A fiber laying pressure roller capable of absorbing and blowing away carbon fiber prepreg tow and method thereof

A technology of carbon fiber prepreg and fiber laying, which is applied in the field of fiber laying press rollers and the production of components made of composite materials, which can solve the problems of sticking to the press rollers, increasing the size of prepreg tows, and affecting the quality of the layup And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

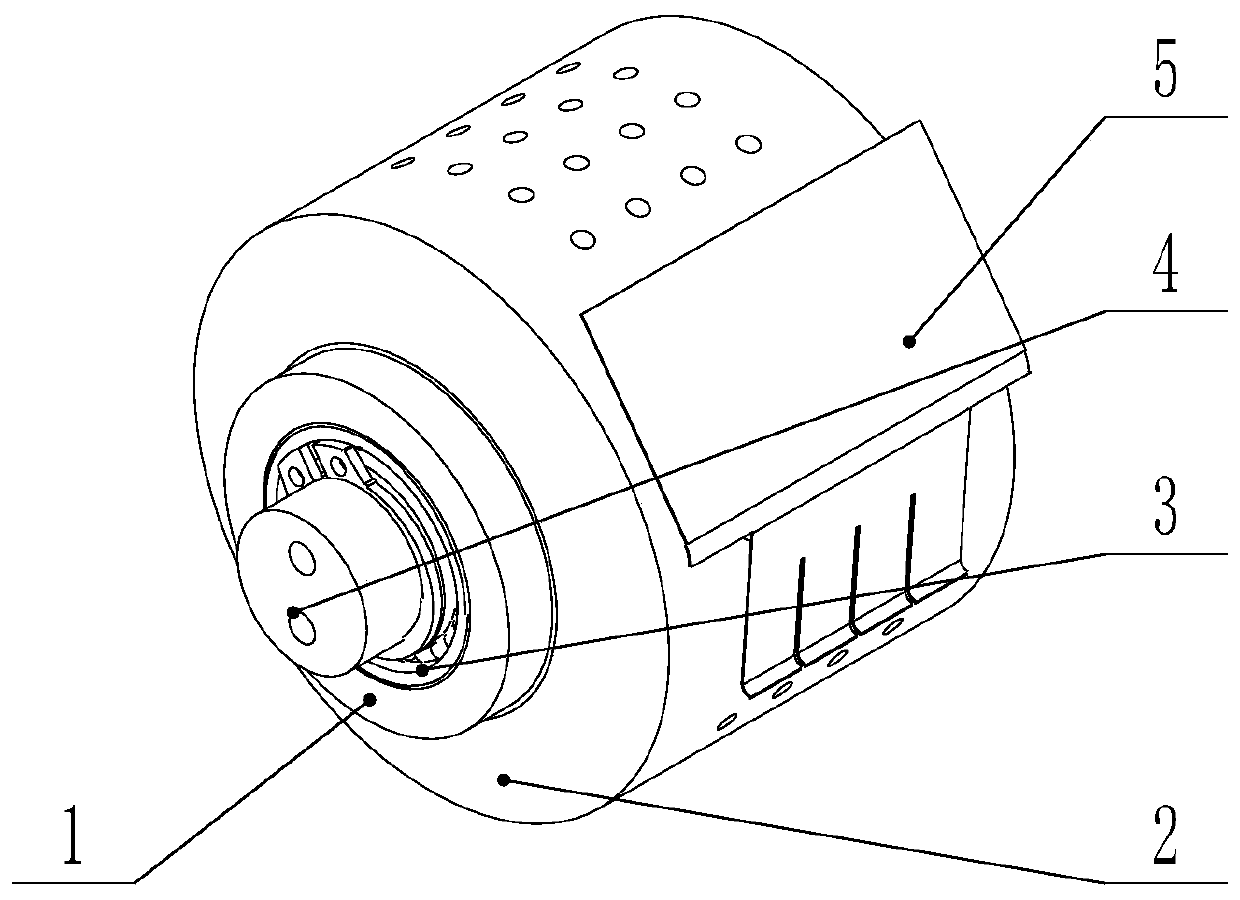

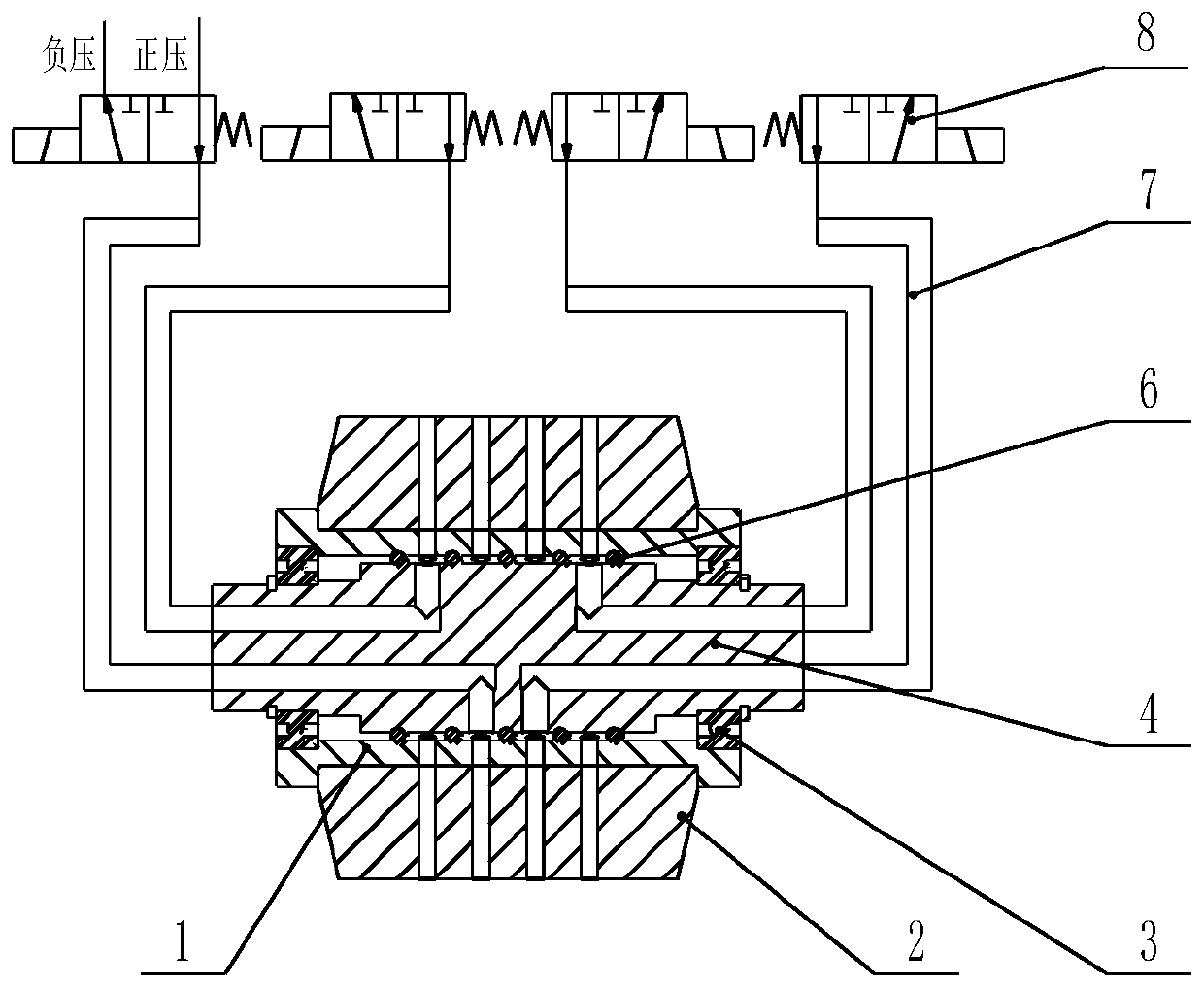

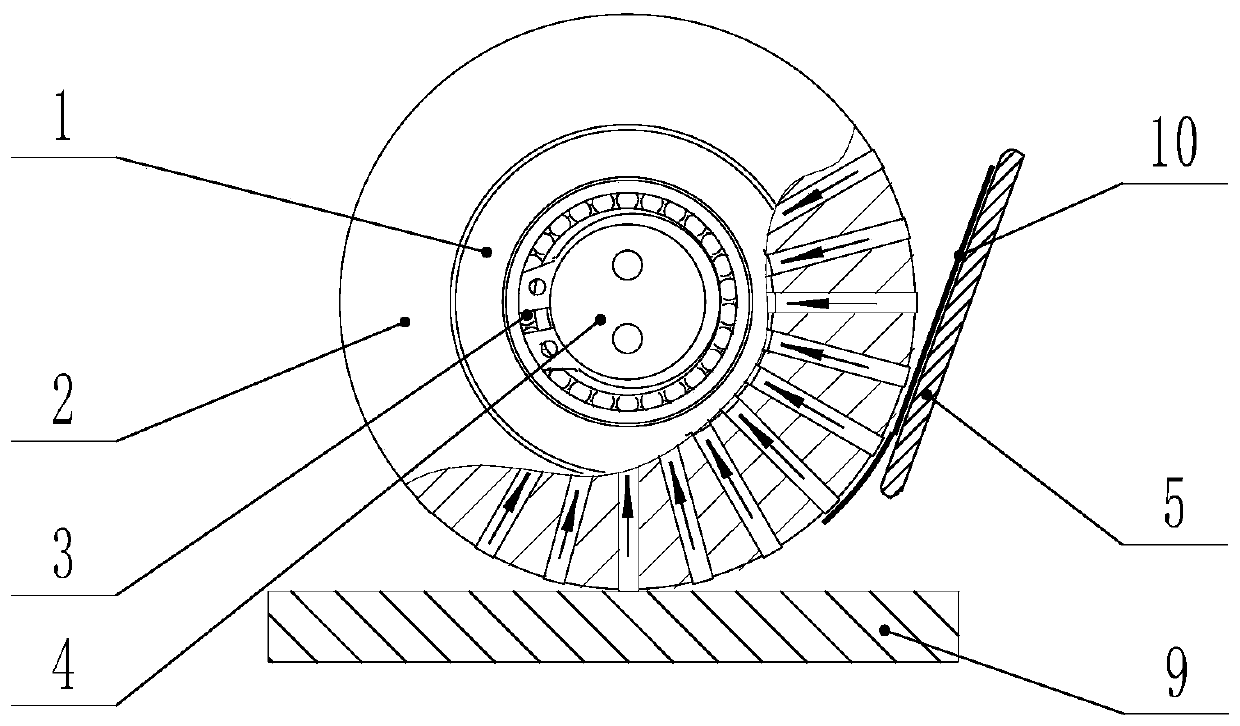

[0030] Such as figure 1 with figure 2 As shown, the fiber laying press roller capable of absorbing and blowing off carbon fiber prepreg tow of the present invention includes a press roller rigid body 1 sleeved on the press roller shaft 4, and the press roller rigid body 1 is made of carbon steel material. In order to provide sufficient support for the pressure roller during the laying process, a sealing ring 6 is arranged between the pressure roller shaft 4 and the pressure roller rigid body 1, and the sealing ring 6 seals the space between the pressure roller shaft 4 and the pressure roller rigid body 1 Axially divided into a plurality of mutually independent spaces, each space corresponds to each tow passage of the tow passage plate 5 in the axial position; the press roller rigid body 1 is fitted with a press roller elastic body 2 . The pressing roller elastic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com