Method for preparing graphene electrode in high-temperature piezoelectric sensor

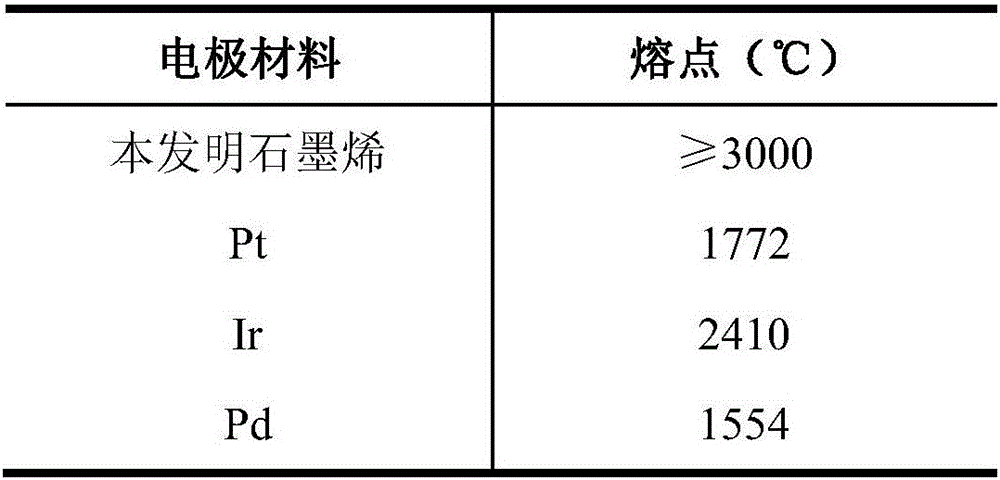

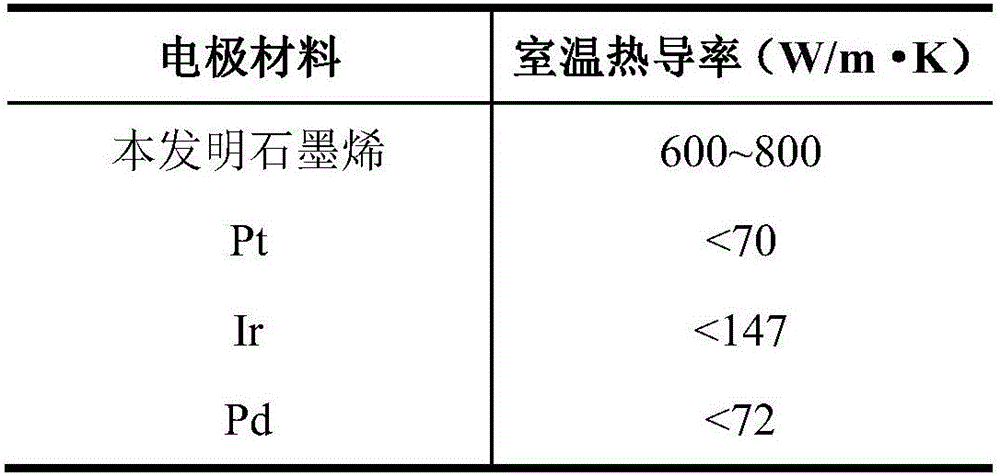

A graphene electrode, high temperature piezoelectric technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of general performance and high price of electrode materials, and save the film transfer process and price. Expensive, low temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Sonicate the ground and polished BTS wafer with deionized water, acetone, and ethanol for 10 minutes, take out the wafer, and compress it with N 2 Put the gas into the plasma chemical vapor deposition chamber after drying its surface, close the chamber, and start the vacuum pump; until the air pressure in the chamber drops to 10 -5 Below Torr, pass Ar and CH 4 Gas, control Ar gas flow to 100sccm, CH 4 The flow rate was 10 sccm and the pressure in the conditioning chamber was 1 Torr. Start the heating power supply of the chemical deposition chamber, and set the temperature rise program as follows: the room temperature is raised to 400°C, and the temperature is kept constant for 15 minutes; the heating rate is 10°C / min, and the constant temperature is 25 minutes at 250°C; the plasma source is turned on, and the constant temperature is deposited at 400°C for 30 minutes, and the obtained Graphene electrodes.

[0023] The adhesion between the graphene electrode and the hi...

Embodiment 2

[0025] Sonicate the ground and polished LGS wafer with deionized water, acetone, and ethanol for 15 minutes, take out the wafer, and compress it with N 2 Put the gas into the plasma chemical vapor deposition chamber after drying its surface, close the chamber, and start the vacuum pump; until the air pressure in the chamber drops to 10 -5 Below Torr, pass Ar and CH 4 Gas, control Ar gas flow to 75sccm, CH 4 The flow rate was 25 sccm and the pressure in the conditioning chamber was 0.5 Torr. Start the heating power supply of the chemical deposition chamber, and set the heating program as follows: the room temperature is raised to 700°C, and the temperature is kept constant for 20 minutes; Deposit for 80min to obtain a graphene electrode.

[0026] The adhesion between the graphene electrode and the high-temperature piezoelectric chip is strong, and it is found that there is almost no graphene peeling off after repeated adhesive tape. After testing, the resistivity of the gra...

Embodiment 3

[0028] Sonicate the ground and polished LGT wafer with deionized water, acetone, and ethanol for 12 minutes, take out the wafer, and compress it with N 2 Put the gas into the plasma chemical vapor deposition chamber after drying its surface, close the chamber, and start the vacuum pump; until the air pressure in the chamber drops to 10 -5 Below Torr, pass into Ar and C 2 h 6 Gas, control Ar gas flow to 50sccm, C 2 h 6 The flow rate was 50 sccm and the pressure in the conditioning chamber was 0.05 Torr. Start the heating power supply of the chemical deposition chamber, and set the heating program as follows: the room temperature is raised to 500°C, and the temperature is kept constant for 18 minutes; the heating rate is 20°C / min, and the temperature is kept at 250°C for 25 minutes; the plasma source is turned on, and the constant temperature is deposited at 500°C for 150 minutes, and Graphene electrodes.

[0029] The adhesion between the graphene electrode and the high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com