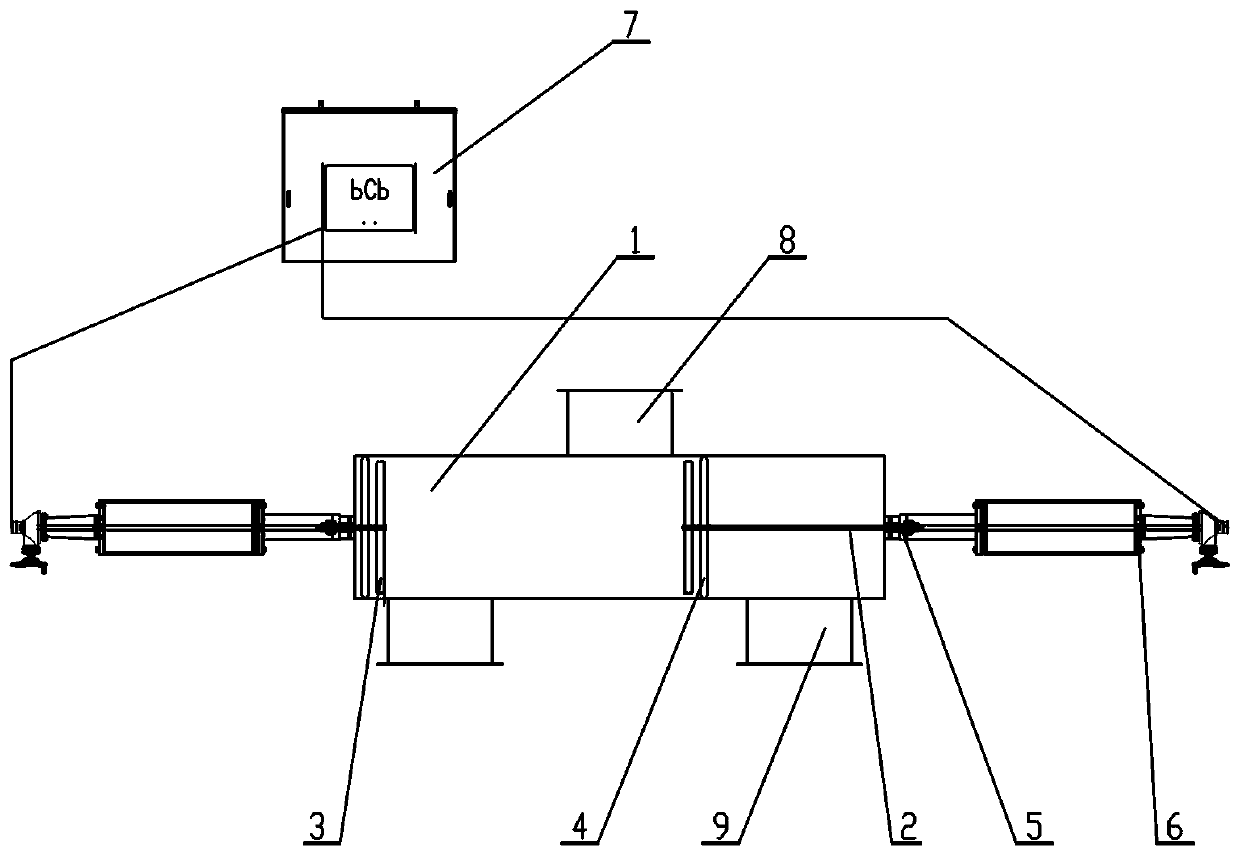

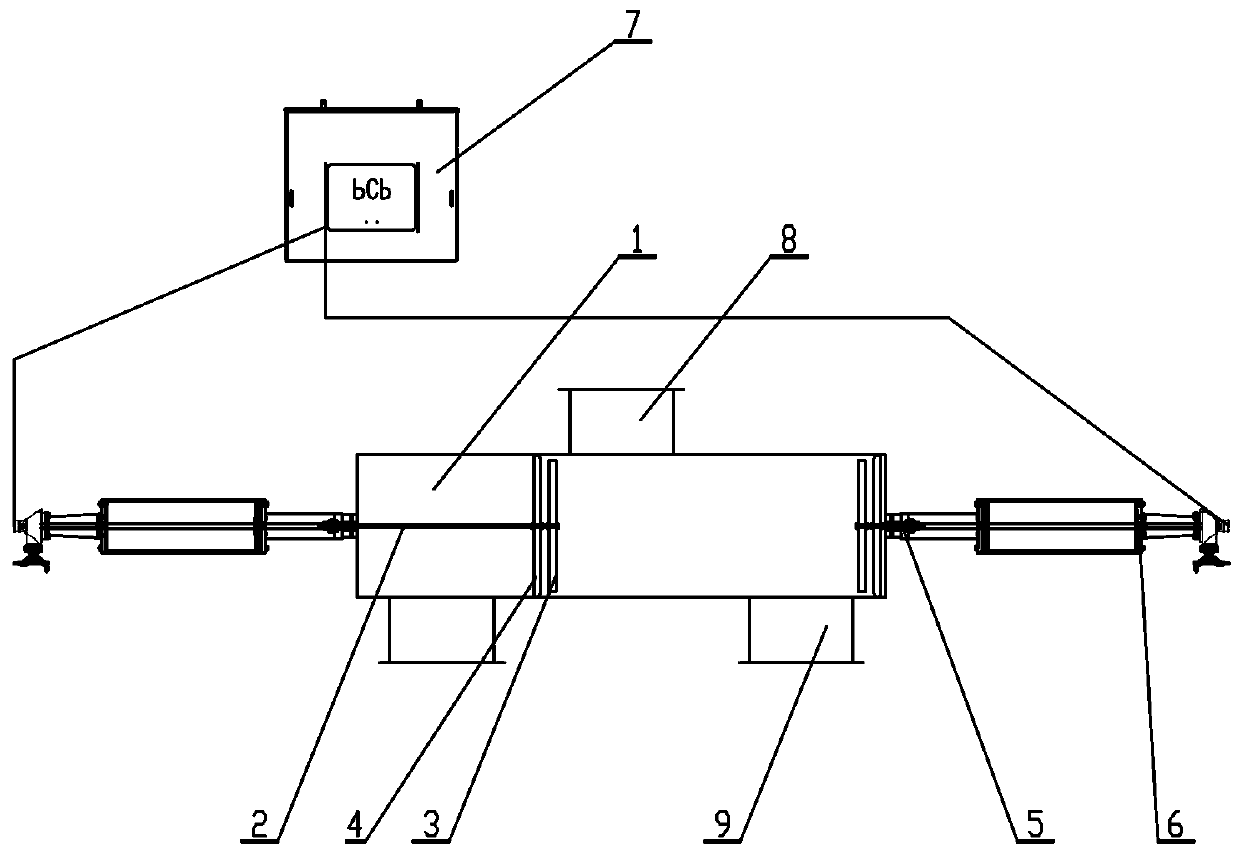

[0017] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 , 2 As shown in and 3, the gravity pipe slurry switching valve of the present invention is characterized in that it includes a valve body arranged between the inlet flange pipe 8 and the two outlet flange pipes 9, and two valve bodies connected to the two ends of the valve body An actuator 6, a control mechanism 7 connected to the two actuators 6 respectively, the inlet flange pipe 8 is located at the center of the valve body, and the valve body includes a cylindrical shell 1, which is arranged here Two circular rams 3 and two circular sealing plugs 4 arranged symmetrically with the center line of the inlet flange tube 8 in the cylindrical shell 1 pass through either side of the center line of the inlet flange tube 8 The two valve stems 2 at the center of the circular gate 3 and the circular sealing plug 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com