Construction equipment for concrete piles and construction method of construction equipment

A kind of construction equipment and concrete pile technology, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems that it is difficult to form the design depth of the pile hole, the original soil is not fully utilized, and the next step of construction cannot be carried out, etc., to achieve Reduce the link of soil clearing and transportation, wide application range and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

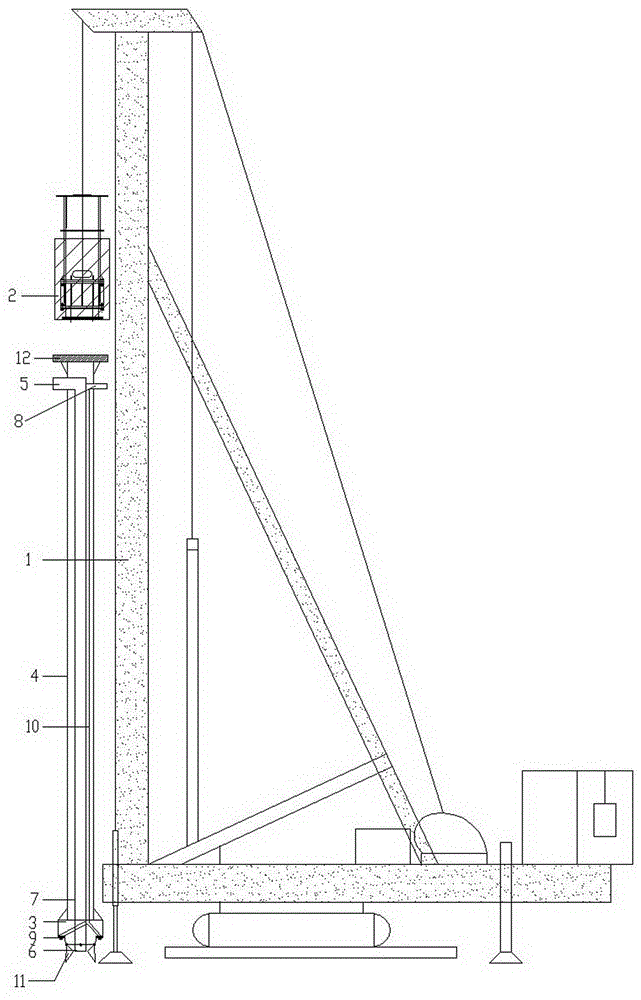

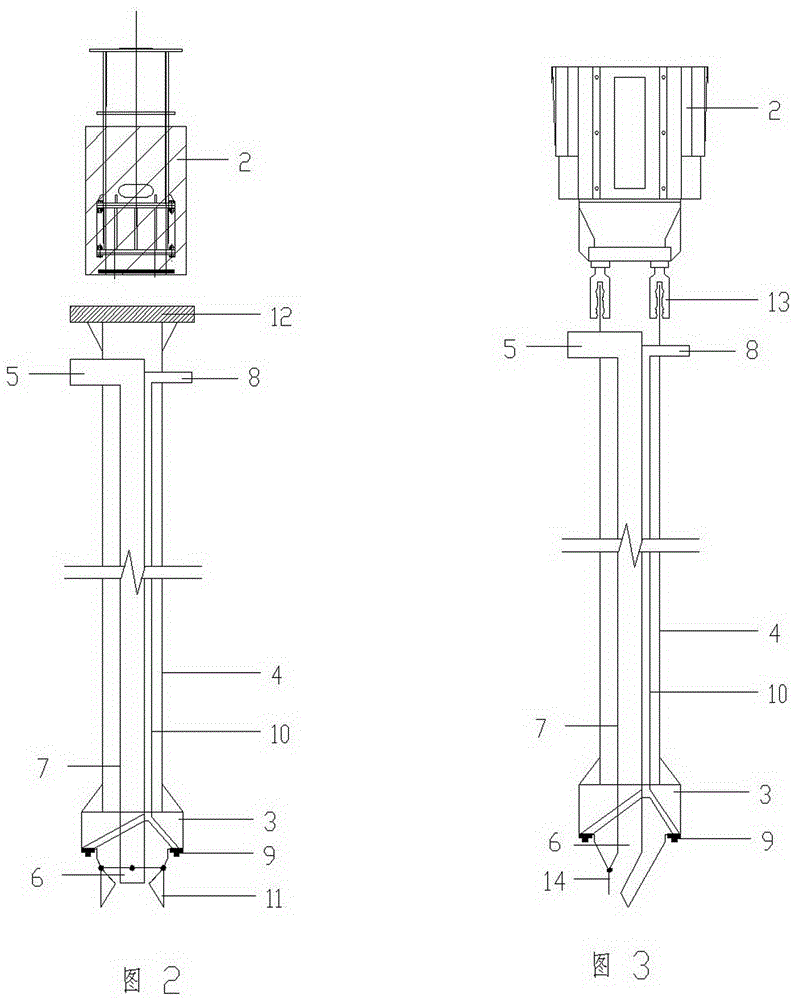

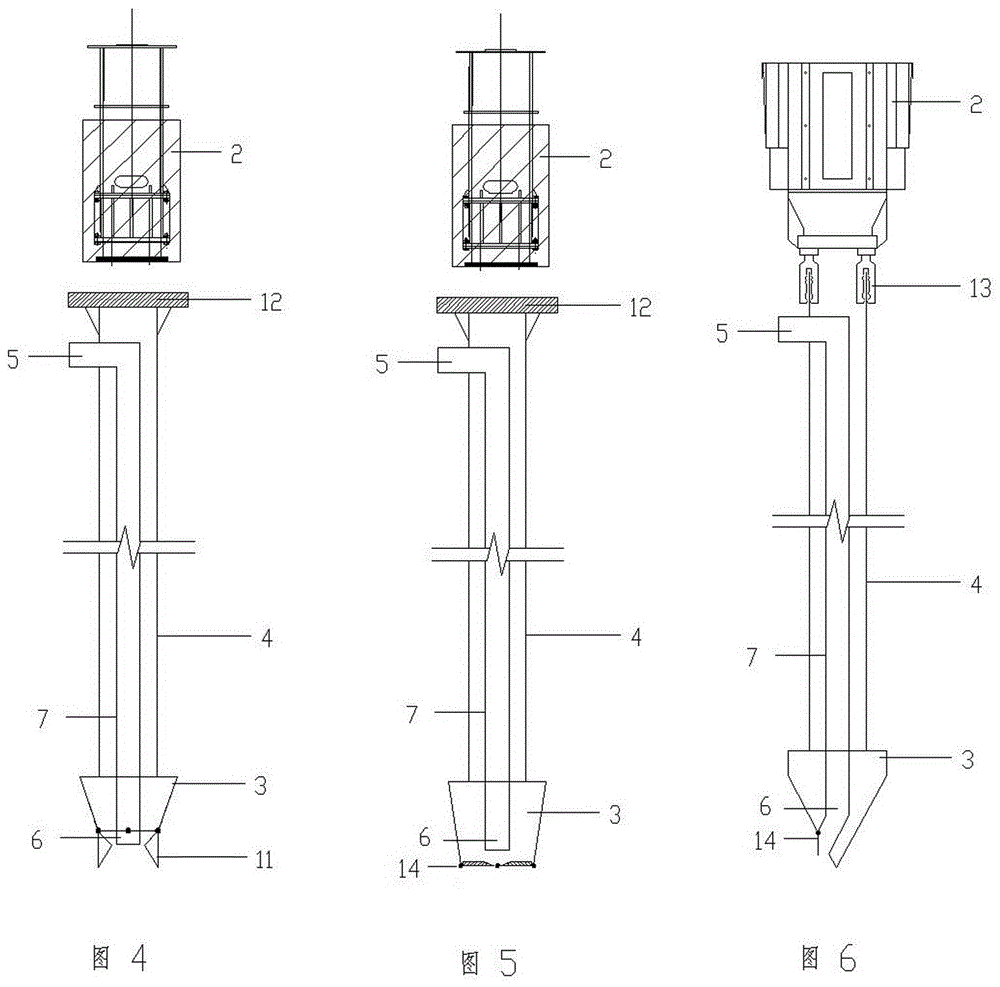

[0029] figure 1 It is a schematic diagram of a preferred embodiment of the construction equipment of the concrete pile of the present invention, as figure 1 As shown, the construction equipment includes a frame 1, a power hammer 2, and a stamping device. The frame 1 adopts a long auger drill. 2. Diesel hammer is used. The stamping device is located under the power hammer (2) and can move up and down along the vertical rod. The stamping device includes impact hammer head 3, hollow rod 4, feeding device, and grouting device; impact hammer head 3 is fixed At the bottom of the hollow rod 4, the lower part of the impact hammer 3 has a valve tip 11 that can be opened and closed; the diameter of the hollow rod 4 is smaller than that of the impact hammer 3, and the top of the hollow rod 4 is provided with a rammer. The striking plate 12 is convenient for the impact of the power hammer 2; the feeding device includes a feeding pipe 7 with a feeding port 5 and a feeding port 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com