Liquid absorption fiber

A fiber and fiber cross-section technology, applied in the fiber field, can solve the problems of insufficient fiber liquid absorption, harsh reaction conditions, loss of liquid absorption function, etc., achieve good liquid absorption performance and antibacterial performance, mild reaction conditions, and liquid absorption capacity Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

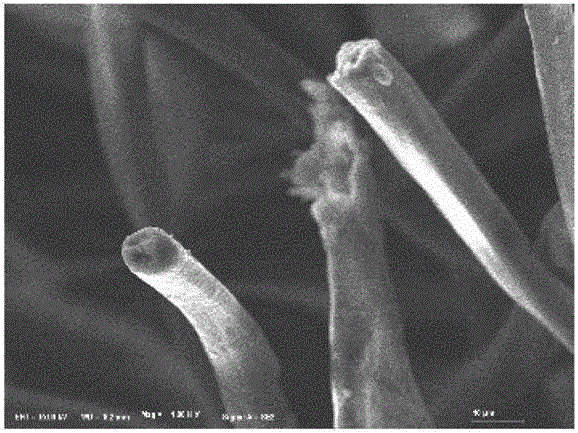

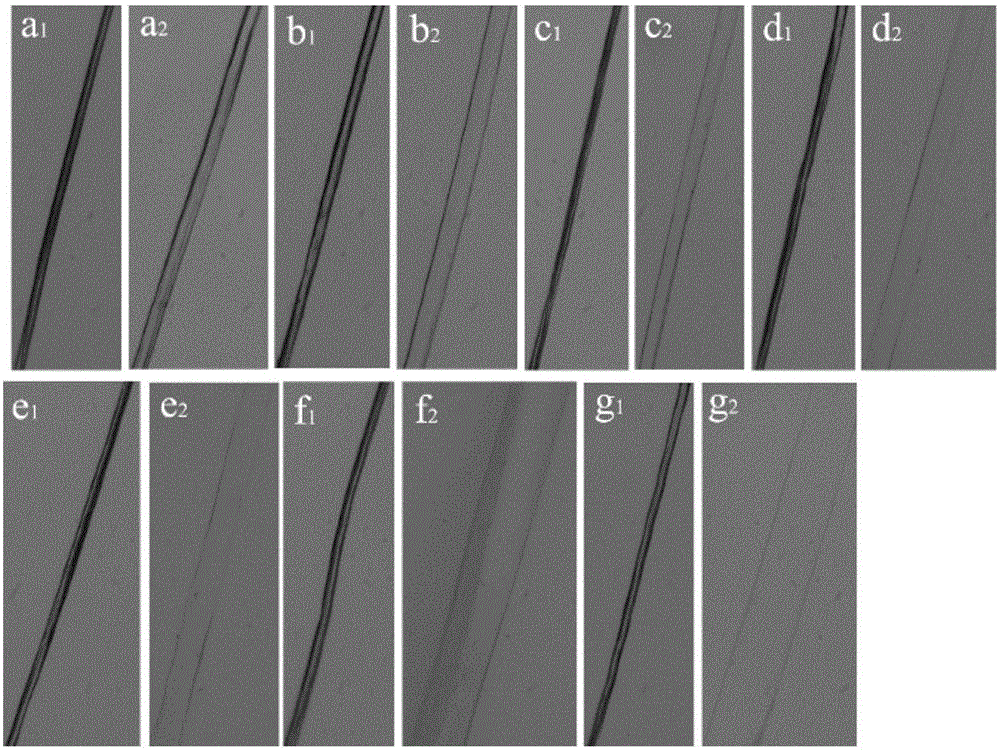

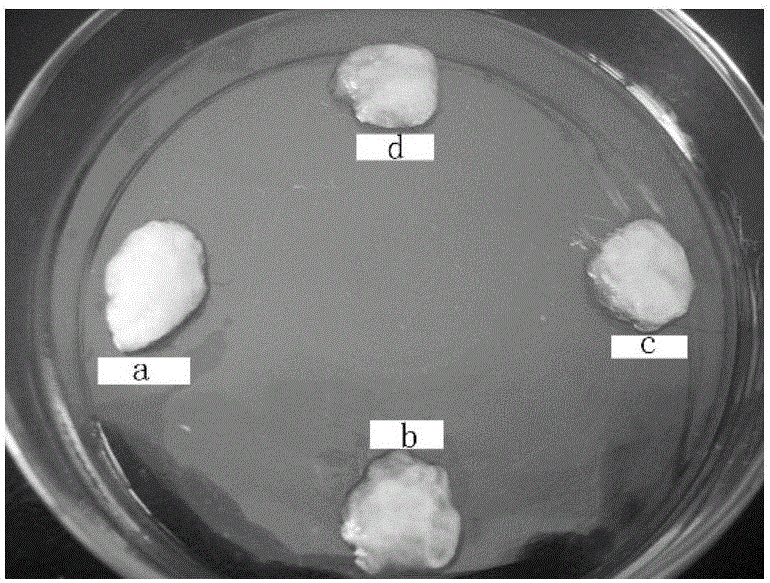

[0088]Weigh 5 g of chitin fibers with a length of 6 cm and a p / (m+n+p) of 0.25, disperse them in 50 mL of isopropanol, add 2.54 g of 2-hydroxyethyl acrylate, and shake evenly at room temperature. React in a constant temperature water bath for 48 hours under the same conditions, separate the reacted chitin fibers from the reaction mixture, wash twice with 80% (v / v) methanol aqueous solution, take out the fibers, dry them, and disperse them in 80% (v / v) v) Add 30% (w / v) potassium hydroxide aqueous solution dropwise to methanol aqueous solution, adjust the pH of methanol and potassium hydroxide aqueous solution mixture to 11.0, soak for 1 hour, and then separate the soaked fiber from the mixture , washed three times with 80% (v / v) methanol aqueous solution, dehydrated, and dried at 40°C to obtain the viscosity average molecular weight (M η ) 3 million, a liquid-absorbent fiber with a substitution degree of 0.17 for the total amount of acryl group.

[0089] Dissolve absorbent fib...

Embodiment 2

[0091] Weigh 5 g of chitin fibers with a length of 6 cm and a p / (m+n+p) of 0.10, disperse them in 50 mL of isopropanol, add 7.09 g of 2-hydroxypropyl acrylate, and shake evenly at room temperature. React in a constant temperature water bath for 48 hours under the same conditions, separate the reacted chitin fibers from the reaction mixture, wash twice with 80% (v / v) methanol aqueous solution, take out the fibers, dry them, and disperse them in 80% (v / v) v) Add 30% (w / v) potassium hydroxide aqueous solution dropwise to methanol aqueous solution, adjust the pH of methanol and potassium hydroxide aqueous solution mixture to 11.0, soak for 1 hour, and then separate the soaked fiber from the mixture , washed three times with 80% (v / v) methanol aqueous solution, dehydrated, and dried at 40°C to obtain a liquid-absorbent fiber with a viscosity-average molecular weight of 3 million and a degree of substitution of acryl group total substance of 0.30.

[0092] Dissolve absorbent fibers ...

Embodiment 3

[0094] Weigh 5 g of chitin fibers with a length of 6 cm and a p / (m+n+p) of 0.10, disperse them in 50 mL of isopropanol, add 14.17 g of 2-hydroxypropyl acrylate, and shake evenly at room temperature. React in a constant temperature water bath for 48 hours, separate the reacted chitin fibers from the reaction mixture, wash twice with 80% (v / v) methanol aqueous solution, take out the fibers, dry them, and disperse them in 80% (v / v) Add dropwise 30% (w / v) potassium hydroxide aqueous solution to methanol aqueous solution, adjust the pH of methanol and potassium hydroxide aqueous solution mixture to 11.5, soak for 1 hour, then separate the soaked fiber from the mixed solution, shake dry, then placed in saturated CaCl 2 Soak in the solution for 1 hour, take out the fiber, wash 3 times with 80% (v / v) methanol aqueous solution, and dry at 40°C after dehydration to obtain a viscosity-average molecular weight of 500,000 and a total substitution degree of acryloyl group of 0.49 absorbent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com