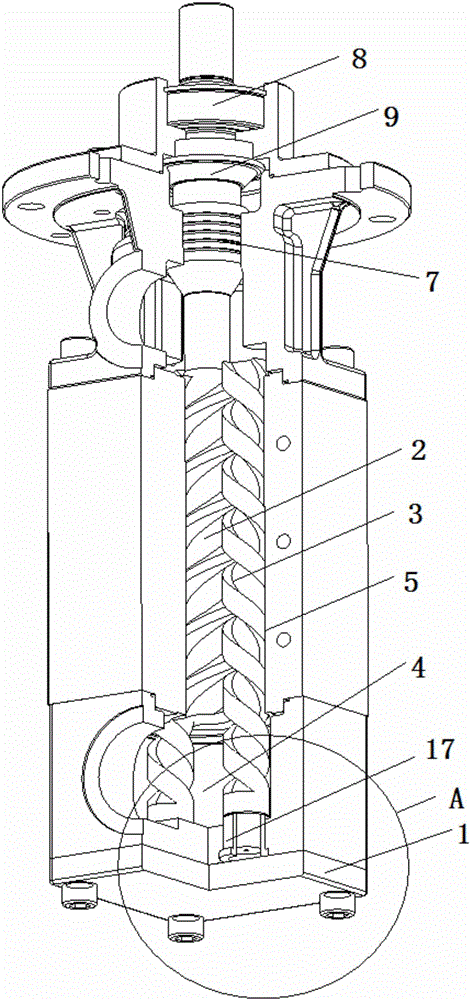

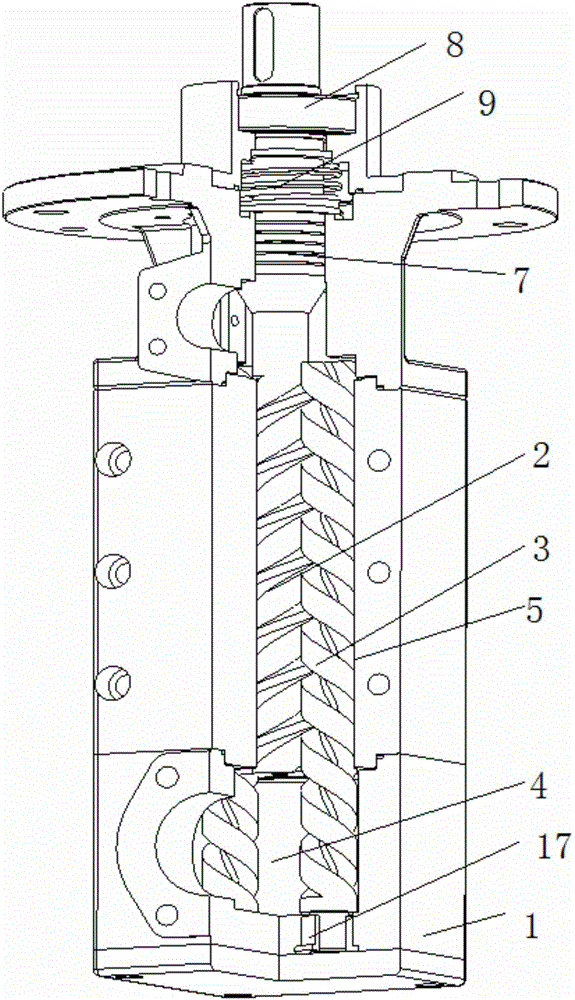

Screw pump with low viscosity and high pressure

A high-pressure, low-viscosity technology, used in pumps, rotary piston/oscillating piston pump parts, pump components, etc., which can solve the problem of axial force, centrifugal force, large radial force, simple, compact and durable structure. Economical and durable problems, to achieve the effect of reducing friction, reducing power, energy saving and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

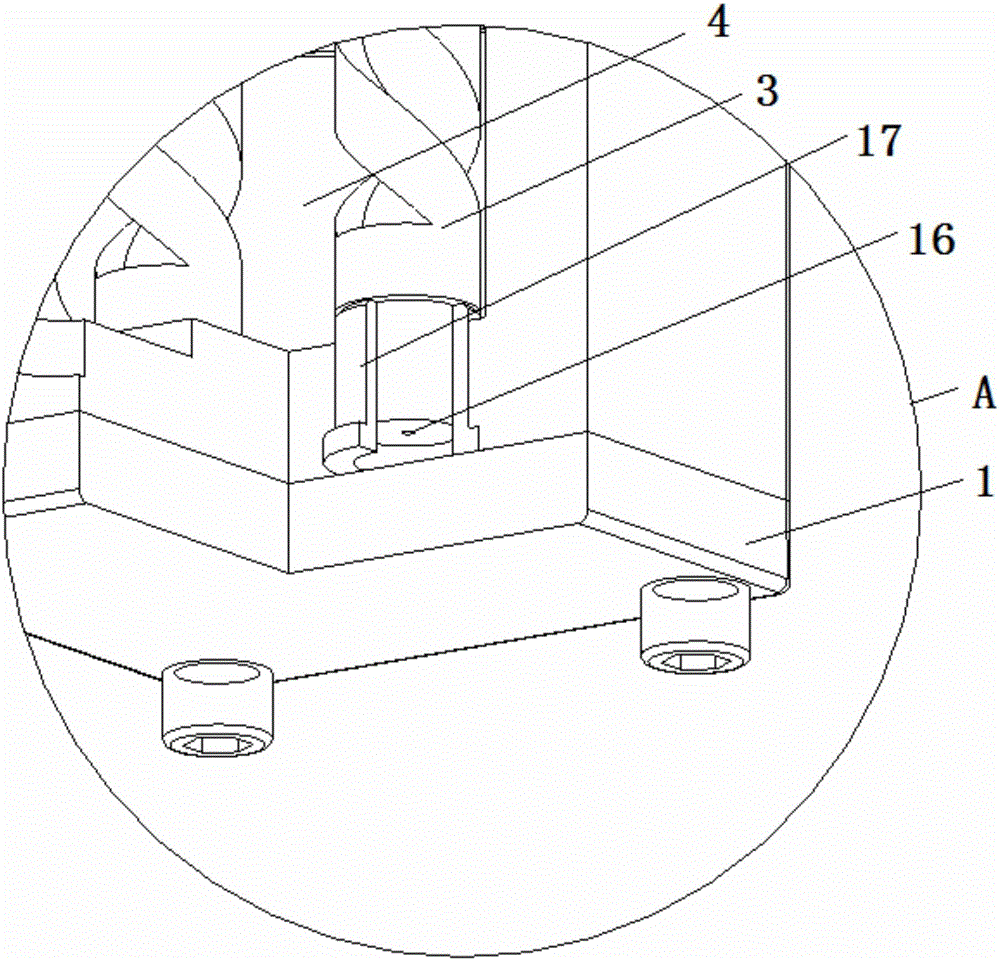

[0027] Embodiment 2 is the same as Embodiment 1, except that the bottom of the pump chamber 4 is provided with a balance weight matched with the driven screw 3 instead of the positioning sealing sleeve 17 . The balance weight is made of hardened hardened steel or silicon carbide or tungsten steel.

[0028] Low-viscosity and high-pressure screw pumps have a flow rate of 1-1000 liters per minute, a working pressure of 1-15Mpa, a maximum inlet pressure of 2Mpa, a maximum working temperature of 130°C, and a kinematic viscosity of 1-2500㎜2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com