Installation method for blast furnace bottom water cooling beam and blast furnace bottom water cooling pipe

An installation method and technology of water-cooled beams, which are applied to cooling devices and other directions, can solve problems such as poor construction conditions on site, difficulty in reinforcement, and heavy workload, and achieve the effects of ensuring manufacturing quality, reducing construction procedures, and small welding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Such as figure 1 Shown, the blast furnace bottom water-cooled beam of the present invention and the installation method of water-cooled pipe comprise the following steps:

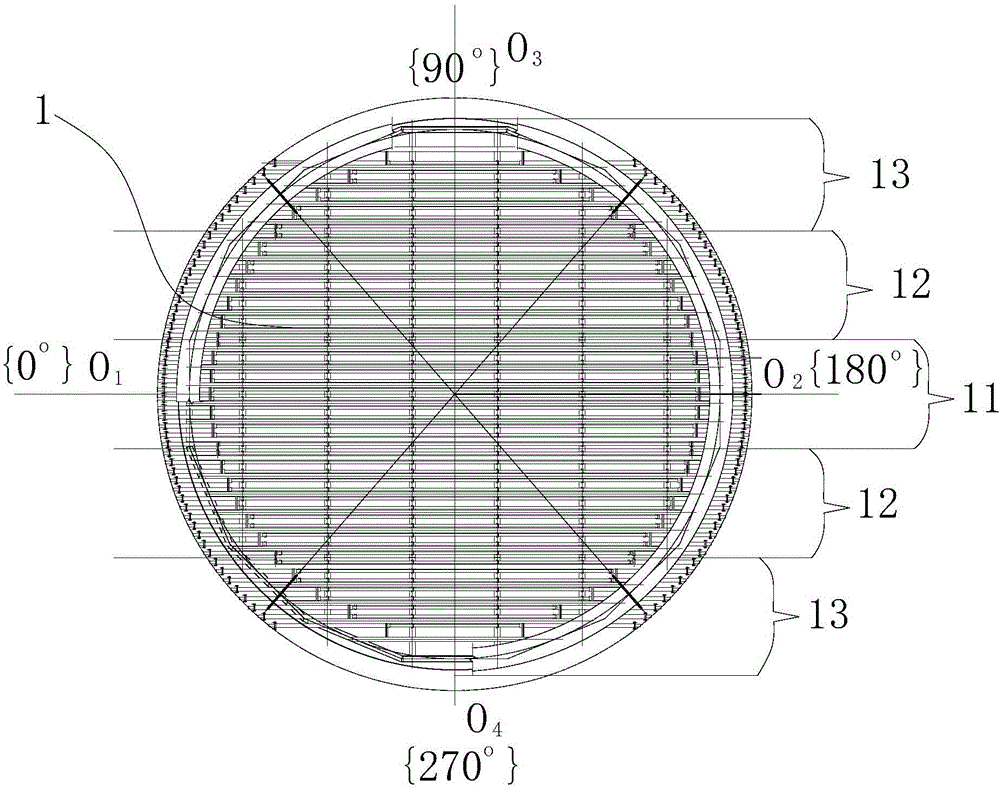

[0027] 1) According to the design drawings, the bottom water-cooled beam and water-cooled tube assembly 1 is aligned along the 0°-180° axis O 1 o 2 In the parallel direction, it is divided into five splicing blocks, and the five splicing blocks include splicing block one 11, two splicing blocks two 12 and two splicing blocks three 13;

[0028] The two splicing blocks 12 are respectively located on both sides of the splicing block one 11, and the two splicing blocks 12 are located between the splicing block one 11 and the splicing block 13; the two splicing blocks two 12 and the two splicing blocks 13 are about the axis O 1 o 2 Symmetry; the first splicing block 11, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com