Prefabricated member building and construction process thereof

A kind of construction technology and assembly technology, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of being unable to keep up with the pace of building industrialization, the high cost of the grid structure system, and being easily affected by the weather. Achieve the effects of improving on-site dust phenomenon, facilitating quality control, and reducing construction difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

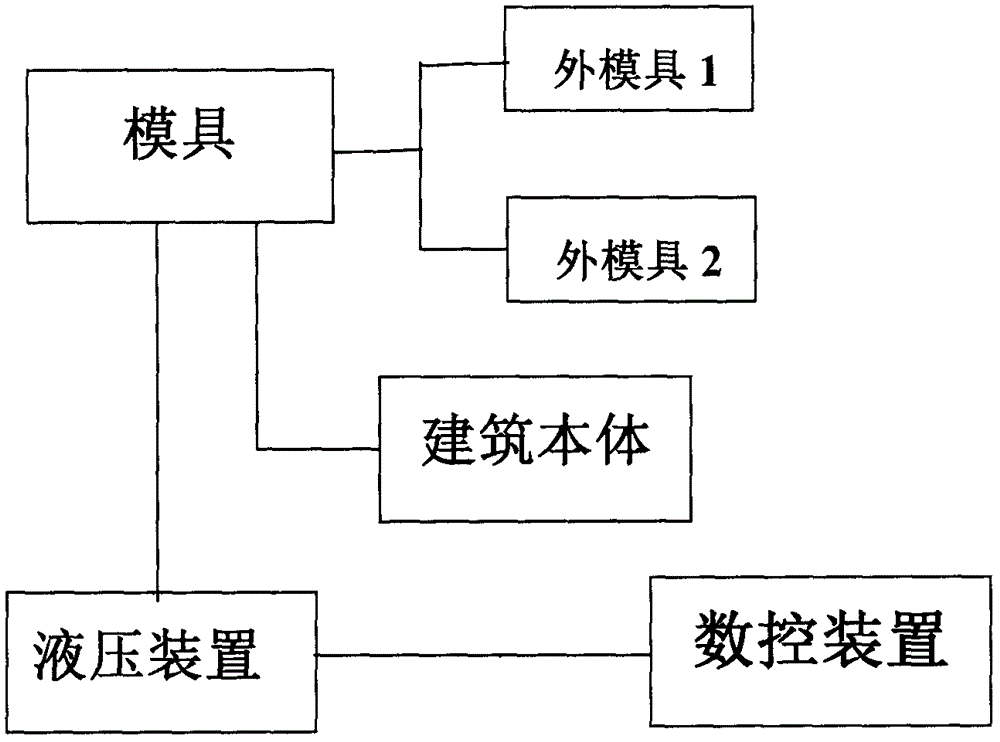

Method used

Image

Examples

Embodiment example

[0043] The high-rise 36# building in Xinxiang Muye Community has an area of 24997.56 square meters and 31 floors in total. The tower crane carries out component hoisting. When hoisting, use a special steel shoulder pole, connect with the components through steel wire ropes and lifting rings, use the tower crane arm to lift at a constant speed and slowly rotate to the floor. After reaching the floor, the installation workers install the components in place through the wind rope and adjusting bolts.

[0044] In the residential design stage, various components are disassembled into standard components, prefabricated and processed in the production workshop to form prefabricated concrete exterior wall panels and balconies with decorative surfaces and insulation layers, internal wall panels with pipeline application functions and other component parts .

[0045] This residential building has been built to 17 floors, and an average of one floor can be built every 4 days. Using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com