Gear transmission device of GTF engine

A gear transmission and gear drive technology, applied in the direction of gear transmission, transmission, transmission parts, etc., to achieve the effect of increasing flexibility and radial floating effect, and ensuring radial floating and equalizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiments, but it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments. Without departing from the above-mentioned technical idea of the present invention, various substitutions and changes based on common technical knowledge and conventional means in the field shall be included in the protection scope of the present invention.

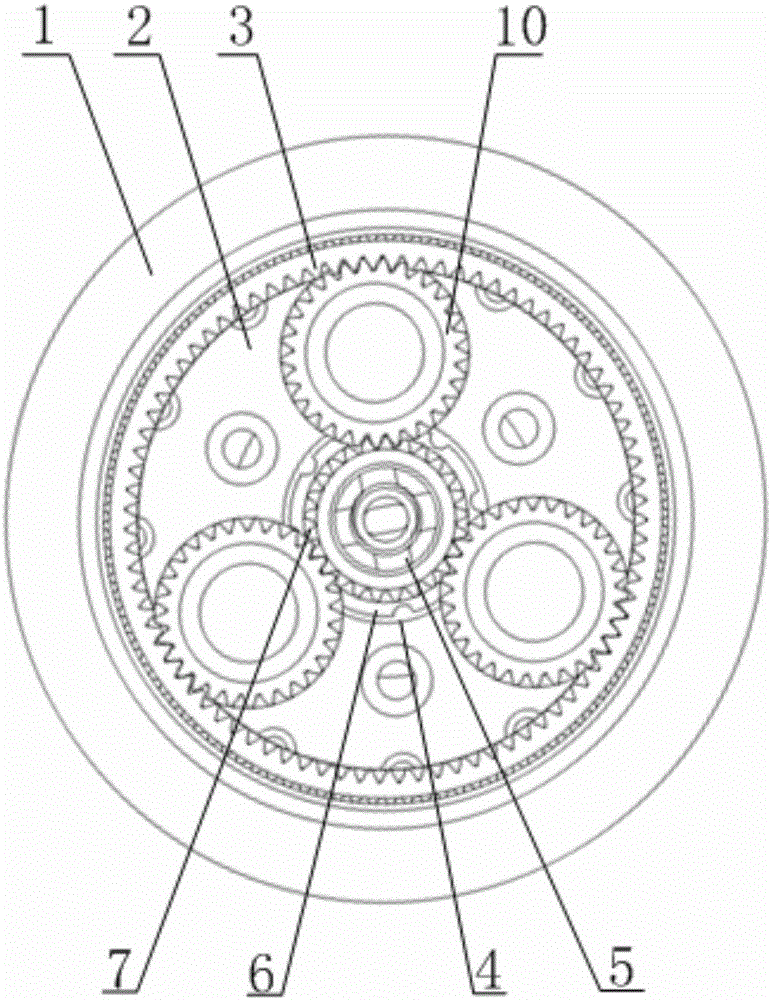

[0034] See figure 1 , A gear driven fan (GTF) engine gear transmission device, which mainly includes: planet carrier cover 1, planet carrier 2, herringbone ring gear 3, input spline sleeve 4, sun gear fixing nut 5, sun gear A6, sun Gear B7, planetary shaft 8, planetary shaft fixing nut 9, herringbone planetary gear 10, herringbone planetary gear bearing 11, transmission shaft 12, fan sleeve 13, cylindrical roller bearing 14 and radial ball bearing 15.

[0035] See figure 2 , A number of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com