Tension-controllable silicon steel monolithic coating sample sintering experimental device and method

An experimental device and tension technology, which is applied in the preparation of test samples, investigation phases/state changes, etc., can solve problems such as tension changes and inability to adjust, and achieve the effects of reducing errors and realizing orientation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

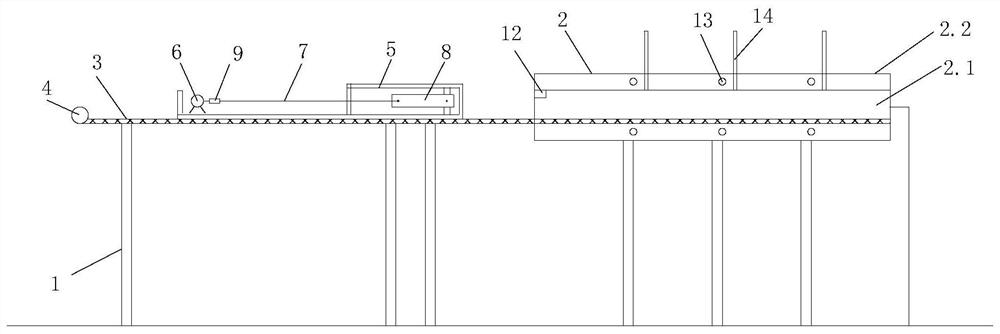

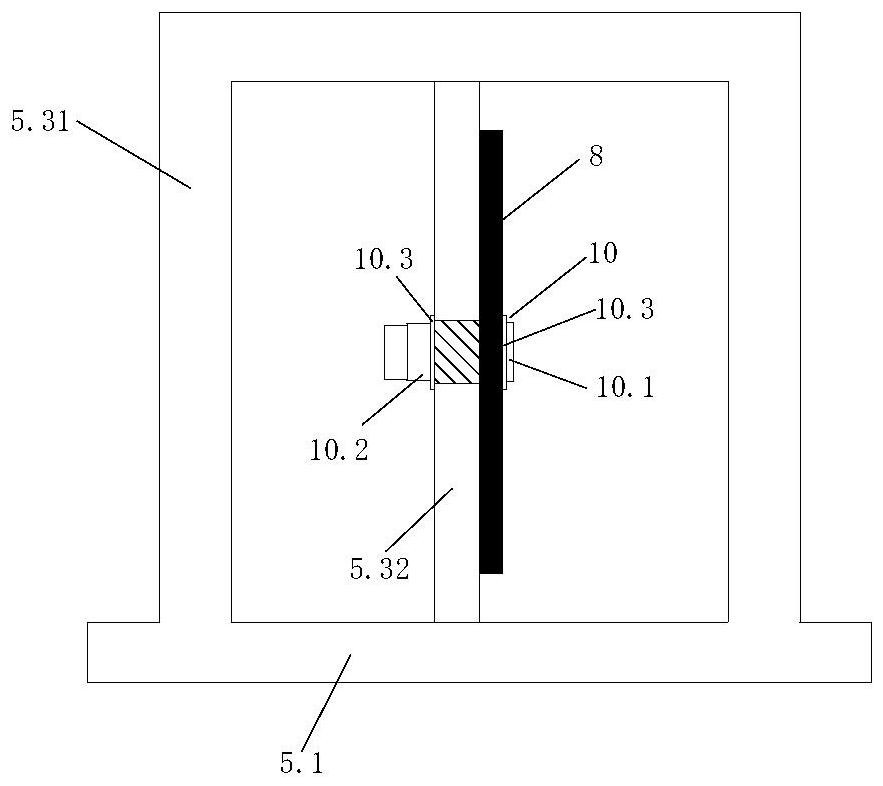

[0046] The present invention provides a kind of method that utilizes above-mentioned silicon steel monolithic coating sample sintering experimental device with controllable tension to conduct experiments, comprising the following steps:

[0047] 1) process the sample 8 to be tested, set the first mounting hole 8.1 at one end of the sample 8 to be tested, and open the second mounting hole 8.2 at the other end, the diameter of the first mounting hole 8.1 and the second mounting hole 8.2 is 8 mm, which can be It is carried out by bench drilling or laser cutting, and the burr on the edge of the hole and the geometric edge of the sample is ensured to be less than 10μ, and then the test sample 8 is coated by roller coating or manual roller coating, and the H coating liquid or T coating liquid used is Existing commercially available coating liquid, and measure the initial magnetism I before coating of sample 8 to be tested;

[0048] 2) Send the coated sample 8 into a drying oven at a...

Embodiment 2

[0058] The present invention provides a kind of method that utilizes above-mentioned silicon steel monolithic coating sample sintering experimental device with controllable tension to conduct experiments, comprising the following steps:

[0059] 1) process the sample 8 to be tested, set the first mounting hole 8.1 at one end of the sample 8 to be tested, and open the second mounting hole 8.2 at the other end, the diameter of the first mounting hole 8.1 and the second mounting hole 8.2 is 8 mm, which can be It is carried out by bench drilling or laser cutting, and the burr on the edge of the hole and the geometric edge of the sample is ensured to be less than 10μ, and then the test sample 8 is coated by roller coating or manual roller coating, and the H coating liquid or T coating liquid used is Existing commercially available coating liquid, and measure the initial magnetism I before coating of sample 8 to be tested;

[0060] 2) Send the coated sample 8 into a drying furnace w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com