Hydraulic control system for continuous lifting of ocean platform

A hydraulic control system and offshore platform technology, applied in the field of hydraulic systems, can solve problems such as increased control costs, and achieve the effects of reducing control costs and reducing flow requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

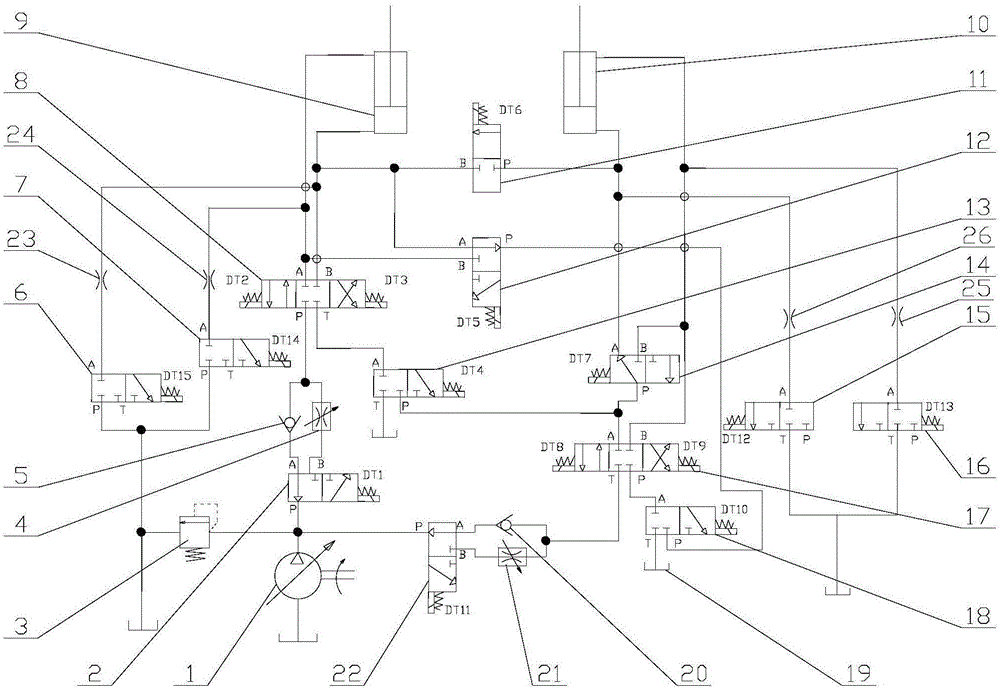

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The embodiment of the present invention provides a continuous lifting hydraulic control system for an offshore platform, which is suitable for the first lifting cylinder 9 and the second lifting cylinder 10 in the hydraulic continuous lifting system.

[0027] figure 1 It is a schematic diagram of the principle of the offshore platform continuous lifting hydraulic control system provided by the embodiment of the present invention, see figure 1, the hydraulic control system includes: oil tank 19, hydraulic pump 1, first three-position four-way reversing valve 8, second three-position four-way reversing valve 17, first two-two three-way reversing valve 14 and second two-way reversing valve Three-position reversing valve 12, the input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com